November 7, 2023

7 Most Typical Troubles With A 3d Printer How To Repair

7 Most Usual Troubles With A 3d Printer Exactly How To Fix Try raising this and also note the result (too much as well as you will likely see the infill pattern poking through the object's noticeable wall surfaces and other such surfaces). If your slicer sustains it, established a minimum time per layer to ensure proper air conditioning. This generally causes the slicer dynamically reducing the print speed to make sure the minimal layer time, which, in this certain instance, won't help all that much. Particularly when switching to smaller nozzle sizes your extrusion settings require to be area on. The smaller sized diameter openings are way less flexible as we're facing greater stress trying to extrude through a smaller opening to start with. You're seeing gaps appear in the corners produced in between the outer shell and also the infill's diagonal lines. You're seeing an infill that appears slim, weak or unequal. It might avoid or tear and have open openings without any infill present. The lines on the within are usually not as thick as the outlines or covering surface. These ugly-looking flaps are covering the print, accompanied by a number of warped offsets that were definitely not designed to be there.Signs Of Bad Surface Area Quality Above Assistances:

Specifically when switching over from a high temp material to a reduced temp one, or when tidying up after fragment filled filaments. Display nozzle temperature level while printing, check for high drops in print temperature. Check you're not printing too close to the glass change temperature of the material. Many common 3D printing issues come from an inadequate first layer. The following are the numerous causes for bed adhesion to fail before or throughout a print. Parts are deforming off the develop plate or end up being loosened throughout the prints.- There are specific geometries that are difficult to print with filament based printers as well as throwing supports at it may not be enough to make it work.

- Make certain you're not weighing down on your bed when leveling it.

- As the print proceeds greater and also the warmth from the bed lessens the print, prints usually.

- Experienced users must be familiar with Acceleration and also Jerk-- these setups let you tailor the rate of the head when altering instructions during the manufacturing.

Avoiding Steps, Mechanical

Having also few can create them to sag down into the hollow area and also endanger the integrity of your print. The solid layers need to be at the very least 0.5 mm thick for a strong foundation. If you're publishing at a layer elevation of 0.1 https://sjc1.vultrobjects.com/large-format-printing-services/Fleet-Branding/customization-trends/best-3d-printing-product-filament-for.html mm, print five solid layers prior to enabling the hollow infill. You may also see spaces in each published area past the spaces between separate layers.Exactly how do you understand if PLA filament is bad?

Layers Not Lining Up Well

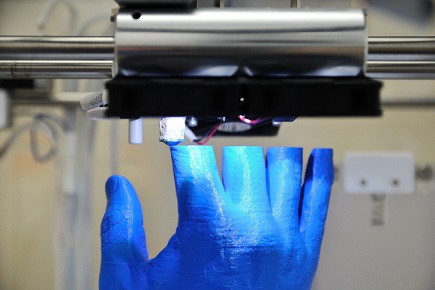

Get rid of any possible resource of friction such as misaligned poles or sloppily hanged belts, because they will certainly disrupt the printing process. Non-manifold geometry can be neatly dealt with in expert 3D-creation suites like Blender or food processor or Meshmixer. Thanks to its integrated functions, the software program will certainly lay out the weak points of your version and permit to repair it before the cutting process starts.First Hospital in the U.S. 3D Prints ActivArmor Casts On-site - 3DPrint.com

First Hospital in the U.S. 3D Prints ActivArmor Casts On-site.

Posted: Mon, 09 Jan 2023 14:04:08 GMT [source]

Social Links