November 7, 2023

3d Printer Troubleshooting Guidelines To Fix Issues With 3d Printing

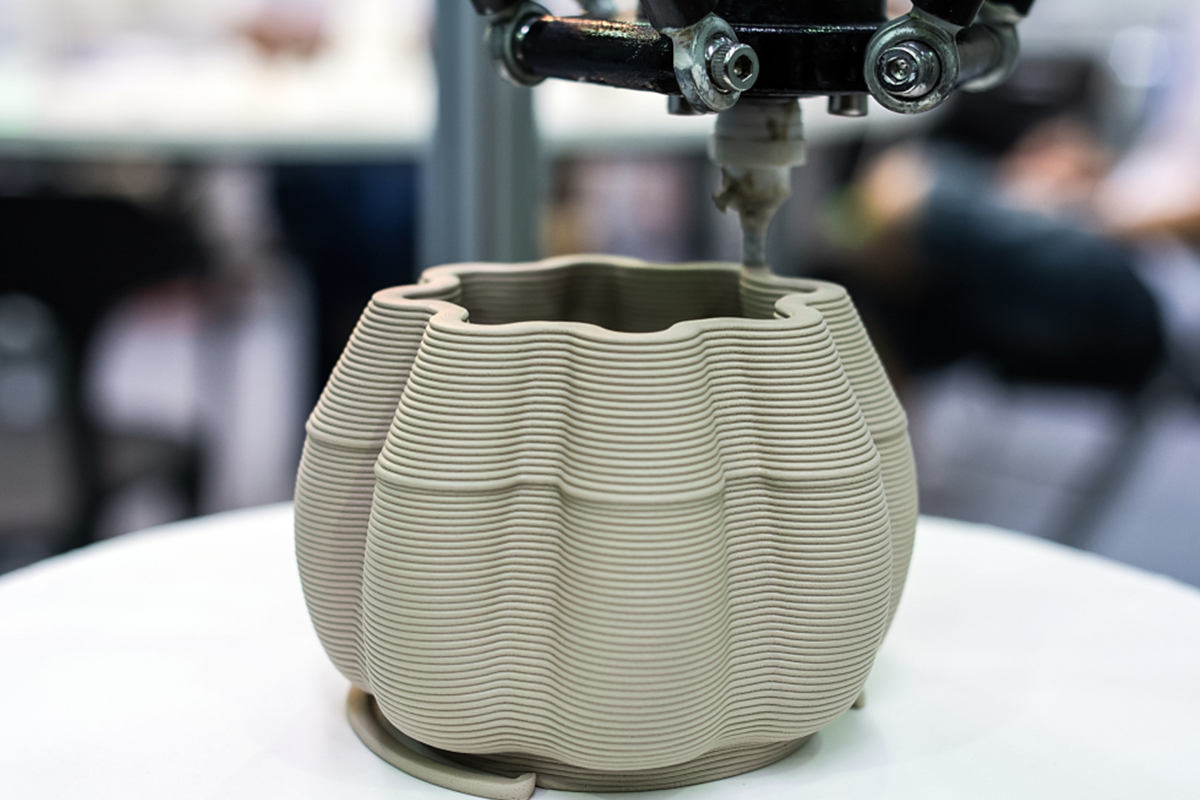

3d Printer Fixing Guide If the range is undue, the filament might not be offered for printing; if the distance is also tiny, the retraction may not be effective in quiting stringing. As a result, you need to conduct trial and error experiments to determine the perfect range. Once you find the suitable range, you will get rid of the stringing problem. A very first layer adhesion problem takes place when the initial layer of a print does not abide by the bed.- For materials that call for a heated bed, keep the fan rate low or transform it off completely for the first couple of layers.

- Ensure to turn your printer off as well as inspect the printed head manually, moving it in X-Y axes.

- This list of variables also stands for whatever that can be altered and kept in the EEPROM without the demand for firmware compilation.

Best 3d Designs 2023 With Stl Apply For 3d Printing

Filament top quality is important also-- if it's run out, after that it may not bond well between layers or the extrusion will be split. Envision a basic bridge version with thin uprights and think of the assistances. There are numerous opportunities, but the likeliest reason is the negative quality of your filament. Although several products are developed to be durable, storage space conditions matter. For example, subjecting filaments to direct sunlight for a long time will certainly make it weak. If you feed this product right into your system, no adjustments will certainly alter anything incorrect.Mass 3D Printing for Microchip Packaging Enabled with New Optomec Software - 3DPrint.com

Mass 3D Printing for Microchip Packaging Enabled with New Optomec Software.

Posted: Wed, 15 Mar 2023 07:00:00 GMT [source]

Just How To Take Care Of: The Nozzle Is Also Near To The Print Bed

If the nozzle is still obstructed, after that the filament might be pressed with an additional piece. Warm up the warm end to 220 ° C if you're reusing PLA as well as make use of an additional bit of brand-new filament to push this via. Yet don't do it also hard, so you can stay clear of bending the printer rods. The symptoms are very easy to neglect-- spots of filament or nicks in the wall surfaces as well as print quality changes. The results are typically ignored as well as credited to a variative nature of 3D printing, however in some cases the reasons are severe. Cleaning methods such as Atomic Pull or Cold Pull can assist remove it.What should I check before 3D printing?

You'll additionally discover that when PLA goes bad, it obtains brittle as well as easily snaps off.

Blobs As Well As 3d Printing Pimples

The cool temperature makes the plastic shrink, so it deforms contrasted to what was already published. If you have time for this degree of oversight, it's excellent since you can turn off the fan once everything is trendy to enable the following layer to stick. If you can not enjoy your printer job, you could intend to lower the filament's temperature so it will not proceed thawing once it's in area.Social Links