November 7, 2023

3d Printer Tips As Well As Tricks

Sorts Of 3d Printing In Metal Traditionally, designers and also designers have counted heavily on the manufacturing process to determine the end design. It just took you approximately one month to obtain your finalized concept into the bidding area. NIOSH remains to execute both laboratory and field researches, to identify the risks as well as prospective for employee exposures while using emerging modern technologies such as additive manufacturing.- Yet you can archive styles and save them in your area until you need to edit them once again.

- Bioplotting products consist of PLGA, TCP, collagen and also chitosan, chitosan, collagen-alginate-silica composites coated with HA, soy protein, as well as agarose with gelatin.

- Nanoscale 3D printing-- to put it simply 3D printing of objects that are a simply few billionths of a meter in dimension-- opens outstanding opportunities, the drug store discusses.

- In a number of manufacturing circumstances, 3D-printed parts are currently offering highly dependable choices to conventional replacement components.

- This led to a six-month placement in 2021 in the test kitchen area at the Copenhagen dining establishment Alchemist, which is presently rated 18th on the world's 50 best checklist.

- In 2017, when our individuals responded to exactly how their firms were utilizing 3D printing innovation, the most popular solution was fast prototyping.

New 3d Printing Strategy All Set To Progress Production

3D printers can rapidly produce personalized garments, footwear, precious jewelry, eyeglasses as well as various other fashion accessories. With a 3D check of a person's body, 3D style software application as well as a multi-material 3D printer, one-of-a-kind clothing can be published to exactly fit an individual. 3D published apparel allows generating personalized fashion on-demand and in small sets. In Accrington, Structure for Humanity wishes to place people on the real estate ladder that otherwise would certainly never ever have the ability to afford it. One of the houses has been booked for Mark Harrison, 44, an expert from the community who got a medical discharge from the Military in 2001 after 2 excursions in Bosnia, as well as was later on detected with PTSD. The SHA-256 interaction involves a symmetric key-based bidirectional challenge-and-response authentication system. It is a hand-shaking procedure in which one party presents a secret concern or challenge to an additional celebration.What is the improvement of 3D printing?

Developments in 3D printing have made it easier for developers as well as engineers to personalize projects, produce physical models at various scales, and also produce frameworks that can not be made with more conventional production strategies.

What Is 3d Printing And Also What Is Additive Manufacturing?

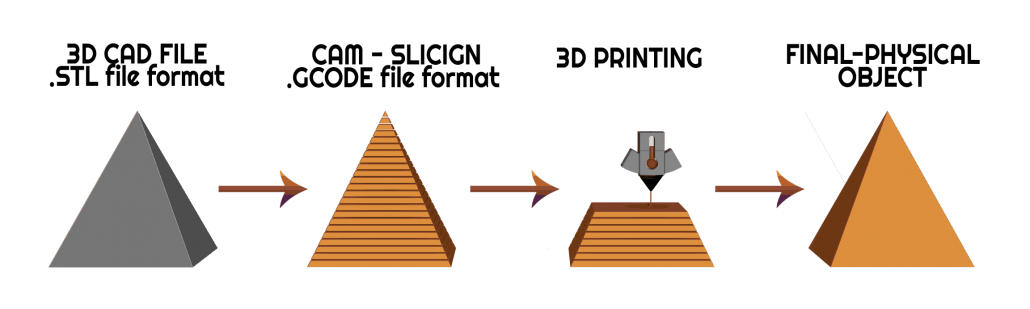

Insurance claims have been made by Behrokh Khoshnevis because 2006 for 3D publishing a home in a day, with additional claims to notionally finish the structure in about 20 hours of "printer" time. A selection of lunar infrastructure aspects have actually been conceived for 3D architectural printing, consisting of landing pads, blast security wall surfaces, roadways, hangars and also gas storage space. In very early 2014, NASA moneyed a little research study at the University of Southern The golden state to better develop the Contour Crafting 3D printing strategy. Lastly, short-term assistance structures need to be incorporated into the CAD design to produce in need of support features (e.g. overhangs, cantilevers). Invented at the Massachusetts Institute of Technology, Three Dimensional Printing makes 3D structures by inkjet printing fluid binder solution onto a powder bed [8-10] A wide variety of materials has actually been made use of in printing because many biomaterials exist in either a strong or fluid state. The procedure begins by spreading a layer of fine powder product uniformly throughout the piston. The X-Y positioning system and the printhead are integrated to print the desired 2D pattern by selective deposition of binder droplets onto the powder layer. The piston, powder bed, as well as part are reduced, and also the following layer of powder is spread.SPEE3D celebrates success in US defense challenge with Cold ... - TCT Magazine

SPEE3D celebrates success in US defense challenge with Cold ....

Posted: Thu, 18 May 2023 07:00:00 GMT [source]

Social Links