Houston Garbage Disposal Installation: Upgrading Old Units

If you have lived with the same garbage disposal for more than a decade, you start to sense its age. The pitch of the motor changes, resets become frequent, jams show up after simple meals, and the sink takes longer to drain. In Houston, where many kitchens shoulder heavy duty entertaining and year-round cooking, disposals work harder than you think. Upgrading an old unit is not just a convenience play, it touches plumbing reliability, food safety, and even household energy use. With the right choice and a careful installation, you can cut noise, reduce clogs, and avoid those late-night emergency calls that always seem to land on a holiday weekend.

The telltale signs your disposal is past its prime

Most homeowners stretch a disposal until it gives up. That is understandable, but it leads to surprise failures. Units built in the mid-2000s through early 2010s typically last 8 to 12 years under normal use. Heavy-use kitchens, or homes that frequently grind fibrous scraps, sometimes only get 6 or 7. The clearest indicator is a mix of issues, not just one. You flip the switch, it hums but does not spin, then it only clears after several resets. The sink backs up even when the trap is clean. The grinding chamber looks chewed up and you see rust flakes. The motor trips a breaker when you run it alongside a dishwasher. Each symptom has its own fix, but when they stack, replacement makes more sense than patching.

Houston’s water chemistry contributes to corrosion inside the grinding chamber. That is not a knock on the city, just a reality of mineral content interacting with steel parts over years. Add in a disposal that was undersized for the family’s cooking volume, and you start to see why older homes around Bellaire, Westbury, or Oak Forest call for frequent Garbage disposal repair. Sometimes you can coax another year out of an old warrior, but a modern unit can quietly handle what the old one choked on, while using less power and water with each grind.

Matching the unit to the kitchen

Disposals are not one-size-fits-all. You will see models with fractional horsepower ratings, different feed styles, and noise claims that vary from a whisper to a jet engine. The trick is to map your actual use to these specs instead of letting the box art decide.

Horsepower sits at the top of the decision tree. For a single-occupant condo or a rental where cooking is light, a 1/3 HP unit can work, though I seldom recommend it in Houston kitchens. For small families and average use, 1/2 HP is the baseline. If you cook regularly and want fewer clogs through the trap, 3/4 HP is the sweet spot. For busy households, avid cooks, or anyone who wants to grind denser scraps like small chicken bones and harder vegetable trimmings, go 1 HP. The cost delta over 10 years of service is modest compared to the benefits. I have replaced countless 1/2 HP units in Montrose and Spring Branch with 3/4 HP models, and the call-backs for jams almost disappear.

Noise control is a bigger deal than people expect. The first time you run a well-insulated disposal, you realize how much quiet you have been missing. Manufacturers use baffles, thicker housings, and sound-dampening mounts to reduce decibels. In open-plan homes, that matters. If you have kids napping or Zoom calls happening in the next room, a better-insulated 3/4 HP or 1 HP unit earns its keep.

Materials and grind stages come next. Stainless steel components last longer in Houston’s humid climate, especially under sinks that vent poorly. Look for multi-stage grinding if you care about smoother operation and fewer large particles hitting the P-trap. Many mid- and upper-tier units now include anti-jam features that reverse momentarily at start-up, which avoids that hum-then-click dance that old units play.

Finally, confirm fit and compatibility. Measure the under-sink space, check the sink flange diameter, and identify your current mounting system. If you have a septic system around areas like Cypress or the northern suburbs, it is worth choosing a disposal designed for septic compatibility, which tends to be gentler on the system and sometimes includes bio-charge options.

What a proper installation really looks like

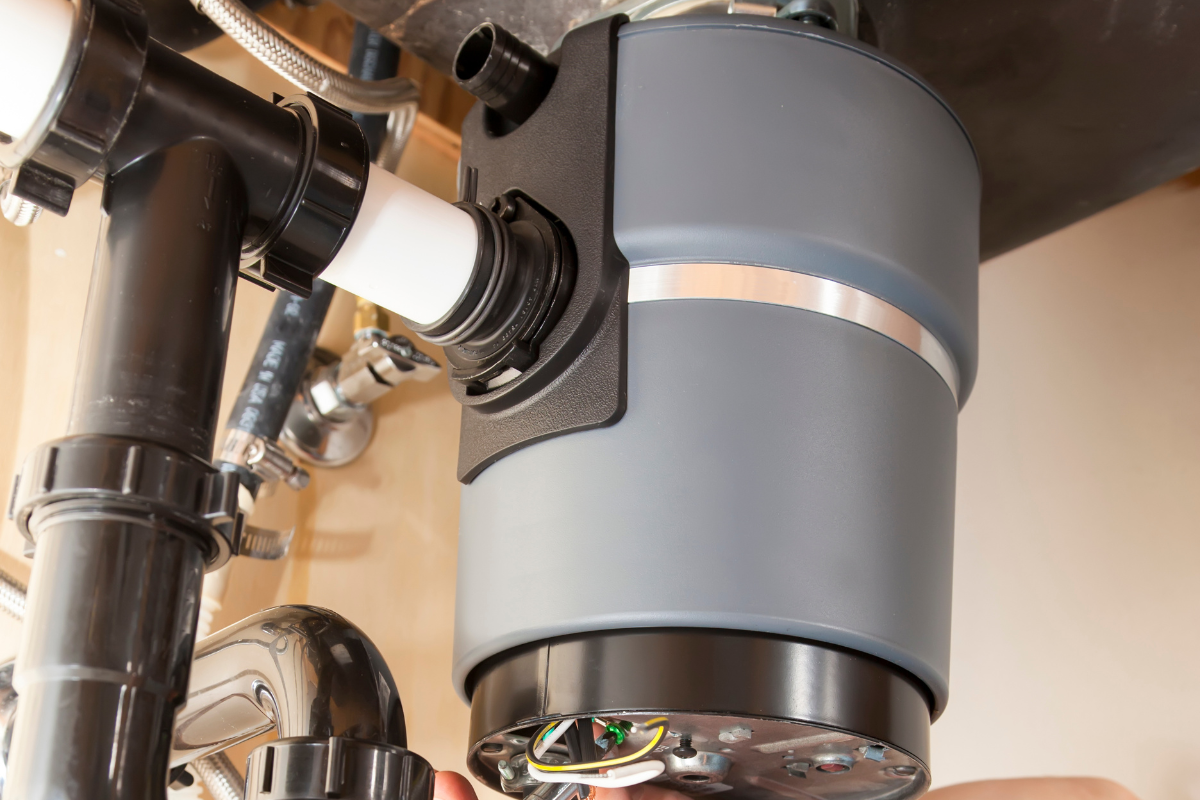

You can install a disposal DIY if you are handy with hand tools and comfortable with plumbing and light electrical work. That said, I have seen enough slipups to know where projects go sideways. A professional who does Garbage disposal installation Houston wide will run through a consistent checklist, not because they love checklists, but because small misses cause big headaches. This is what “right” looks like:

The mount matters. The sink flange and mounting ring must be seated with an even bead of plumber’s putty or an approved gasket. Over time, sinks flex. A thin or uneven seal lets water wick into the cabinet or corrode the mount. A pro will snug the mounting ring incrementally, then wipe excess putty after a short settle time before final tightening.

Drain alignment needs attention. A disposal outlet sits lower than a standard basket strainer, so you often need to rework the trap arm height. If the trap sits higher than the outlet, water will sit in the chamber and create odor. Too low, and you lose the trap seal. The installer should dry fit the tailpiece, baffle tee, and trap so the outlet has a smooth, sloped path. Avoiding unnecessary 90-degree elbows reduces clog risk.

Dishwasher connections deserve respect. The knockout plug inside the disposal’s dishwasher inlet must be removed cleanly. I still find unremoved knockouts causing dishwasher backups. Use a new dishwasher hose with a proper high loop or an air gap where code requires. In older Houston homes, the loop is common and acceptable, but if you remodel, consider adding an air gap for best practice.

Electrical safety comes first. If the existing disposal hardwires into a junction box, that connection needs to be inside an approved enclosure with strain relief. If you shift to a corded disposal, use a dedicated receptacle under the sink. Many kitchens run disposals and dishwashers on a shared circuit, which sometimes trips when both run at once. A good installer will check the breaker rating and wire gauge, then advise on separation if nuisance trips have been happening.

Leak testing is not a quick rinse. A pro will fill the sink, dye the water, then release it while inspecting every joint with a dry paper towel. They will also run the dishwasher for several minutes to check for seeping at the inlet hose. Catching a bead of water during installation beats finding a swollen cabinet floor a month later.

When repair still makes sense

Not every tired disposal needs to retire. A jam caused by a peach pit or bottle cap can be cleared from the bottom with a hex key and a reset. A worn rubber splash guard can be replaced, restoring flow and cutting noise for a few dollars. If the unit hums but does not start, a new start capacitor or a thorough cleaning sometimes brings it back. For homeowners seeking Affordable Garbage disposal repair, the sweet spot lies in small, targeted fixes that extend life without sinking money into a dying motor.

I tell clients to consider repair if the unit is younger than 5 years, shows no corrosion in the chamber, and has a simple, identifiable failure. If the motor still runs smoothly and quietly once cleared, Kitchen disposal repair Houston options will often include baffle replacement, tailpiece rework to improve drainage, and a fresh reset switch. Those small interventions can buy time, especially if a remodel is on the horizon and you would rather budget for a sink upgrade later.

If your unit is older than 8 to 10 years and you see chamber rust, water marks around the mount, or frequent breaker trips, it is better to put dollars toward a replacement. Spending half the cost of a new unit to repair an old one is rarely wise.

The Houston-specific wrinkles

Our city’s kitchens vary from mid-century bungalows with shallow cabinets to new builds with deep farmhouse sinks and double bowls. That variability affects disposal choices and installation details more than people think. Shallow cabinets can turn a 1 HP unit into a knuckle buster because the larger housing clips the back wall or an existing water filter. Deep farmhouse sinks often push the disposal food waste grinder installation outlet below the existing trap height, which calls for reconfiguring the trap arm. In some cases, you also need to shorten a tailpiece or adjust the wall drain stub to maintain the trap seal.

Climate and pests play a role too. In humid months, under-sink spaces trap moisture. A small, slow leak at the sink flange can warp a cabinet base in weeks. Houston’s occasional roach traffic loves damp, dark spaces, and a damp splash guard is an invitation. A new disposal with a fresh baffle, properly sloped drain, and tight seals helps keep odors down and pests uninterested.

City codes and permitting can come up during larger kitchen projects. If you are only swapping a like-for-like disposal, you generally do not need a permit. If you run new wiring, add a new circuit, or rework plumbing within a remodel, you should pull the appropriate permits and ensure GFCI protection where required. Reputable providers who handle Garbage disposal repair and replacement will flag these issues up front.

The trade-offs between batch feed and continuous feed

Most Houston homes use continuous-feed disposals, controlled by a wall switch. They are quick and convenient, which suits busy kitchens. Batch feed units start only when a special stopper is in place. This design adds safety, especially around curious kids or rental units where silverware finds its way into the chamber. Batch feed models tend to be quieter and reduce the chance of accidental drops. The trade-off is speed. If you peel a bag of potatoes, continuous feed keeps up without pausing.

I recommend batch feed for small households, rental units where you want to limit misuse, or where countertop outlets are limited. For families who cook daily, a well-insulated continuous-feed unit with a reliable splash guard hits the mark.

Disposals and dishwashers: the important relationship

The disposal is the gatekeeper for a dishwasher’s drain line. If the chamber holds water or the baffle clogs, the dishwasher will not drain well. People often assume the appliance is at fault, but a quick test tells the story. Run the disposal with water for 15 seconds, then run the dishwasher drain cycle. If it clears, the disposal or its connections need attention.

During installation, the technician should route the dishwasher hose with a high loop that fastens beneath the countertop. That loop prevents backflow. The hose barb on the disposal should be smooth and free of leftover knockout fragments. Clamps need to be snug but not overtightened, which can chew up the hose and create a slow leak. This is one of those small details that separate a clean job from a callback.

What to expect when upgrading an old unit

The swap itself usually takes an hour to two hours when the plumbing cooperates. Older units sometimes fight on the way out. The mounting ring binds, or the sink flange twists because the putty has hardened like rock. Under-sink shutoffs may be stuck. A patient, methodical approach keeps the sink safe. Expect the installer to lay towels, use a bucket for the trap water, and keep hardware organized. A small cordless work light helps spot drips.

If the old disposal was undersized, be prepared for a small reconfiguration. A larger unit may require shifting the trap or replacing a rigid tailpiece with a slight offset. None of this is complicated, but it does add time. If your under-sink space hosts a water filter, RO tank, or pull-out trash, plan the layout so you can still access the reset button and manual hex port.

Once installed, noise will be the pleasant surprise. Modern units run with a lower pitch and less vibration. The second surprise is how quickly water clears. A clean baffle and correct trap height allow a full sink to drain without glugging.

Cost, value, and the logic of spending

You can buy a bargain disposal for less than a family dinner out, but you will hear it and maintain it for years. In the Houston area, a solid 3/4 HP disposal with stainless steel grinding components usually lands in a price band that feels fair for the longevity. Professional installation adds to that, especially if the trap needs rework or an outlet needs to be added.

The value case becomes persuasive when you factor in service calls you avoid. If you have paid for two or three Garbage disposal repair visits over the past couple of years, those dollars would have covered a better unit. One of my clients off Kirby Drive had a 1/2 HP din that jammed twice a month. We stepped up to a 1 HP unit with anti-jam features and a correctly sloped drain. Their sink has been drama-free for two years, and the dishwasher smells better because there is no standing water in the line.

If budget is tight, talk to a provider who offers Affordable Garbage disposal repair alongside replacements. They can evaluate whether a lower-cost mid-tier unit fits your use without scrimping on essentials like stainless components and decent sound insulation. Skipping the bells and whistles is fine, but do not skip build quality or a safe electrical connection.

Avoiding the most common mistakes

Disposal issues trace back to four habits more than anything else: wrong scraps, wrong water use, poor cleaning, and ignoring early warning signs. On the first point, avoid stringy peels, large bones, coffee grounds in bulk, and fats that solidify. The occasional small chicken bone is fine in a 3/4 HP or 1 HP unit, but treat it like a spice, not a main ingredient. Run cold water while grinding, then a few seconds afterward. Cold water helps fats stay solid so the impellers can chop them, while the follow-on rinse clears particles into the larger drain line.

Cleaning a disposal does not require bleach cocktails or abrasive gadgets. Ice helps scuff the chamber, citrus peels disposal motor replacement freshen the baffle, and a spoonful of baking soda followed by a little vinegar loosens film. Do not forget the underside of the splash guard. That is where odors live. Pull it out if your model allows, or flip it inside out with gloved fingers and a brush. If you see tears or it has stiffened, replace it. The cost is small and the effect is large.

Finally, pay attention to subtle changes. A deeper hum, slower drainage, or frequent resets are not quirks to live with. They are early warnings that protect you from an overflowing sink at the worst time. A quick call to a local Kitchen disposal repair Houston tech can keep small issues from becoming cabinet damage.

A brief, practical buying and installation checklist

- Measure under-sink clearance, including depth to the back wall and height to the trap, before choosing a unit.

- Match horsepower to use: 1/2 HP for light, 3/4 HP for typical, 1 HP for heavy use and quieter operation.

- Choose stainless steel grinding components and good sound insulation where possible.

- Verify electrical: decide on hardwire versus cord, confirm GFCI where required, and avoid overloading a shared circuit.

- During installation, insist on proper trap height, a clean dishwasher knockout removal, and a thorough dyed-water leak test.

Troubleshooting a legacy unit before you decide

If you have not committed to replacement yet, a short diagnostic can clarify the path. First, cut power and check for chamber obstructions with a flashlight. Use the supplied hex wrench on the bottom of the motor to work through a jam, then hit the red reset button. Restore power, run water, and test. If it spins freely and sounds normal, your disposal may have life left. Next, inspect the splash guard. If it is clogged or warped, swap it. That alone can speed drainage and quiet the unit.

If the disposal still bogs or trips a breaker, look at the electrical draw. Many older homes share a 15-amp circuit for disposal and dishwasher. If both trip when run together, consider spreading loads or upgrading the circuit. If the unit smells despite cleaning, shining a light into the chamber can reveal corrosion. Rust pits along the grind ring indicate a kitchen sink plumbing near-term replacement. Likewise, if you see water weeping around the mounting ring after a full-sink test, the seal may be failing. Those are red flags for replacement rather than repair.

Partnering with a local pro pays off

Houston’s service landscape includes handymen, plumbers, and dedicated kitchen specialists. Disposals sit at the intersection of plumbing and electrical, so experience matters. A seasoned tech will help you pick the right unit, note quirks of your sink and cabinet, and perform the install cleanly. They also stand behind the work. If a baffle weeps or a clamp loosens, they return and make it right.

Providers who handle both Garbage disposal repair and replacements bring a practical eye. They do not need to sell you a new unit to earn your business, and they can suggest maintenance habits to extend the life of what you have. If you are searching for Garbage disposal installation Houston options, ask a few specific questions before booking: do they leak test with a full sink, will they adjust trap height if needed, and how do they handle dishwasher connections? Clear answers to those questions usually predict a smooth job.

The payoff of a well-chosen upgrade

After the install, the changes show up in small, daily moments. The sink clears without a gurgle. You can carry a conversation while the unit runs. Your dishwasher drains cleanly without the faint, swampy odor that haunted the old setup. Maintenance becomes simple: a quick rinse, a periodic clean, and common sense about what you feed the chamber.

An upgrade is not just a new gadget under the sink. It is a quiet fix for a noisy corner of domestic life, a nudge toward better plumbing health, and a relief when the house is full and dishes pile up. Over ten years, that steadiness adds up. Whether you land on repair today or a replacement this season, making the call with clear eyes saves time, money, and a fair amount of aggravation.

DYZ Plumbing, LLC

Address: 1220 Blalock Rd, Houston, TX 77055

Phone: (832) 877-9600