November 22, 2023

Mastering The Very First Layer: 5 Tips For Excellent 3d Prints

3d Printing Pointers + Much Easier Cad As an example, PLA functions best under the activity of a solid air conditioning follower. As a result, you must reduce the cooling price based on the material you are working with. According to Cura, a preferred slicer, you can enhance your 3D prints by readjusting the line size to an also several of the layer elevation. There was no way I can print the details for the plane. However when I was placing my first print with each other, it reminded me of building version aircrafts when I was a child. A little study showed me that the model train globe and also the R/C group does this all the time. So I purchased some transparent decal sheets that I can go through my inkjet printer. They showed up a few days later and it worked perfectly. A common mistaken belief concerning 3D printing is that the procedure is similar or the exact same across different equipments and also innovations. The fact is that 3D printing includes a selection of innovations with distinct layout considerations. Many 3D printing tasks can take a long while to end up.Decrease Cooling

It's much better to over-inform than under, due to the fact that possibly that one setup that appears worthless to you is really the whole reason your 3D print isn't appearing right. The temperature reported by the thermistor from a printer's hotend is not as accurate as you could anticipate. In some cases, the real temperature level inside the heatblock can range in between 10C to 15C from the one reported by the thermistor. Besides that, using nozzles with different materials can affect the temperature level you require to make use of for some filaments.- If you wish to know extra, have a look at my overview on Just how To Fix Ghosting in 3D Printing for an extensive evaluation.

- Usually, an infill of concerning 25% is optimal for the majority of jobs, but you might be able to work out with less or enhance the density to match the needs of a practical component.

- There is a trade-off to get good quality with 3D prints however, considering that decreasing the layer elevation or boosting print resolution additionally raises the variety of layers of your print

- The outcome was a shape that imported flawlessly right into Lightwave to develop a perfect form.

- While this is just true for FDM techniques, similar resolution setups and also issues will certainly still show up with various other 3D printing approaches.

Commercial Composite 3d Printers

They have updated the device and it just prints ALL DAY AND ALSO EVENING LONG. Yes, it is a clone of Replicator from when it was an open source maker. Yet they have improved on the initial open source layout and also made it their own. With a twin extrusion printer, you can combine a typical material with support products. By publishing assistances with a various product, quickly remove or liquify them from the last print without leaving any kind of marks.3D Printed Spring: Tips & Tricks to Print Springs - All3DP

3D Printed Spring: Tips & Tricks to Print Springs.

Posted: Sun, 07 May 2023 07:00:00 GMT [source]

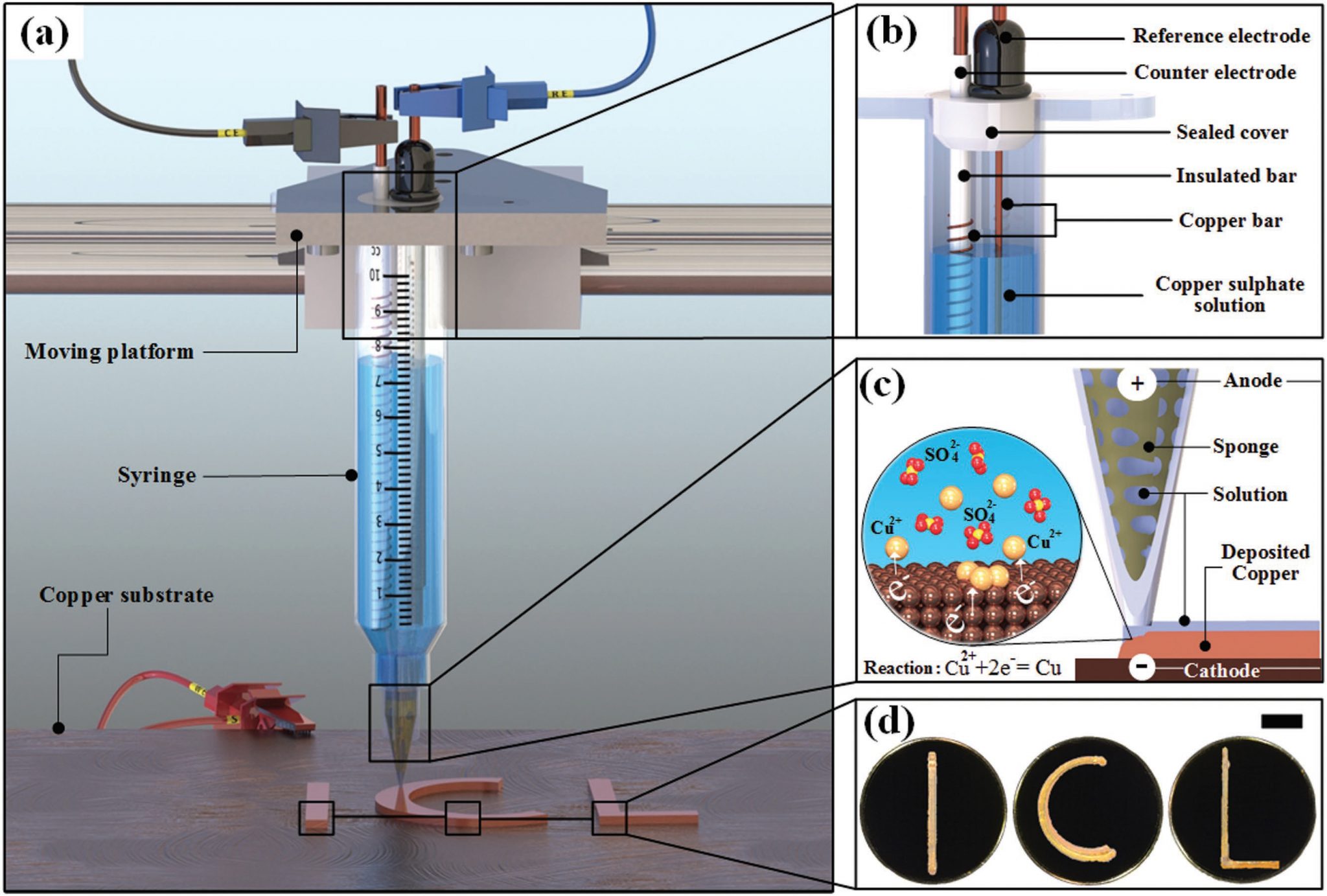

Electroplating Plastic 3d Prints

Normally, this is about 10 mm/s to 20 mm/s second less than the speed for the interior wall. If the interior wall surface rate is readied to https://large-format-printers.b-cdn.net/Printing-Glossary/offset-printing/the-best-3d-printer-filaments-in337614.html 40 mm/s, 25 mm/s must function best. However, for smaller sized designs, you can also establish it to ~ 30 mm/s to keep the rate distinction as low as feasible. Attempt a couple of worths till you discover the one which supplies good assistance for the model, however also escape easily when it's time to eliminate them. Cooling is likewise an additional key point to bear in mind when attempting to obtain ideal prints.Why are my 3D prints so negative?

One of the most typical reason is just that the print simply does not bond to the surface area of the print system. The filament needs a distinctive base in order to adhere, so to address the concern you''ll need to create a much better bonding surface area. An unlevel print system can be an additional significant problem.

Social Links