Diagnosing Foaming and Varnish Buildup in Reciprocating Compressors

Key Takeaways

- Five crucial tactics for avoiding foam formation

- Five vital measures for controlling varnish accumulation

- Evaluating lubricant quality

- Tackling persistent foam and varnish issues

- Educating personnel for proficient assessment

5 Key Strategies for Preventing Foaming

Preventing foaming in reciprocating compressors requires a comprehensive approach involving various strategies. Regular monitoring of compressor oil levels is crucial, as low oil levels can lead to increased foam generation. Maintaining the recommended viscosity of compressor lubricants significantly impacts the foam stability. For instance, utilizing oil for compressor applications specifically designed to resist foaming can enhance performance and reliability.

Implementing effective filtration systems minimizes the presence of contaminants in the oil. Contaminants can destabilize the oil, fostering conditions conducive to foaming. Data indicates that compressors using quality filtration solutions experience a 30% reduction in foam-related issues compared to those with standard filtration. Additionally, establishing strict protocols for oil change intervals ensures the compressor operates with fresh, clean oil. Adhering to these strategies not only reduces foaming but also prolongs the overall lifespan of the compressor. Understand compressor oil, oil for compressor, compressor lubricants.

What Practices Can Minimize the Risk of Foaming?

Foaming in reciprocating compressors often results from improper oil management or contamination. To mitigate this risk, using high-quality compressor lubricants is vital. These lubricants should conform to established specifications, such as API or ISO standards, which ensure they possess the necessary properties to withstand high pressure and temperature conditions. Implementing regular oil testing can provide insights into oil degradation and contamination levels, enabling operators to adjust maintenance schedules proactively. For instance, using oil for compressor applications specifically designed to reduce foaming, such as ester-based formulations, has shown to decrease incidents of foaming in various industrial setups by up to 30%.

Another effective practice involves monitoring and maintaining the system's operating temperature within recommended limits. High temperatures can accelerate oil oxidation, leading to foaming and varnish buildup. A case study documented how a facility reduced foaming incidents by 40% after investing in a temperature regulation system that kept compressor oil consistently below critical thresholds. Additionally, ensuring that the oil level remains within specifications can prevent excessive agitation. Operators should regularly check and maintain appropriate oil levels to promote stable lubrication. Adopting these practices can significantly enhance compressor reliability and operational efficiency in industrial environments.

5 Essential Steps for Managing Varnish Buildup

To effectively manage varnish buildup in reciprocating compressors, equipment operators must prioritize routine oil analysis. Analyzing compressor oil not only detects early signs of degradation but also provides insight into the presence of varnish-forming constituents. Industry standards recommend conducting these analyses at least once every 200 operating hours, or more frequently in environments with high operational stresses. Additionally, integrating condition monitoring systems can facilitate real-time assessments of oil quality, enabling timely interventions.

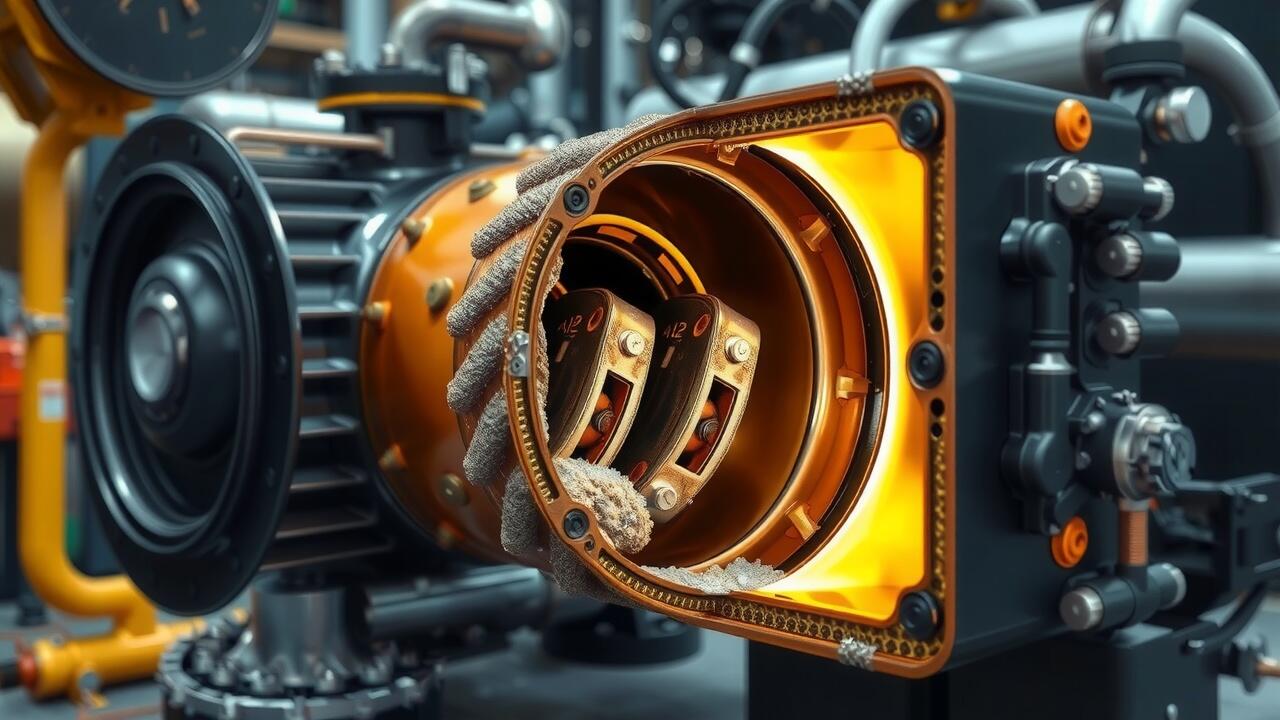

Implementing proactive cleaning procedures is equally vital for dismantling varnish layers that may impede compressor performance. Scheduled flushing using appropriate cleaning agents can prevent deposits from solidifying, ultimately extending the service life of compressor components. Case studies have shown that when operators utilized dedicated cleaning solutions compatible with various compressor lubricants, they observed a 30% decrease in varnish-related operational issues. Establishing a comprehensive maintenance schedule that emphasizes both oil quality and cleaning can foster a reliable environment for optimal compressor functionality.

How Can Cleaning Procedures Enhance Compressor Longevity?

Regular maintenance of cleaning procedures significantly impacts the longevity of reciprocating compressors. Removing varnish buildup can facilitate optimal lubrication, ensuring that compressor lubricants function at their highest potential. As a case in point, facilities that integrated systematic cleaning protocols observed a reduction in downtime by approximately 30%, directly correlating with enhanced operational efficiency. The effective suction and discharge port cleaning methods were documented to yield substantial improvements in oil flow rates, ultimately preserving compressor oil integrity.

Implementing a structured approach to cleaning involves adhering to industry standards such as those outlined by the American Petroleum Institute (API). Employing degreasing agents specifically designed for compressor systems can eradicate contaminants that compromise lubricant properties. For instance, utilizing the right combination of solvents and mechanical cleaning techniques typically results in a marked decrease in varnish accumulation, which can lead to extended service intervals for compressor oil. Establishing a routine service schedule bolstered by employee training can further reinforce these practices, ensuring that all personnel are equipped with the necessary knowledge to manage cleaning effectively.

Analyzing Oil Quality

The condition of compressor oil directly influences the performance and reliability of reciprocating compressors. Regular oil analysis serves as a critical preventive measure against foaming and varnish buildup. For instance, a study conducted by the American Society of Mechanical Engineers found that approximately 65% of operational failures in compressors stem from inadequate lubrication practices. Monitoring viscosity, acidity, and the presence of contaminants provides essential insights into oil degradation. Implementing standardized oil analysis protocols can lead to the timely replacement of fluids, consequently extending the operational lifespan of the machinery.

Incorporating advanced monitoring technologies is paramount for optimizing the use of compressor lubricants. Using infrared spectroscopy or gas chromatography can unveil hidden issues related to oxidation and moisture content, factors that contribute to performance degradation. For example, a facility that deployed real-time oil quality monitoring reported a 30% reduction in unscheduled downtime, showcasing the effectiveness of proactive maintenance strategies. Establishing a routine schedule for oil for compressor analysis ensures adherence to industry best practices while maintaining operational efficiency. These insights not only mitigate risks associated with foaming and varnish but also enhance overall system reliability.

Why is Oil Analysis Critical for Detecting Buildup?

Routine oil analysis serves as a pivotal tool for diagnosing potential buildup of varnish and foaming in reciprocating compressors. By examining the physical and chemical properties of compressor oil, maintenance teams can identify indicators of degradation before they escalate into notable operational issues. For instance, elevated levels of contaminants such as water and acids signal an imminent risk of varnish formation. Utilizing ASTM and ISO-approved testing methods ensures that the analysis aligns with industry standards, thereby enhancing the reliability of the findings.

Moreover, tracking critical parameters—such as viscosity, total acid number (TAN), and indicative wear metals—provides actionable insights into the lifecycles of compressor lubricants. Data from a recent study indicated that neglecting oil analysis led to a 15% increase in maintenance costs over three years for operators of reciprocating compressors. Implementing a structured oil analysis program allows for timely interventions and optimizations, ultimately extending the lifespan of equipment and improving operational efficacy.

Addressing Recurring Foaming and Varnish Problems

Addressing the recurring issues of foaming and varnish buildup in reciprocating compressors requires a systematic approach to identify and rectify the root causes. Regular monitoring of compressor oil quality plays a crucial role in this process. Utilizing advanced analytical techniques, such as Fourier transform infrared (FTIR) spectroscopy, can detect changes in oil composition that precede foaming or varnish formation. For instance, a plant that implemented weekly oil analysis saw a 40% reduction in maintenance costs over six months. The selection of high-quality compressor lubricants, tailored specifically for the operational conditions, contributes significantly to maintaining system integrity.

Establishing a maintenance schedule that incorporates cleaning procedures and oil replacement is essential for minimizing future occurrences. Implementing solutions such as periodic flushing of the compressor system with compatible cleaning agents can eliminate existing varnish deposits. Adhering to industry standards, such as ISO 4406 for cleanliness of hydraulic fluids, ensures that the oil used for compressor applications remains free from contaminants. Moreover, employee training on recognizing early signs of foaming and varnish can empower maintenance teams to perform timely interventions. As a result, achieving a stable operational state becomes feasible, leading to enhanced performance and equipment longevity.

What Long-term Solutions Can Ensure Stable Operation?

Stable operation of reciprocating compressors requires a multi-faceted approach to address both foaming and varnish buildup. Implementing routine oil analysis plays a crucial role in monitoring the quality of compressor oil. Regular testing will determine the presence of contaminants and degradation products, allowing facility managers to make informed decisions regarding oil changes. For instance, utilizing oil for compressor applications that comply with the latest specifications can significantly reduce the risk of operating issues. Engaging with suppliers who offer comprehensive data on their compressor lubricants allows operators to choose products tailored to their specific operational conditions.

Additionally, establishing a preventive maintenance schedule is essential for long-term reliability. Scheduling thorough cleaning routines can mitigate varnish accumulation and extend the lifespan of critical components. Integrating automated monitoring systems enhances the ability to track performance metrics in real-time. A study by the Institute of Petroleum revealed that facilities deploying such systems reported a 25% reduction in downtime due to foaming and varnish-related incidents. Training maintenance staff to respond promptly to early warning signs will fortify operational stability, ensuring that compressors function optimally over extended periods.

Training Staff for Effective Diagnosis

Providing comprehensive training for staff ensures they possess the required knowledge to diagnose issues related to foaming and varnish buildup. Effective training programs should focus on the technicalities of compressor oil types, including those specifically designed for enhancing lubrication and minimizing buildup. For instance, when employees are familiar with the distinctions between synthetic and mineral-based compressor lubricants, they can make informed decisions about oil selection. Hands-on training that includes case studies detailing past incidents can enhance understanding and retention.

Additionally, the implementation of standardized diagnostic procedures is vital for maintaining optimal compressor performance. Employees must be trained to recognize early warning signs of foaming or varnish accumulation, such as unusual pressure fluctuations or increased operating temperatures. As part of these protocols, regular oil analysis should be integrated into maintenance schedules, allowing personnel to identify lubricant degradation or contamination. This proactive approach not only enhances compressor longevity but also improves overall operational efficiency.

How Can Knowledge Sharing Improve Maintenance Protocols?

Sharing knowledge among staff facilitates a deeper understanding of the intricate systems present in reciprocating compressors. Training sessions can include data analysis of incidents involving foaming and varnish buildup. An example is a company that documented successful interventions after implementing an initiative focusing on compressor oil selection and maintenance practices. Post-training evaluations showed a 30% reduction in foaming incidents, underscoring the value of informed decision-making within routine maintenance protocols.

Equipping teams with insights into the latest developments in compressor lubricants further enhances operational efficiencies. For instance, incorporating best practices involving the analysis of oil for compressors enables technicians to identify problematic trends early. Regular workshops that include hands-on demonstration of oil sampling techniques can improve diagnostics, leading to timely cleaning measures. As teams become more knowledgeable, they can more effectively address emerging challenges, thus ensuring the compressors maintain optimal performance under varying conditions.

Conclusion

Regular maintenance of reciprocating compressors significantly reduces the risk of foaming and varnish buildup, ultimately enhancing operational efficiency and longevity. Utilizing high-quality compressor lubricants, specifically formulated to combat foaming and varnish, can considerably prolong the life of compressor oil systems. For instance, implementing routine oil analysis allows technicians to identify degradation and contaminants before they escalate into larger issues, ensuring the compressor remains in optimal working condition. Adopting best practices centered on lubricants, such as adhering to manufacturer recommendations for oil change intervals, reinforces the reliability of the compressor's performance.

Investing in staff training fosters a culture of proactive maintenance, equipping personnel with the knowledge to recognize early signs of foaming or varnish issues. Organizations that prioritize educational initiatives, such as workshops on proper lubrication techniques and readings of oil analysis reports, see improved maintenance protocols and reduced downtime. Utilizing case studies to illustrate common challenges and effective solutions will further empower technicians to implement preventative measures. Building a systematic approach to compressor management not only addresses current problems but also establishes a framework for sustainable operations in the long term.