November 7, 2023

3d Printer Troubleshooting Guide

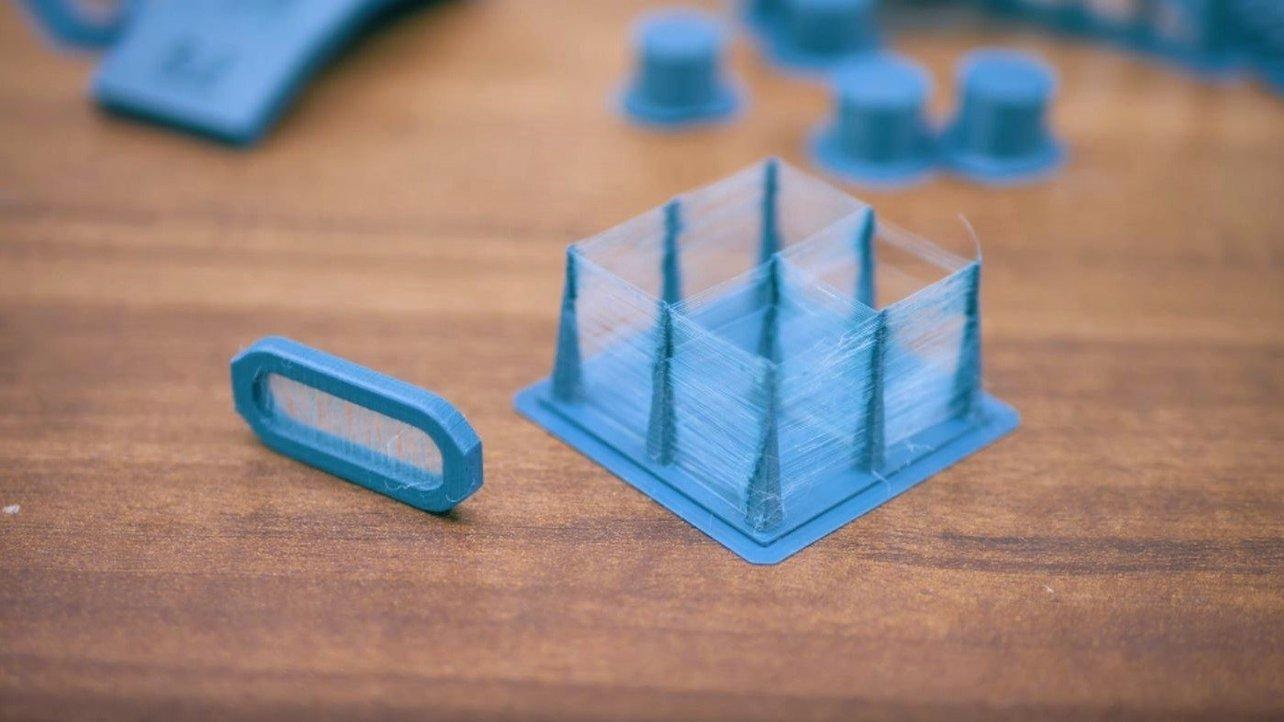

7 Most Common Troubles With A 3d Printer How To Take Care Of This may produce a lots too high for the ranked torque of the stepper. Without steppers, the stages need to move with less than 100 grams of pressure. Most of you may not also be considering this parameter to publish infills. If you take control of the slicer settings as well as print the infill with a larger extrusion width, you can enhance the toughness of the infill.3D Printing Financials: Velo3D Misses Earnings and Adjusts Full Year Guidance - 3DPrint.com

3D Printing Financials: Velo3D Misses Earnings and Adjusts Full Year Guidance.

Posted: Wed, 09 Nov 2022 08:00:00 GMT [source]

Detachment From Printbed

After that, you should sustain the print base for behind, and a wall is a perfect fit. Proceed as well as use the blade to remove the sides as well as at last insurance claim your printed model. The boost of publishing speed typically improves the time-efficiency, aids with filament flowing and lets you conserve time. Nevertheless, the rest of your printer might just be incapable to keep up the speed. When in the center of 3D-printing process, attempt paying attention to your surrounding.- Glass beds do have a tendency to be flatter, in addition to a PEI surface.

- In this case the multimeter will show when the two probes are connected by the display.

- Learn the recommended temperature level range for the product you make use of as well as establish the hotend temperature level to its minimum value.

Signs Of Leaning Prints:

Too slim as well as there isn't enough filament fed right into the HotEnd, to thick and there may be excessive rubbing to push it in with the extruder and also the related filament course. As well thin and there isn't enough filament fed right into the HotEnd, also thick as well as there might be too much https://sjc1.vultrobjects.com/large-format-printing-services/Fleet-Branding/commercial-printing/exactly-how-to-make-solid-3d-prints-5-ideas-to-enhance-3d-printed.html rubbing to press with the extruder as well as the relevant filament path. Freezing the print as well as the print bed sets everything that makes it less complicated to remove. Avoidance is the best device though, so we do recommend this as a last option or if it is too late and your print is already stuck. Adding an added film between your bed and also the print will certainly ensure that the print will separate removing the finishing with it rather than wrecking the bed surface area.What should I inspect before 3D printing?

You'll additionally notice that when PLA goes bad, it obtains breakable and quickly snaps off.

Recap Of Options: Incorrect Dimensional Accuracy Of A Printed Design

Lower the temperature level and the flow of product will certainly be reduced, leading to under-extrusion. The result of this can be seen in the print, where voids in printed layers can be seen. Additionally, a greater temperature level will result in over-extrusion, so you have to make sure to set a well balanced print temperature to avoid both concerns. A heated bed must be used to ensure great first-layer adhesion. Set the perfect bed temperature after seeking advice from the filament supplier.First Hospital in the U.S. 3D Prints ActivArmor Casts On-site - 3DPrint.com

First Hospital in the U.S. 3D Prints ActivArmor Casts On-site.

Posted: Mon, 09 Jan 2023 14:04:08 GMT [source]

Social Links