November 7, 2023

3d Printing Modern Technologies: Types And Benefits

3d Printer Pointers As Well As Methods Discover the current commercial upkeep best methods, trends as well as information from ATS and also gain from market specialists and also leading makers. 3D printed film prop Starbug Red Dwarf is a British funny franchise business which extends over 11 series of a television sci-fi comedy since 1988. Concrete spreading with sand mold and mildews Additive production regularly opens brand-new application areas in design. HSS Material Network-- Evidence of Idea TPU Launhardt The HSS Material Network has released a new evidence of principle.What is the development of 3D printing?

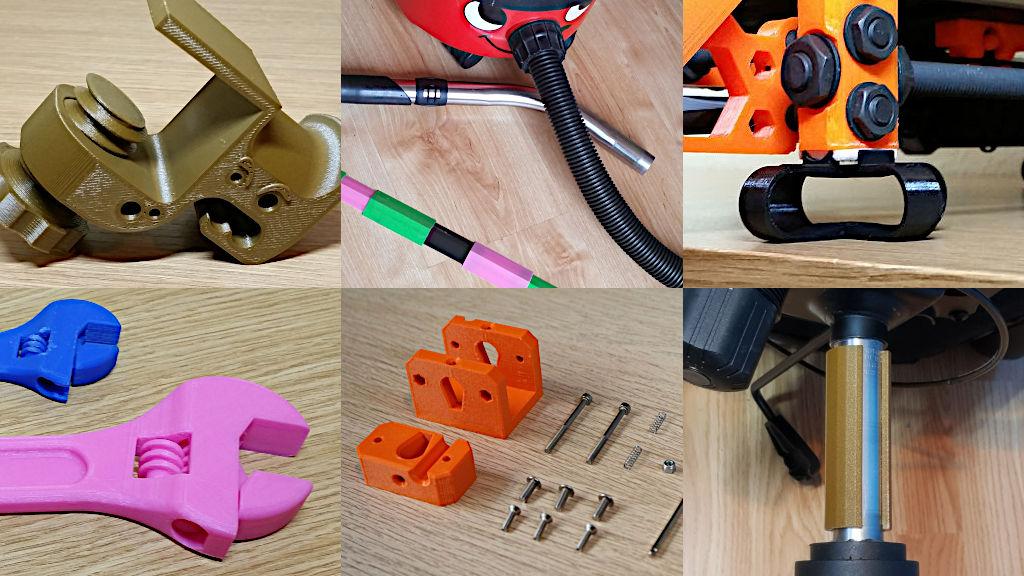

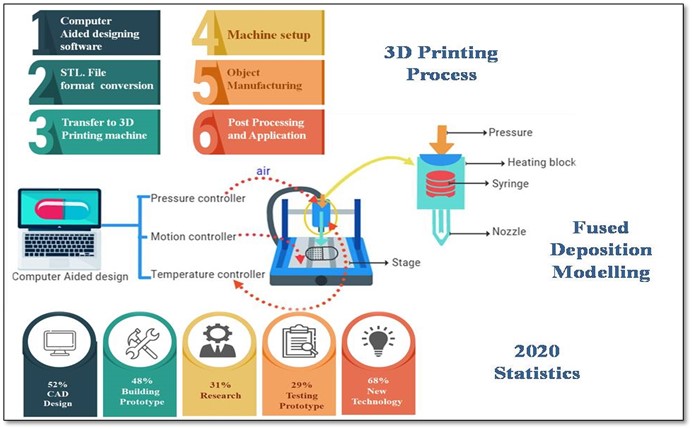

Developments in 3D printing have actually made it simpler for developers and engineers to customize projects, develop physical prototypes at various scales, as well as produce structures that can not be made with more traditional manufacturing techniques.

Publishing Solutions

Cartridge computes a SHA-256 message authentication code utilizing its ROM ID, secret, the arbitrary challenge got, and a few other information aspects. Instantly after a cartridge is set up into a protected 3D printer, the adhering to series of occasions happen. What are your essential aspects when picking an Click for info outsourcing partner for 3D printing? Momotenko specializes in electro-plating, a branch of electrochemistry where steel ions put on hold in a salt option are brought right into call with a negatively billed electrode. The favorably billed ions incorporate with electrons to create neutral steel atoms which are transferred on the electrode, developing a strong layer. Moreover, several other types are also in research that additional enhance the application as well as the flexibility of this technique.$99,000 to build a house? Win $1M in Icon's affordable housing ... - Austin American-Statesman

$99,000 to build a house? Win $1M in Icon's affordable housing ....

Posted: Wed, 15 Mar 2023 07:00:00 GMT [source]

Wish To Learn More? Sign Up For E-mails On The Current News On Additive Production

This approach is time-consuming and labor-intensive but can substantially boost the surface high quality of FDM printed components. Dimensional accuracy is an essential problem in 3D printing, particularly for components that have to fit exactly with other parts. Due to factors like material shrinking as well as nozzle diameter, printed parts may not satisfy the wanted dimensional requirements or fall within an acceptable resistance range.Navy Must Go All In on Additive Manufacturing, Official Says - National Defense Magazine

Navy Must Go All In on Additive Manufacturing, Official Says.

Posted: Fri, 17 Mar 2023 07:00:00 GMT [source]

Use Situations For 3d Printing Are Escalating

Several intended deep space objectives will certainly make use of significant components produced on 3D printers. By publishing on demand precede, long period of time missions can get more freedom from Earth as well as optimize their styles for zero-gravity environments. Steel 3D printing supplies aerospace companies an affordable advantage through new levels of layout optimization, part assimilation and also reduced expenses.- Specifically, job done in the last 5 years will certainly be highlighted to show the development of the field.

- He wants to use his printing technique to generate metal frameworks that allow for a more targeted control of chain reactions than feasible thus far.

- 3D printing an end product in just one to 2 days is practical with multiple 3D printing innovations, such as Laser Sintering, Fused Deposition Modeling and Direct Metal Laser Sintering.

- Due to its speed and scalability, it might be the technology that drives metal additive production capacities into production quantities.

Social Links