November 7, 2023

Print Top Quality Overview

Repairing Overview Sections that are also thin will certainly generate under-extrusions or stop working to obtain grasped and transferred by the drive gear. Parts that are too thick will over-extrude or even obtain stuck someplace along the filament course. High quality filament has a consistent diameter from starting to the end of the spindle. Flexible filaments are challenging to print with most extruders around, as they have a tendency to escape the intended filament course and simply obtain stuck.Will 3D Printed Aircraft Soon Become a Reality? - 3DPrint.com

Will 3D Printed Aircraft Soon Become a Reality?.

Posted: Fri, 03 Mar 2023 08:00:00 GMT [source]

Six Great 3d Printing Fixing Overviews

It resolves the trouble totally as a result of the models perfectly welding to the surface. Support are complex, so your slicer software program will likely provide numerous choices for these structures. The most straightforward means is to stick to the default setups, yet this doesn't constantly make certain that the model's overhangs will certainly be published effectively. It's really important to pick the appropriate kind of the assistance that will certainly maintain your job steady during printing. I 'd recommend taking the PTFE tube out and having an appropriate check out it. After checking out it, you could just need to remove an obstruction, or change the PTFE tube altogether if it's harmed. Below is a photo of Raft in Cura on an XYZ Calibration Dice. You can select a Plethora simply by entering into Cura, scrolling down to Develop Plate Bond in the setups food selection, then choosing Plethora, exact same with a Border. Maintaining your printer in excellent functioning order goes a long way in obtaining the very best outcomes possible.- It decreases exactly how swiftly the model cools off considering that the temperature around the extruded filament is higher.

- Check the rigidness and also correct placement of your printer frame.

- Some extra lines of filament can create your print to look various than it should.

- The initial thing to do if you experience over extrusion is to decrease your printing temperature so filament doesn't flow through so conveniently.

Grasping The Updated Printhead Cover For Epson Xp-15000: An Extensive Guide

If you have poorly set your retraction, either having a high retraction speed or high retraction distance, this can create problems. Even if your printer settings are all at the excellent temperature level, your ambient temperature level can affect your print. If you're publishing in an awesome room, take into consideration putting a cardboard or plastic barrier around the printer to have the required warmth for the very best result. Consistently checking your extruder after each print can prevent this problem. You can inspect your nozzle and recognize carbonized filament develops within, impacting the top quality of your prints gradually.The Coming Commoditization of Metal 3D Printing - 3DPrint.com

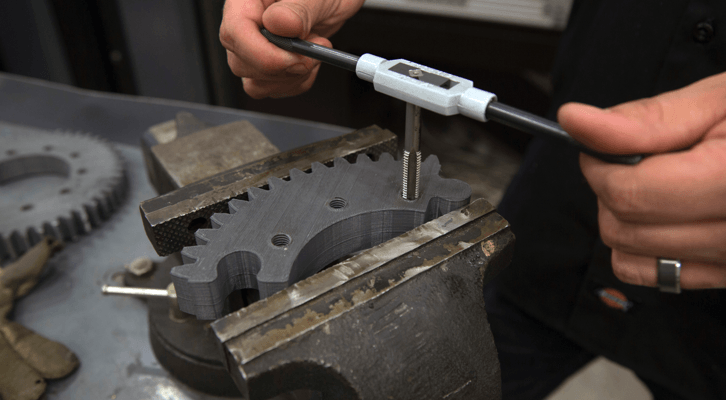

The Coming Commoditization of Metal 3D Printing.

Posted: Thu, 12 Jan 2023 08:00:00 GMT [source]

Just how do you recognize if PLA filament misbehaves?

Social Links