November 22, 2023

Protected 3d Printing The Brand-new Disruptive Innovation As Well As Enjoy The Marketplace Expand

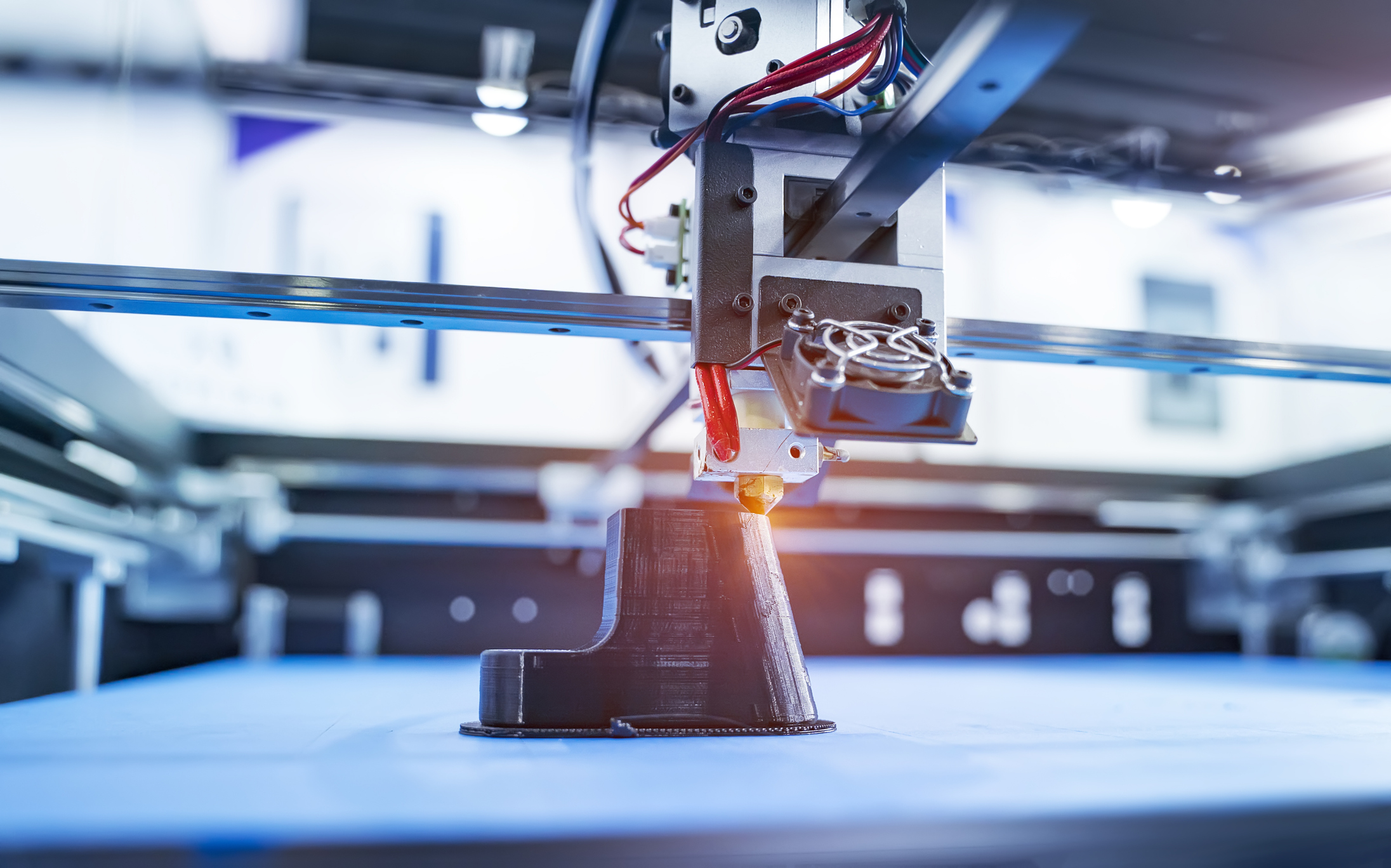

The Supreme Guide To 3d Printing Post-processing Techniques Since then, we have actually come a long way, from human-made to human-and-machine-made. Currently, about three-quarters of study participants are doing their additive manufacturing in-house. It does show up that companies are branching off in their pre- as well as post-processing methods. In 2019, a little over half of participants claimed that they were using machining; currently, almost three-quarters of participant are, dismissing polishing as one of the most popular choice. Thinking about that all handling approaches increased significantly, it may be that companies are experiencing some growing pains and also these obstacles will certainly lessen as companies continue to make this a top priority.What are the 3D printing strategies?

There are numerous sorts of 3D printing, that include: Stereolithography (SHANTY TOWN) Selective Laser Sintering (SLS) Integrated Deposition Modeling (FDM).

Run-down Neighborhood 3d Print

The firm took part in the NASA's 3D Printed Habitat Difficulty in collaboration with the Colorado Institution of Mines and was granted a reward for its published structural system prototype. MX3D Steel established by Loris Jaarman and team has actually developed two 6 axis robot 3D printing systems, the initial utilizes a polycarbonate which is extruded, especially this system permits the construction of freeform non-planar beads. The https://nyc3.digitaloceanspaces.com/custom-printing/Printing-Techniques/graphic-software/anycubic-photon-material-3d-printer-ideas-methods.html second is a system that counts on additive welding the additive welding innovation has actually been developed by numerous groups in the past. MX3D dealt with the manufacture as well as installation of the steel bridge in Amsterdam for six years. The bridge has a span of 12 m as well as a final mass of 4,500 kg of stainless-steel. In 2017, a job to construct a 3D-printed high-rise building in the United Arab Emirates was introduced. 3D printing is a type of printing in the feeling that it incrementally builds a part by beginning at the bottom as well as finishing at the top of the component. Each private layer is functionally 2-dimensional; it only produces an intricate 3D form by printing lots of succeeding layers. One column of this effort is typical, laboratory-based research study to answer essential inquiries as well as solve significant issues for secure additive production.Pointers To Improve Your 3d Printing Skills

" A liquid salt service comes to be a solid metal-- a procedure which we electrochemists can control really successfully," says Momotenko. This very same procedure is used for chrome-plating vehicle components and gold-plating fashion jewelry on a bigger scale. It takes drug store Liaisan Khasanova less than a min to transform an ordinary silica glass tube into a printing nozzle for an extremely special 3D printer. The chemist inserts the capillary tube-- which is simply one millimeter thick-- right into a blue gadget, shuts the flap and also presses a button.- Equally as its name suggests, sheet lamination is a strategy that piles extremely thin sheets of metal over each various other to generate a 3D object.

- With the best methods and products, 3D published mold and mildews make it possible for effective small set production of complex components.

- Style flexibility in 3D printing is taken into consideration "zero-cost" as a result of the layering procedure.

- They demonstrated making use of 3D-printing, bio-inspired designs of cement-based materials is possible as well as unique performance qualities such as flaw-tolerance and also compliance can be achieved.

- Likewise, bioprinting is the construction of hydrogel frameworks with direct unification of cells.

IPFL expands prototyping and production 3D printing capabilities ... - TCT Magazine

IPFL expands prototyping and production 3D printing capabilities ....

Posted: Tue, 23 May 2023 07:00:00 GMT [source]

Social Links