November 22, 2023

7 Most Common Troubles With A 3d Printer Just How To Repair

Print Top Quality Overview In order to fix this, check out different versions that will alter the air flow. Another great suggestion would be to replace the fan or increase it. Under-extrusion is primarily brought on by three various reasons. Your slicing software program may store inappropriate filament data - make sure to repair it, if necessary. The most likely source of the scarcity is improper software application setups. Once more, linking via terminal will offer more control to establish if the BLtouch is functioning properly. The complying with gcode sequence of commands works for repairing. The complying with representation was produced for a video clip guide for the Creality V4 32 little bit mainoards. The remarks are cluttered with individuals who thought the Creality extension impend would certainly match the Creality board, linked the BLtouch incorrectly as well as blew up their mainboard. Never think the extension impend you are using suits the input to the mainboard. If every one of the endstops now come to life, you still may need to tweak the logic as defined above.Ghosting (you Can See The Infill From The Outdoors)

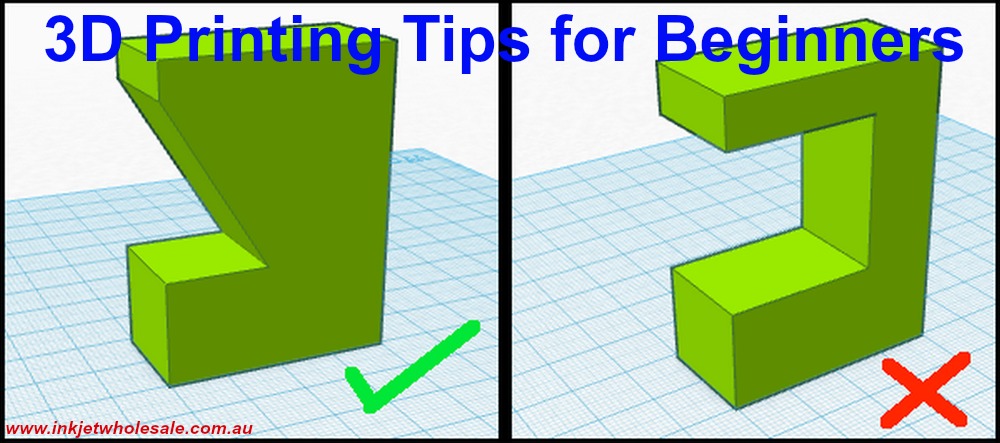

Specifically when switching over from a high temp product to a low temp one, or when cleaning up after fragment filled up filaments. Monitor nozzle temperature while printing, look for high drops in print temperature. Check you're not publishing too near the glass transition temperature of the material. Numerous usual 3D printing problems originate from a poor very first layer. The complying with are the Click here for more info various causes for bed bond to fall short prior to or throughout a print. Parts are contorting off the develop plate or become loosened throughout the prints.- There are certain geometries that are impossible to publish with filament based printers and also throwing assistances at it may not be enough to make it work.

- Make sure you're not weighing down on your bed when leveling it.

- As the print proceeds higher and the warm from the bed decreases the print, prints typically.

Signs Of Leaning Prints:

Sometimes this might happen due to filament size which usually varies. The device will attempt to make use of a larger platform if that's what the configuration reveals, even if the actual one is much smaller sized. Inaccurate selection of the printer in the settings is an additional feasible reason for this problem. You can run into this issue if you try making use of data that are meant for one printer while utilizing one more.Just how do you know if PLA filament is bad?

3D Printing News Unpeeled: Disposable 3D Printed Clay, Insect PLA and Antimicrobial Ferroelectric Composites - 3DPrint.com

3D Printing News Unpeeled: Disposable 3D Printed Clay, Insect PLA and Antimicrobial Ferroelectric Composites.

Posted: Fri, 07 Apr 2023 07:00:00 GMT [source]

Social Links