Forklift Batteries Performance in Extreme Temps

Forklift Batteries Performance in Extreme Temps

When it comes to operating forklifts, one of the most crucial components is undoubtedly the battery. But have you ever considered how extreme temperatures affect forklift batteries? Batteries are the lifeblood of these machines, powering them through various tasks and environments.

In this extensive article, we'll explore how environmental factors impact the performance of forklift batteries, focusing specifically on extreme temperatures. We'll dig deep into what happens to batteries in both hot and cold climates, discuss maintenance practices that can extend battery life, and provide insights into how businesses can optimize their operations for better performance. So buckle up; we're about to embark on a thorough journey through the world of forklift batteries!

Understanding Forklift Batteries: Types and Functions

Types of Forklift Batteries

Forklift batteries come in various types, each with unique properties suited for different applications. The most common types include:

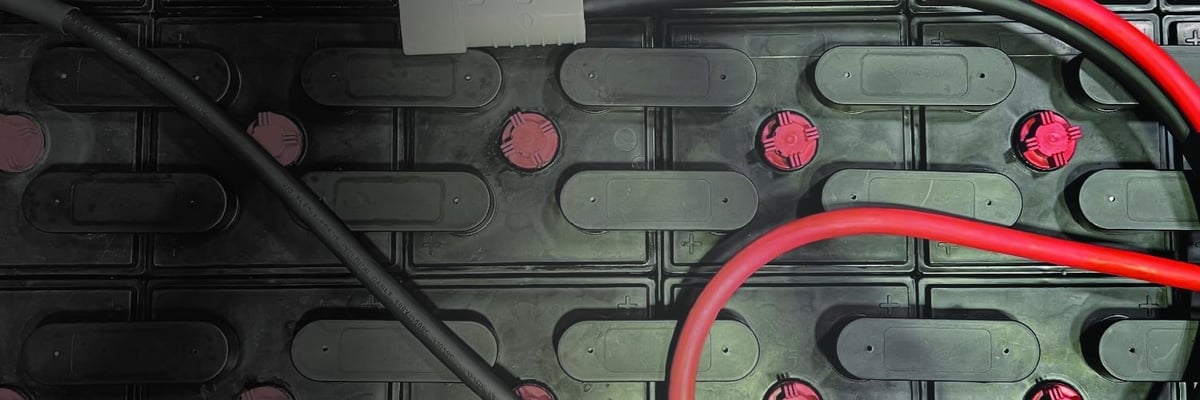

Lead-Acid Batteries: These are the traditional workhorses of the forklift world. They are durable and relatively inexpensive but can be sensitive to temperature fluctuations.

Lithium-Ion Batteries: Gaining popularity due to their longer life span and faster charging times, lithium-ion batteries are less affected by temperature changes compared to lead-acid types.

Nickel-Cadmium (NiCd) Batteries: These are less common but still used in specific applications where high discharge rates are required, although they also suffer performance issues in extreme temps.

Each type of battery has its place, but understanding how they react to temperature extremes is critical for optimal performance.

Key Functions of Forklift Batteries

Forklift batteries serve essential functions:

-

Powering the Motor: They provide energy needed for lifting loads.

-

Supplying Auxiliary Power: Some forklifts use batteries to power additional features such as lights and heating systems.

-

Storing Energy: In regenerative braking systems, excess energy can be stored back into the battery.

Understanding these functions helps us appreciate why maintaining optimal performance is crucial—especially under challenging environmental conditions.

The Science Behind Battery Performance

How Temperature Affects Battery Chemistry

The chemistry within a battery is heavily influenced by temperature. In simple terms:

-

High Temperatures: Lead-acid batteries can experience increased corrosion rates at elevated temperatures, leading to reduced lifespan and efficiency.

-

Low Temperatures: Cold weather slows down chemical reactions within the battery, resulting in diminished capacity and power output.

This interplay between temperature and chemistry underscores why monitoring your forklift's environment is vital for maintaining battery efficacy.

Extreme Heat: Impacts on Forklift Battery Performance

Effects of High Temperatures on Lead-Acid Batteries

High temperatures can wreak havoc on lead-acid forklift batteries. When exposed to heat:

-

Increased Water Loss: The electrolyte solution evaporates more quickly, necessitating more frequent watering.

-

Accelerated Sulfation: Higher temps speed up sulfation—the buildup of lead sulfate crystals—which hampers performance.

-

Thermal Runaway: In severe cases, excessive heat may lead to thermal runaway—a state where increased temperatures cause further degradation of battery components.

Best Practices for Managing Heat Impact

To mitigate adverse effects from heat:

-

Store batteries in shaded areas or climate-controlled spaces whenever possible.

-

Regularly check electrolyte levels and top off with distilled water as needed.

-

Invest in thermal management solutions like cooling systems or insulated enclosures for forklifts operating in hot environments.

Extreme Cold: Challenges Faced by Forklift Batteries

How Cold Temperatures Affect Battery Functionality

Cold weather presents its own set of challenges for forklift batteries:

-

Reduced Capacity: Chemical reactions slow down significantly at low temps, reducing available power by as much as 50% in some cases.

-

Increased Internal Resistance: Cold temperatures increase resistance within a battery; this means less efficiency when drawing power.

-

Risk of Freezing: If electrolyte levels drop too low or if a lead-acid battery isn't charged properly before freezing conditions set in, damage can occur.

Strategies for Operating in Cold Conditions

Here’s how you can keep your forklift running smoothly during chilly months:

-

Use insulated covers or warmers designed specifically for forklift batteries.

-

Keep a close eye on charge levels; ensure they’re fully charged before exposure to cold environments.

-

Consider switching to lithium-ion batteries if your operation frequently encounters extreme cold—they perform much better under those conditions!

Long-Term Effects of Temperature Extremes on Battery Lifespan

Impact on Lead-Acid Battery Lifespan

Frequent exposure to extreme temperatures will inevitably shorten the lifespan of a lead-acid battery. Typically expected to last between 5–7 years under ideal conditions, high or low temps could reduce this significantly—potentially cutting lifespan down by half!

Longevity Factors for Lithium-Ion Batteries

Lithium-ion variants tend to fare better against temperature extremes; however, they’re not immune! With proper care:

They can last 10–15 years even under challenging conditions.

Regular monitoring ensures optimal charging cycles that keep them functioning effectively over time.

Maintenance Tips for Enhancing Forklift Battery Performance

Routine Maintenance Practices

Regular maintenance goes a long way toward ensuring maximum efficiency from your forklift's battery:

-

Conduct monthly inspections focused on fluid levels (especially with lead-acid).

-

Clean terminals regularly to prevent corrosion which affects connectivity and efficiency.

Charging Best Practices

Proper charging techniques also play an essential role:

Avoid overcharging—this degrades lead-acid batteries faster than anything else.

Use smart chargers designed specifically for your type of battery—they automatically adjust charging parameters based on conditions!

Choosing the Right Battery Based on Environmental Conditions

Factors Influencing Your Choice

When selecting a forklift battery suitable for extreme temperatures consider:

By considering these factors upfront you'll make wiser decisions that save money while prolonging equipment life overall!

Monitoring Technology Advancements in Forklift Batteries Performance

Battery Management Systems (BMS)

Modern advancements have made it easier than ever before thanks largely due BMS technology—these systems monitor health metrics ensuring optimal performance no matter what extremes face them!

Working behind-the-scenes these tools provide valuable insights like:

Harnessing software capabilities like predictive analytics help you forecast potential issues before they snowball into costly problems!

**Real-Life Case Studies on Extreme Temperature Effects

Case Study 1: A Warehouse Operating at High Temperatures

A distribution center located in Arizona faced significant challenges when summer temperatures soared above 100°F consistently throughout July-August seasons affecting their fleet's lead-acid forklifts’ efficiency dramatically impacting productivity goals set forth initially leading them reevaluate processes entirely…

Through strategic interventions involving scheduled watering intervals along with investments into climate-controlled storage units allowed them successfully overcome obstacles ultimately boosting operational output substantially!

Case Study 2: Cold Climate Operations

In contrast—a food processing plant situated near Chicago experienced difficulties during winter months where sub-zero temps interfered with lift truck operations due significantly lower capacities observed across all trucks utilized therein…

Their solution included utilizing heated garages combined alongside lithium-ion alternatives yielding remarkable results restoring functionality quickly allowing business continuity without further interruptions experienced previously!

FAQ Section

- Common signs include reduced run time, slower lifting capacity, unusual odors (like sulfur), or physical swelling/bulging around the casing indicating overheating or internal damage.

- Ideally once a week—but during extreme temp months consider doing so more frequently especially if using lead-acid types which require ongoing attention regarding fluid levels maintenance regularly throughout usage periods!

- Yes! Lithium-ion charges efficiently without risk overcharging however always double-check specifications provided by manufacturers before proceeding just ensure safety precautions adhered strictly during operation phases too!

- Absolutely! While initial costs may be higher upfront savings realized through longevity plus reduced maintenance needs outweigh expenses incurred tremendously over time leading ultimately better bottom lines overall profitability margins achieved from operations conducted thereafter successfully maintained continuously thereafter indefinitely onward thereafter too…

- For maximum efficiency aim between 32°F – 77°F ideally however deviations allowed temporarily depending upon specific types used therein across varying situations encountered routinely day-to-day typically expected scenarios arise normally experienced frequently enough…

- Always refer back manufacturer guidelines provided directly alongside technical specifications listed therein ensuring compatibility adherence followed diligently throughout entire process steps involved accurately completed without issue whatsoever occurring unexpectedly later down line subsequently thereafter…

Conclusion

Navigating through extreme temperatures requires vigilance when managing your fleet's forklifts—specifically concerning their precious power sources! By understanding how both heat and cold affect forklift batteries' performances while implementing best practices tailored towards enhancing longevity ultimately safeguards investments made upfront yielding returns seen far beyond expectations originally envisioned when first embarked upon journeys begun initially together collaboratively paving pathways forward proving fruitful rewarding endeavors ultimately leading towards success achieved collectively triumphant together united purposefully striving ahead always aiming higher reaching greater heights fulfilled aspirations accomplished continuously onward relentlessly persevering unwaveringly undeterred resolutely onwards forevermore tirelessly working diligently achieving greatness manifested abundantly flourishing brightly radiantly illuminating future possibilities endless potentialities boundless horizons awaited eagerly embraced warmly wholeheartedly welcomed enthusiastically celebrated joyfully together harmoniously united closely intertwined forevermore…