November 7, 2023

Leading Ten Ideas When Getting Going With 3d Printing

Mastering The First Layer: 5 Pointers For Best 3d Prints It has a big tensile stamina making it ideal for making architectural parts. While strong, you can also reinforce PLA 3D prints utilizing the methods highlighted above. Usual methods of reinforcing the 3D prints include applying epoxy, annealing, or electroplating. To accelerate things, you have to choose a simple pattern with few non-extrusion movements and minimal switches. If you're not also interested in visual appeals yet want to speed up the printing procedure, choosing a lower resolution can assist you print quicker. A slicer is a sort of software developed to transform CAD data into a style that your printer can read as well as comprehend. Three-dimensional printing can be tiresome, specifically if you make use of an FDM printer. The melting, extruding, and also air conditioning of filament takes time, and also you might wonder what are the mysteries of fast prototyping.North Bay teen's 3D printing project could soon save lives - CBS News

North Bay teen's 3D printing project could soon save lives.

Posted: Mon, 10 Apr 2023 07:00:00 GMT [source]

Print In Batches

As we pointed out earlier, CAD is still a critical part of the 3D printing process as well as, as a CAD user, you may value some software that can save you time in that sector as well. Assume seriously about which elements of your style requirement to be 3D printed. Some functions could be executed a lot more successfully with other manufacturing methods. When proper, incorporate other components right into your layout to minimize print time and also cost or to improve important attributes. Below are a few instances of where straightforward hardware integrations or style modifications can boost component success. PLA is just one of the most frequently used materials in 3D printing.- If it is too hot, there will be filament strings between spaced components.

- If you need to know a lot more, take a look at my guide on Exactly how To Resolve Ghosting in 3D Printing for an in-depth evaluation.

- Commonly, an infill of concerning 25% is optimal for the majority of tasks, but you might have the ability to exercise with much less or boost the thickness to suit the needs of a practical component.

- There is a compromise to obtain top quality with 3D prints however, since lowering the layer elevation or enhancing print resolution also increases the variety of layers of your print

- The result was a shape that imported perfectly right into Lightwave to create a perfect shape.

- While this is only real for FDM approaches, similar resolution settings and also concerns will still appear with other 3D printing techniques.

Use Pla Filament

While a smaller sized printing nozzle (0.4 mm), the influence this will have on your print is extra complicated. When reserved for premium research study, the evolution of 3D printing now encapsulates every little thing from fast prototyping to full-scale manufacturing. You can talk with our highly-qualified Job Engineers as you reveal the https://large-format-printers.b-cdn.net/Printing-Glossary/large-format-printing/print-high-quality-fixing.html appropriate innovation for your product, or do some study on your own by visiting our site. General and nuanced info concerning the globe of 3D printing can be located in our whitepapers, case studies, infographics, blog and also other resources.Expertise in 3D printing — and a little sabotage — reveal new ... - Argonne National Laboratory

Expertise in 3D printing — and a little sabotage — reveal new ....

Posted: Wed, 12 Apr 2023 07:00:00 GMT [source]

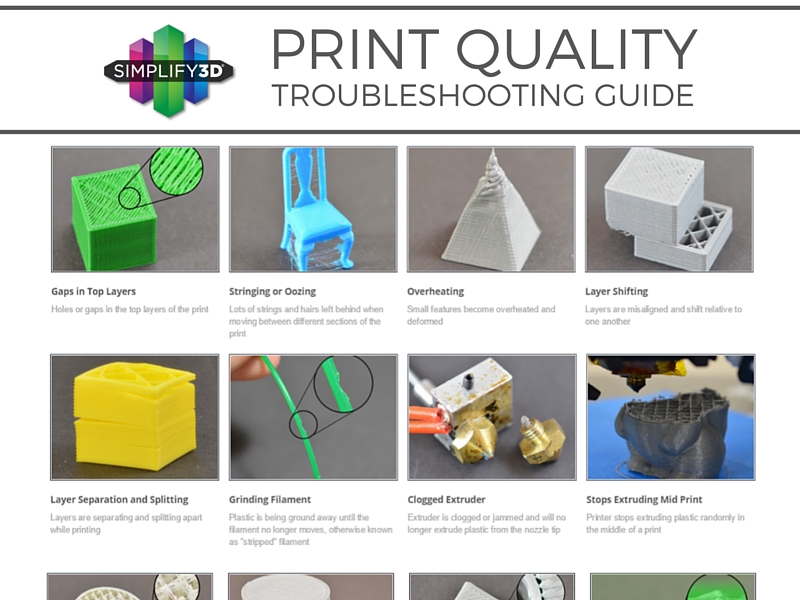

Finest 3d Printing Troubleshooting Guide To Deal With 10 Typical 3d Printer Problems

Normally, this has to do with 10 mm/s to 20 mm/s 2nd lower than the speed for the internal wall surface. If the internal wall surface rate is readied to 40 mm/s, 25 mm/s need to function best. However, for smaller sized models, you can additionally set it to ~ 30 mm/s to keep the rate distinction as reduced as feasible. Try a few worths until you find the one which provides good assistance for the design, however likewise break away quickly when it's time to remove them. Cooling is likewise one more bottom line to keep in mind when trying to obtain excellent prints.How can I make my 3D prints much better top quality?

Social Links