November 7, 2023

3d Printing Patterns: 6 Significant Growths

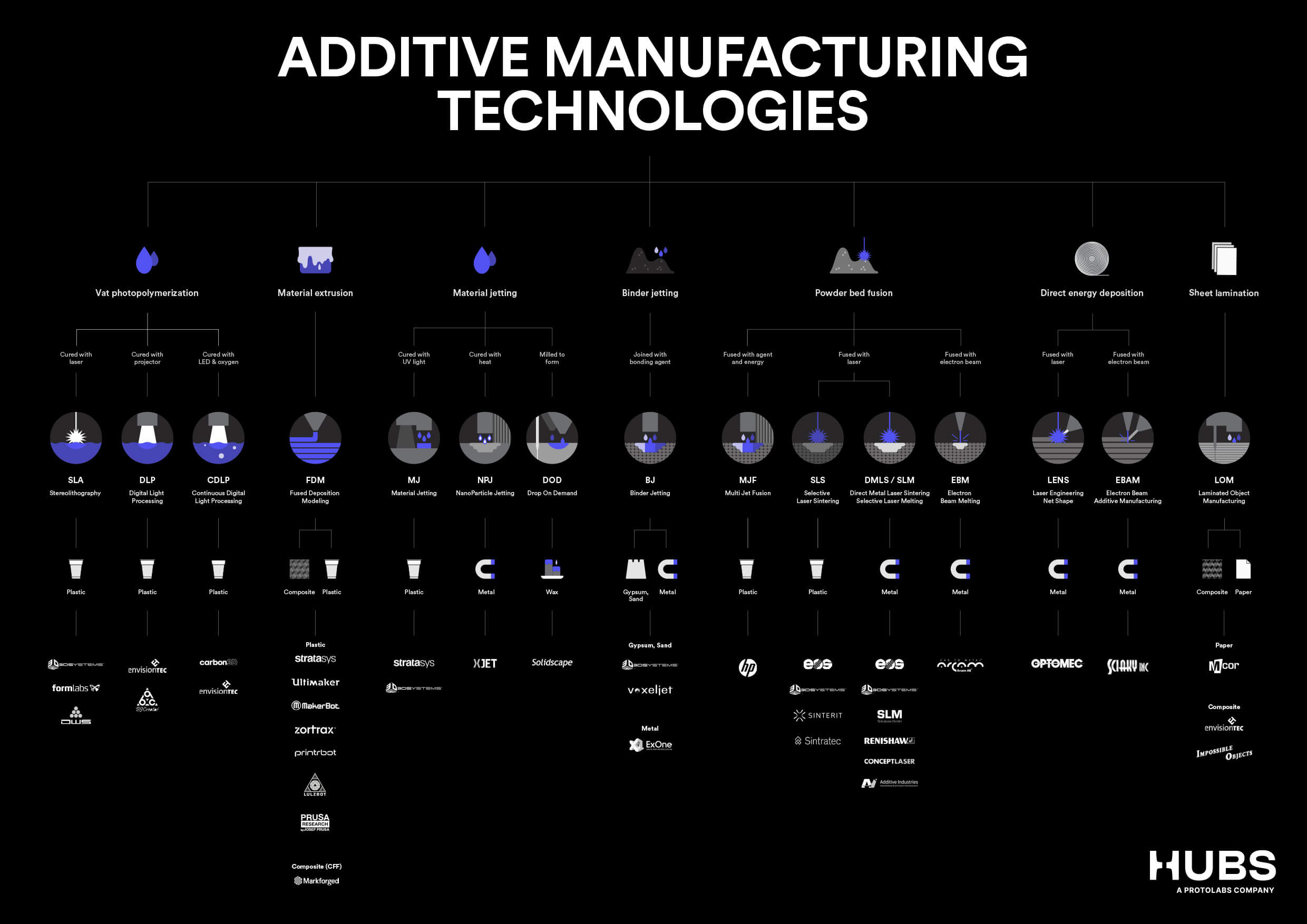

Industrial 3d Printing & 3d Printer Supplier Warm therapy processes, such as annealing, solidifying, or tempering, can be put on change the inner structure of the steel, causing improved stamina, ductility, or durability, depending upon the details demands of the component. Chemical smoothing is an advanced post-processing strategy that can be utilized to boost the surface area finish of FDM printed components, specifically those made from abdominal plastic. This method includes exposing the part to a chemical-- acetone, when it comes to ABS-- which partly liquifies the surface layer of the plastic, properly raveling layer lines and surface blemishes. It is important to use proper safety and security precautions and also ventilation when working with chemicals like acetone. Different 3D printing technologies have distinctive qualities that need certain post-processing methods.Which technologies are presently used in 3D printing?

- Product Extrusion.Fused Deposition

- Modeling( FDM) 3D Bioprinting.Construction 3D Printing.Vat Polymerization.Stereolithography (RUN-DOWN NEIGHBORHOOD)

- Digital Light Processing( DLP) Liquid Crystal Show( LCD)

Vast Array Of Shanty Town Materials

Additionally, materials such as solvents may send out volatile natural substances, as well as some processes may promote discharge of volatile natural substances. Although the first steps have been made almost three years back, 3D building and construction printing has actually struggled to connect for many years. The first innovations to attain some media attention were Contour Crafting and also D-Shape, with a few erratic articles in 2008-- 2012 and a 2012 television report. D-Shape has additionally been featured in an independent documentary devoted to its maker Enrico Dini, called "The guy that publishes houses". But this does not constantly happen, especially if the piece climbs also quickly or the material is particularly thick. With this brand-new method, called shot CLIP, or iCLIP, the researchers have placed syringe pumps on top of the increasing system to add additional material at bottom lines. Among the primary benefits of cold welding is its ability to sign up with components without the requirement for heat, which can be helpful for applications where thermal stress or distortion could jeopardize the honesty of the 3D published components. Furthermore, cold welding can be executed in different atmospheres, including vacuum or inert gas ambiences, making it appropriate for specialized applications like aerospace as well as microelectronics. Before the hydrographic process begins, the 3D printed part should be correctly prepared. First, the component is fined sand to attain a smooth surface, then primed and repainted with a base coat.Selective Laser Sintering (sls)

The ability to 3D print practical electronics systems will open up many opportunities for smart parts as well as items. With Binder Jetting 3D printing technology, and also the tool-free production of mold and mildews and also cores for classic steel spreading procedures, we are opening up brand-new perspectives for the foundry sector. With no limitations on individualization, light-weight building and construction and also demanding or complicated geometries. And not to forget with a terrific prospective for price optimization in the production process. Voxeljet likewise uses additive manufacturing worldwide as an on-demand solution.- For example, cord EDM is fit for removing supports from elaborate geometries, while CNC milling is better for components that need high dimensional precision.

- In cold welding, the surface areas to be signed up with are very first prepared by getting rid of any type of surface pollutants, such as oxides or residual fragments from the 3D printing process.

- Several companies are currently providing 3D printed clothes and footwear as retail products.

Prominent 3d Printing Post-processing Methods

Advanced post-processing techniques, such as hydrographics, chilly welding, as well as electroforming, are utilized to develop elaborate styles, sign up with components, and down payment steel layers onto 3D printed components. These sophisticated techniques offer high precision, improved surface area high quality, and also the ability to develop complex geometries, making them appropriate for applications in various industries. Selective Laser Sintering is a 3D printing technology that makes use of a high-powered laser to uniquely fuse powdered material such as nylon, layer by layer. SLS printed parts show high strength and toughness, making them suitable for functional applications.Metso, a renowned industry leader, has recently secured substantial ... - SteelGuru

Metso, a renowned industry leader, has recently secured substantial ....

Posted: Fri, 09 Jun 2023 02:31:54 GMT [source]

Social Links