November 7, 2023

Recent Advances In 3d Printing Of Biomaterials Journal Of Biological Engineering Full Message

Types Of 3d Printers And Also Totally Free Cad Software Program For 3d Printing Secret components for facilities, energy production, water systems, healthcare and also various other important services can be printed on-site as required to keep continuity. • Extra parts-- When machines require outdated or unusual extra components, 3D publishing the required components locally prevents downtime waiting on substitutes to show up. Digital scans as well as layouts of tradition components can be dispersed anywhere in the world for on-demand manufacturing. Recent developments in biofactor printing innovation allow the simultaneous printing of pharmaceutical and Get more info also biological agents during manufacture.What are the 3D printing strategies?

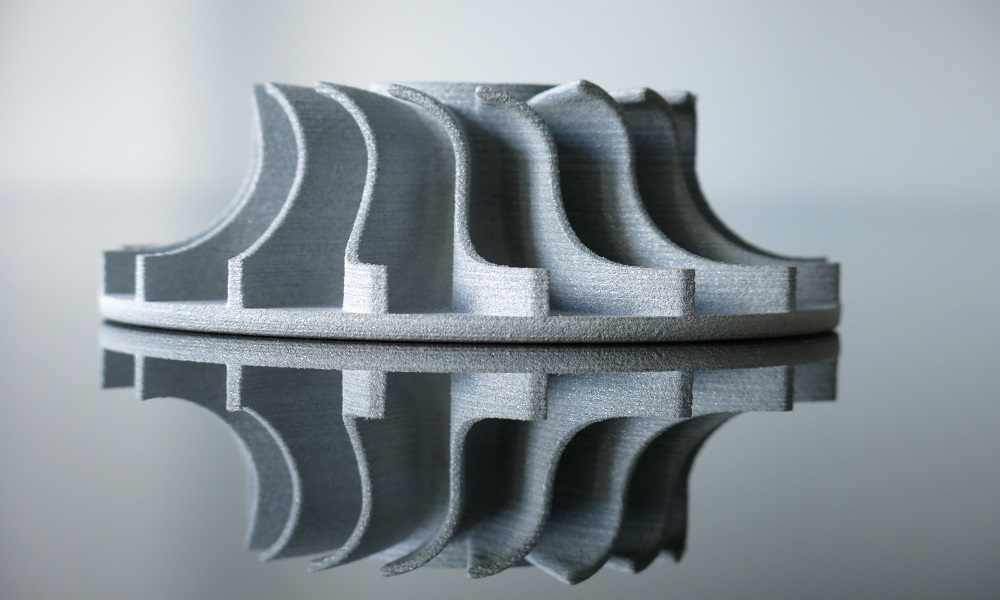

There are several types of 3D printing, which include: Stereolithography (SLA) Selective Laser Sintering (SLS) Merged Deposition Modeling (FDM).

Powder Ded

LOM is rapid as well as ideal for making big prints yet the surface area coating is harsh. Although macro and also microarchitecture has made great strides in the past 5 years, added work must concentrate on the nanoarchitecture (e.g. biochemical particles). Due to extreme processing problems of SFF techniques (e.g. warmth, organic solvent), biochemical molecules are not typically incorporated straight right into the scaffold. Developments have been made to synthesize new macromers with biodegradable moieties, nevertheless, these products have not been FDA approved. FDM, SLS, and 3DP have the ability to make use of polymers such as PLGA, PLLA, and also PCL without chemical modification which will certainly aid accelerate future FDA approval for biomedical gadgets. In bioprinting, little rounds of bioink composed of cells as well as hydrogel materials (e.g. alginate or decellularized extracellular matrix) are published in a desired form.Additive 3d Printing With Voxeljet Makes Sure Competitive Advantages - Practically And Also Financially

This approach is taxing and labor-intensive but can substantially boost the surface area quality of FDM printed components. Dimensional precision is an important worry in 3D printing, specifically for parts that must fit precisely with other components. As a result of elements like material shrinkage as well as nozzle size, printed parts may not fulfill the desired dimensional requirements or drop within an appropriate resistance range.nScrypt 3D printed electronics see significant improvement from new ... - 3D Printing Industry

nScrypt 3D printed electronics see significant improvement from new ....

Posted: Tue, 04 Apr 2023 07:00:00 GMT [source]

Exactly How 3d Published Latticework Frameworks Improve Mechanical Residential Properties

Potential applications of this modern technology include constructing lunar structures of a material that could contain approximately 90-percent lunar product with only ten percent of the material requiring transportation from Earth. XtreeE has actually established a multi-component printing system, placed on top of a 6-axis robotic arm. The growth of distributed 3D printing depends on additional technological renovations to broaden the series of printable products, boost part sizes, facilitate multi-material printing and provide higher dependability at reduced costs. As printers boost and also become extensively offered, electronic layouts for fabricating lots of helpful products will certainly spread out between areas with on the internet libraries and markets. Dispersed 3D printing can eventually change economic situations and also standards of living in linked cultures around the globe. • Redundancy and also protection-- A network of distributed 3D printing centers develops neighborhood ability for manufacture of essential components, making sure supply chain safety as well as disaster preparedness.- These tensions can jeopardize the part's mechanical properties, making it a lot more susceptible to bending, splitting, or failure under tons.

- Khoshnevis recognized that this strategy might surpass these techniques where "existing approaches are restricted to construction of part measurements that are typically less than one meter in each measurement".

- 3D bioprinted body organs could one day fix body organ benefactor scarcities and also reinvent medical treatments.

- Explore various filaments as well as 3D printer settings to enhance your prints over each version.

- Consequently, 3D printing is emerging promptly,2 the inspiration for an extreme shift from quick prototyping to fast manufacturing.

- To plan for the medical separation of conjoined twin ladies in 2020, cosmetic surgeons at the University of Michigan C.S. Mott Kid's Health center needed practical, life-size versions of their individuals' common body organs.

Social Links