November 7, 2023

Interest Needed! Cloudflare

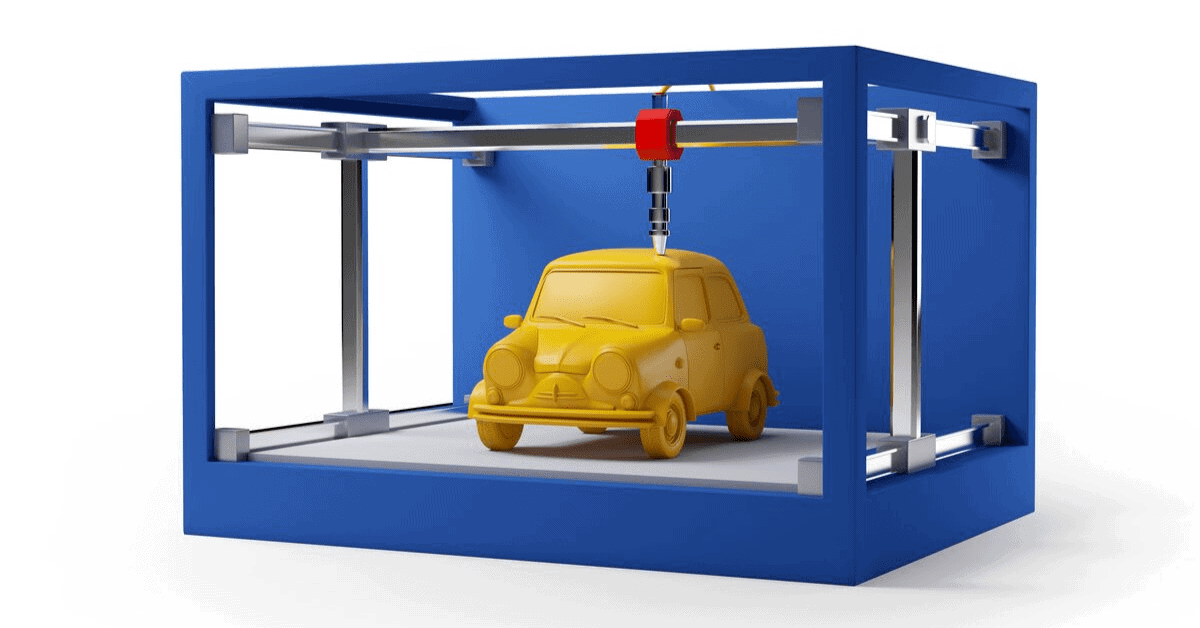

3d Printing Tips + Much Easier Cad And printers should be kept to obtain the best print. For instance, the printer's rails need to be cleansed as well as oiled. And the gantry ought to go to the very same height on both sides if your printer uses stepper electric motors. Likewise, inspect to see if there are any kind of weak spots in the frame. Tighten up all bolts and also make certain the firmware upgraded according to the manufacturer's recommendations.How do I get a great surface area coating in 3D printing?

Industrial Composite 3d Printers

It's a common recommendation to tighten your belts yet this can be conveniently overtightened. By doing this, you are executing the modification with the same conditions as when printing. The bed and the nozzle expand by a percentage when warm.Gridfinity Modular Storage System: All You Need to Know - All3DP

Gridfinity Modular Storage System: All You Need to Know.

Posted: Sat, 25 Feb 2023 08:00:00 GMT [source]

Pointers For 3d Printing Pla

It's far better to over-inform than under, because perhaps that a person setting that appears unimportant to you is actually the entire factor your 3D print isn't appearing right. The temperature reported by the thermistor from a printer's hotend is not as precise as you may anticipate. Sometimes, the actual temperature level inside the heatblock can range in between 10C to 15C from the one reported by the thermistor. Besides that, using nozzles with different materials can affect the temperature level you require to make use of for some filaments.How to Make 3D Printed Car Parts - MUO - MakeUseOf

How to Make 3D Printed Car Parts.

Posted: Sat, 18 Feb 2023 08:00:00 GMT [source]

Prepared To Transform Your Cad Documents Into A Customized Component? Publish Your Designs For A Cost-free, Instantaneous Quote

Gradually, you may discover yourself creating your 3D versions to not require assistances whatsoever and also instead utilize clever design methods to circumvent the need for support frameworks. 3 points define an aircraft, but many printers still utilize four screws to level the bed, with one at each edge. This can still work, it's simply a little bit more difficult to obtain it ideal. If you currently have your printer installed on a shaky surface area, you will certainly be able to boost print high quality by moving the printer on an extra steady surface area. This modification will certainly equate right into less motion and totter for your printer which will certainly generate better top quality 3D prints.- Bigger nozzles function best for prints without slim or great information because they print thicker layers.

- Update your last CAD model with the specification you discover works best, as well as print it with self-confidence that it will prosper.

- Purpose your spatula away from on your own when you are removing 3D prints.

- Wall thickness goes hand-in-hand with non-manifold geometries, as we saw above, geometries without quantity can not be made.

- Ensure the extruder has the area to relocate so the printed location does not overheat or develop other high quality troubles.

Social Links