November 22, 2023

Current Advancements In 3d Printing Of Biomaterials Journal Of Organic Engineering Full Text

New 3d Printing Technique All Set To Advance Manufacturing But if you're utilizing HP 3D High Reusability TPA made it possible for by Evonik3, then the ended up items will be flexible, light-weight get rid of boosted rebound durability. The only limit really is the resourcefulness of your developers as well as, obviously, your specific style needs. 3D printing functions by converting a 3D version right into a collection of computer-generated instructions to incrementally build up a part layer by layer. Many 3D printing technologies utilize this very same standard property to produce 3D published items. It's a great time to be in the industry, as more materials advancements and procedure controls progress to further automate and ideal 3D printing for usage in thousands more applications. Tooling is required in a selection of production processes, from lost wax tooling for investment spreading to steel tooling for injection molding.Using Ceramic 3D Printing to Achieve Complex Aerospace Structures - 3Dnatives

Using Ceramic 3D Printing to Achieve Complex Aerospace Structures.

Posted: Mon, 15 May 2023 07:00:00 GMT [source]

Cutting-edge - 3d Printer Suppliers & Provider

" The chemical conversion of the material and also all other tests will additionally have to be executed inside the chamber," Momotenko explains. 3D printing is a broad term that consists of a collection of a number of various kinds of 3D printing as reviewed previously. Various other co-authors are from Sungkyunkwan University and Digital Light Innovations.3D Printers Were Never Going To ‘Save’ Manufacturing, But Here’s How They’re Quickly Becoming An Industry 4.0 Staple - Forbes

3D Printers Were Never Going To ‘Save’ Manufacturing, But Here’s How They’re Quickly Becoming An Industry 4.0 Staple.

Posted: Mon, 15 May 2023 07:00:00 GMT [source]

Distributed Manufacturing

The company joined the NASA's 3D Printed Habitat Obstacle in cooperation with the Colorado School of Mines and also was granted a reward for its published structural system model. MX3D Steel established by Loris Jaarman and also group has actually established 2 6 axis robot 3D printing systems, the first makes use of a polycarbonate which is extruded, significantly this system enables the manufacture of freeform non-planar grains. The second is a system that relies upon additive welding the additive welding innovation has been established by different teams in the past. MX3D worked with the fabrication and installation of the metal bridge in Amsterdam for 6 years. The bridge has a span of 12 m and a final mass of 4,500 kg of stainless-steel. In 2017, a job to build a 3D-printed skyscraper in the United Arab Emirates was revealed.What is the strongest 3D printing approach?

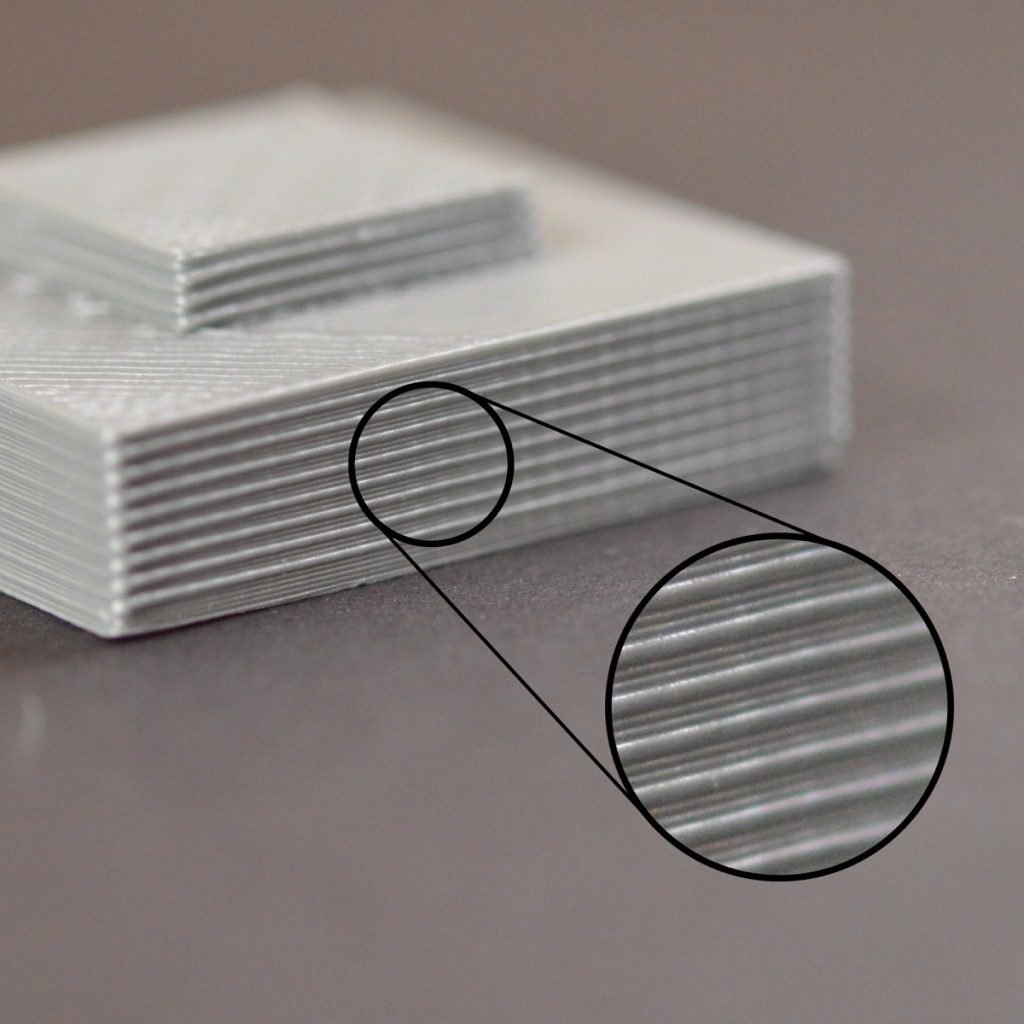

Polycarbonate. According to numerous manufacturers and also customers, polycarbonate (PC) is considered the toughest customer filament around. PC can produce very high-strength parts when printed correctly with an all-metal warm end as well as an unit.

- In this vision of the future, we would certainly come down to breakfast to a newly published croissant or stand out some dough in the machine, touch a few buttons and come back to "homemade" ravioli.

- In the coming years, 3D published components are likely to end up being deeply ingrained within many aircraft, spacecraft and associated high modern technology fields.

- These equipments have mostly all of the same restraints, prices, and also issues as SLM makers, however are used much more heavily in aerospace and clinical applications than anywhere else.

Social Links