November 7, 2023

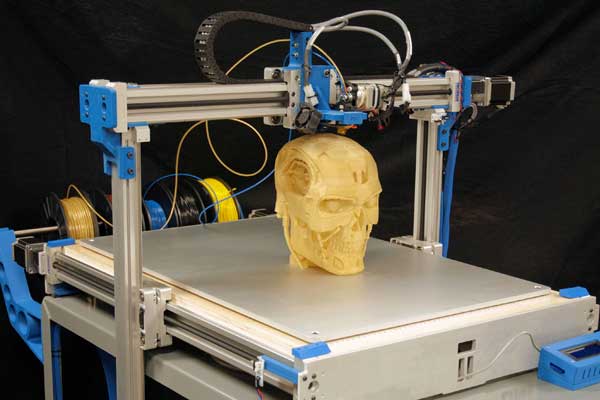

3d Printing Troubleshooting: All Problems & Remedies

Print High Quality Fixing Guide The cost-free activity of the nozzle can be adjusted as well as controlled via the slicer setups. Determine that the nozzle takes the fastest possible path to the next printing point. As a user, you ought to recognize the optimal printing temperatures for the filaments you make use of. This is yet one more typical 3D printer issue that several beginners face. Stringing is a problem that takes place when thin strings of product, comparable to hairs, stay on the surface of a 3D published part, influencing the print's surface area finish.What should I check before 3D printing?

You'll also discover that when PLA goes bad, it gets brittle and also easily snaps off.

Recap Of Remedies: Bendings And Also Strings On Published Information (over-extrusion)

If previous option didn't work, attempt determining the filament size with a collection of calipers. After double checking the results, set the corresponding worth in the used software program application. Generally, ideal prints are made from premium filaments supplied by popular producers. Even though affordable materials may look precisely like the costly ones, they tend to be worse in regards to top quality. The disparity of chemical make-up will certainly once more result in warps as well as misprints.- Stringing at its heart is molten filament oozing out of the nozzle throughout a fast traveling step.

- Enter the layer view while utilizing cutting software application as well as take some time to examine the assistances.

- It usually looks like a percentage of smoke standing for a short time after feeding new filament.

- Under-extrusion is mostly caused by 3 different reasons.

Print Troubleshooting

Also if you pick the very best pattern as well as thickness, the print speed can additionally have an effect on the infill stamina. Infill needs to not be considered as an undesirable enhancement to the print. So, provide it the interest it should have and also print infill like an indispensable part of the design. Stay clear of printing at higher speeds as it can cause bad infill. See to it to blend the material once again in order to also the layers. It is important to modify minimal points with support frameworks, otherwise the print will definitely get warped. It is necessary to supply supports to structures with hard angles and to the acmes of areas that aren't connected with the print body. The complete amount of assistances can be lowered by wisely orienting your print on home plate, so be imaginative. One more service is to give your design with drainage holes, which would certainly make sure that the resin flows through throughout each successive layer change.Unblock A Clogged Up Nozzle

Layer binding problems will certainly additionally emerge as a result of this. In this situation, try increasing the temperature level slightly and also monitoring the outcomes up until suitable layer bonding is attained. A lot of the time, you count on downloaded and install layouts without verifying the design or whether it is printable. It is constantly a good idea to ascertain the generated G-code and sneak peek the model in the slicer software program to make certain that the design can be printed.Velo3D Validates Distributed 3D Printing for Oil and Gas - 3DPrint.com

Velo3D Validates Distributed 3D Printing for Oil and Gas.

Posted: Thu, 26 Jan 2023 08:00:00 GMT [source]

Social Links