Houston Garbage Disposal Repair: Motor, Blades, and Bearings

A garbage disposal seems simple from the sink side. Flip a switch, it hums, food disappears, the kitchen stays tidy. Inside the housing, though, a small electric motor spins a flywheel where two pivoting lugs fling food against a stationary shred ring with serrated teeth. There are no open “blades” like a blender, just a compact hammer-mill that relies on torque, friction, and water flow to break waste down finely enough for the drain line. When a disposal starts to misbehave, most problems trace back to the motor, the impeller lugs and grind ring, or the bearings and seals that keep everything aligned and dry. In Houston, where water hardness, heavy cooking, and fast turnarounds in rental properties combine, these components see hard use and fail in predictable patterns.

I’ve repaired and replaced hundreds of units in neighborhoods from Montrose to Katy, in high-rises downtown and slab-on-grade homes in Cypress. The symptoms vary, but the anatomy of the fix is steady. The sections that follow break down how to read the sounds and smells, what can be salvaged, and when a replacement is the wiser spend. If you are searching for affordable garbage disposal repair or planning a new garbage disposal installation Houston homeowners can rely on, the details here will help you talk to a pro and make clear-eyed decisions.

How a disposal actually grinds

It helps to know what you’re listening to. In a standard continuous-feed unit, the motor turns at roughly 1,725 RPM. That motor shaft connects to a sealed bearing and a turntable inside the grind chamber. Two steel lugs mounted on that turntable swing freely on pivots. When you start the unit and run cold water, those lugs fling outward, sweeping food scraps across a fixed steel ring with sharp ridges. The interaction between spinning lugs and stationary ring does the cutting. Water carries the slurry past a rubber baffle, through the P-trap, and into the main drain.

Units marketed at higher horsepower, say 3/4 to 1 HP, usually have better noise insulation, stainless interiors that resist rust, and more robust bearings. Lower horsepower units, especially those in the 1/3 to 1/2 HP range installed in budget apartments, lack headroom for heavy grinding and bog down when fed fibrous or starchy scraps. That’s where many Houston service calls start.

The noise map: decoding sounds into causes

A disposal speaks loud and clear once you know the dialect. A steady hum with no spin means the motor is receiving power but stuck. A growl or metallic rattle points to a jammed or bent lug hitting the ring. A screech or dry whine after startup hints at bearing failure. A rhythmic clunk usually means a foreign object is bouncing around, often a bottle cap, coin, or a small screw that fell during a faucet install. A chirp followed by a hot electrical smell can signal the reset overload tripping as the motor overheats.

Two recurring Houston examples stand out. In older bungalows in the Heights, original galvanized drains collect scale. Someone drops eggshell shards, which wedge in the ring. The homeowner flips the switch twice, trips the thermal overload, and calls for kitchen disposal repair Houston techs handle almost daily. In newer construction near Pearland, large double-bowl sinks often share one trap and one vent run. When installation angles are off, backflow and air lock cause slow drains that make the disposal sound strained under normal loads.

Motors: why they stall, hum, or die

Most residential disposals use shaded-pole or induction motors with a simple start circuit. They are sealed against water intrusion but not invincible. Houston’s water hardness leaves mineral deposits that, over years, corrode internals and the grind chamber. The motor itself fails less often than the components it drives, so a hum without motion is usually a stuck flywheel rather than a burned-out motor.

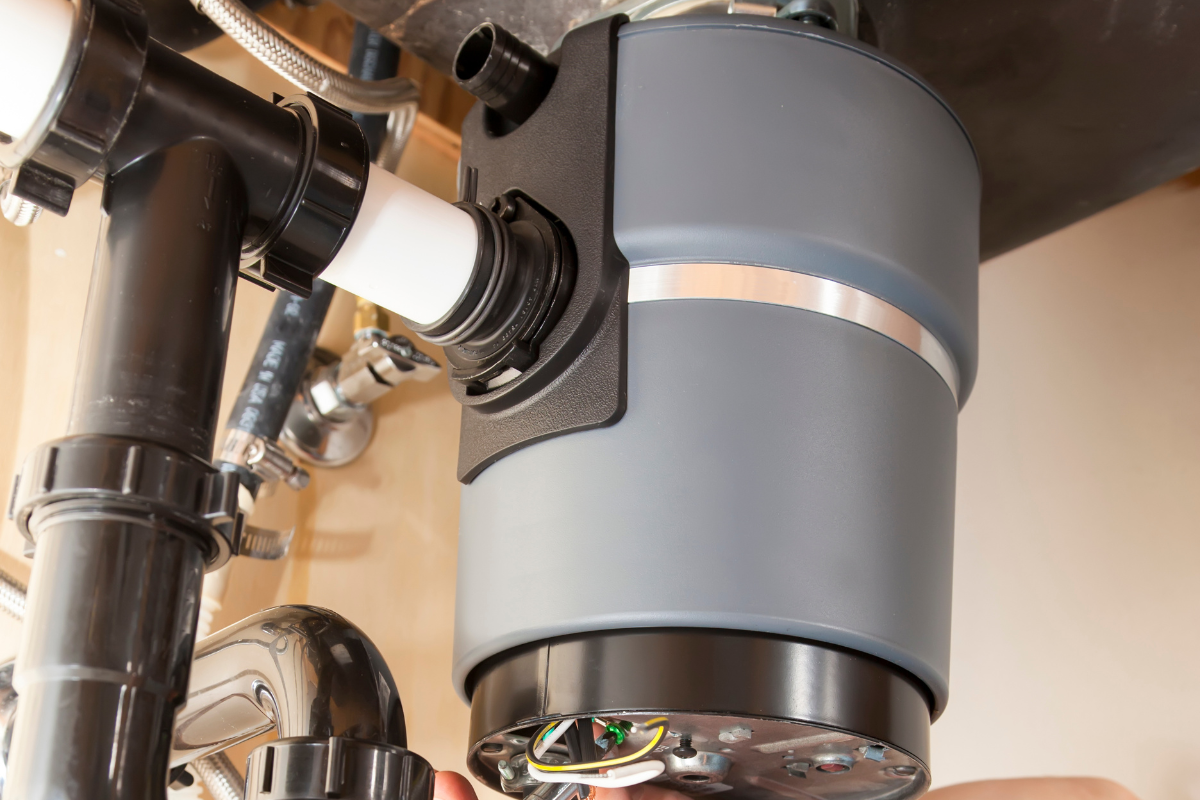

A technician’s first moves are safe and simple. Kill power at the switch, then confirm at the breaker or unplug it under the sink. Insert a 1/4 inch Allen wrench into the hex recess on the bottom of the motor and crank the flywheel both directions to dislodge debris. Tap the bottom of the housing with the heel of your hand while turning. Restore power briefly to test. If it spins up cleanly and water flows, the motor is fine and you’ve cleared a jam. If it starts, then stalls again under light load, the capacitor, windings, or bearings may be on the way out.

Heat and moisture are the enemies. I’ve opened failing units to find rust freckles on the motor can and a telltale trail of water from a slow sink flange leak above. The motor’s insulation cooks slowly over months each time the overload trips and resets. That cycling weakens the windings until you get a motor that runs for thirty seconds, then goes dead until it cools. In those cases, “affordable garbage disposal repair” means replacement. You can swap a start capacitor in some models, but by the time the motor trips repeatedly, other parts are already aging out. Parts availability for low-cost brands is spotty, and labor quickly outpaces the price of a new mid-range unit.

For homeowners who cook daily and run the disposal twice a day or more, a 3/4 HP motor with better torque reserves prevents the stall-hum-reset loop that kills smaller units. That choice often pays for itself by avoiding one service call every couple of years.

Blades, lugs, and the shred ring: not knives, but wear parts

When people say “blades,” they mean the two steel lugs that swing and batter scraps against the ring. Those lugs do not cut like a knife. They rely on free movement at their pivots to fling outward and on square edges where they hit the ring. Over time, two things go wrong. First, grease and starch gum up the pivots so the lugs stick. Second, repeated contact with bones, pits, and metal wear down the edges. Sticky pivots cause weak grinding and long run times, which overheat the motor. Worn lugs and a polished ring leave fibrous strands intact, which clog downstream.

You cannot sharpen these parts in place, and attempts to scour them with ice or citrus peel are overrated. Ice can knock loose some debris, but if the pivots are lacquered with fat, you need a controlled cleaning. An experienced tech will isolate power, remove the unit from the sink, and split the housing on serviceable models to clean the lug pivots and inspect the ring. Many modern units are crimped and not designed to be opened, so the practical choice is replacement. If you have a premium disposal with a bolted housing, a cleaning plus new lugs can restore performance, but the parts and labor usually rival a new unit unless you value keeping a high-end brand in service.

Anecdotally, I see more gummed lugs after holiday seasons. Families in West U or Bellaire hosting big meals push potato peels, turkey skin, and gravy down the sink in quick succession. Hot water liquefies fat temporarily, cold water later re-solidifies it on internal parts. If you must run scraps after cooking, use plenty of cold water first, run the unit empty for ten seconds, then feed in small handfuls while keeping the water going. A final 20 to 30 second rinse clears the chamber and the trap. That habit keeps the lugs swinging freely longer.

Bearings and seals: the quiet culprits behind leaks and screeches

The bearing stack supports the spinning turntable. When those bearings dry out, you hear a sharp metallic whine at startup, often accompanied by a faint grinding feel if you turn the flywheel with an Allen wrench. Seals around the motor shaft prevent water from dripping into the motor cavity. A failed seal turns into a slow leak from the bottom of the disposal, usually showing up as a crusty trail on the housing or a damp mat under cleaning supplies. Once water reaches the lower bearing, corrosion progresses quickly.

Can you replace bearings and seals? On paper, yes, if you can source exact parts and the housing is serviceable. In practice, most residential disposals are not intended for rebuilds. The time to disassemble, press bearings, reseal, and test exceeds the cost of a new unit. Commercial disposals in restaurant kitchens are a different category, but for homes in Houston the smart money for bearing or bottom-leak failures is a replacement. A leak at the sink flange or dishwasher inlet is a different story, and that repair is often straightforward with new putty or a hose clamp.

If your disposal screeches but does not leak, act quickly. Running it through the noise on the assumption it will “work itself out” accelerates wear and increases the chance of a bottom leak that can damage cabinetry and swell particleboard bases.

Drainage matters as much as horsepower

I’ve replaced perfectly good disposals that were blamed for slow drains. The root cause was a poorly sloped waste arm or a trap set too high relative to the outlet. In Houston’s slab homes, trap arms sometimes run long to meet the stack, and the water line inside the pipe sits close to level. Food slurry from the disposal needs velocity and air behind it. Without adequate slope and venting, it lingers and leaves a paste that dries into concrete.

During a service call for garbage disposal repair, I check three simple things with a torpedo level and a flashlight: the fall from the disposal outlet to the trap, the fall from the trap to the wall stub, and the vent tie-in height if visible. A few degrees of added slope reduces callbacks dramatically. If the house has a history of backups, upsizing the trap arm from 1 1/2 inches to 2 inches where code allows, along with a new disposal, creates space for slurry to move.

Apartment maintenance teams often fight repeat clogs because upstairs tenants treat the disposal as a trash chute. In those buildings, installing a baffle tee or short run of larger diameter downstream helps, but tenant education is what sticks. No coffee grounds, no rice, no banana peels. Those items expand or string together and stick to the first rough patch in the pipe.

Repair versus replace: where the money lands

Every homeowner wants a fair shake, and “affordable garbage disposal repair” can mean different things depending on context. Here’s how I frame the decision at a kitchen sink in Houston:

- If the unit hums and trips, and a hex wrench frees it immediately with no screeching, repair is usually a cleaning and reset. That is the best case. If it repeats weekly, consider upsizing horsepower.

- If the unit leaks from the bottom or screams like metal on metal, replacement is the cost-effective path. You can chase bearings and seals, but the economics don’t favor it in residential models.

- If the chamber is rusted through or the grind ring is polished smooth, replacement makes sense. You cannot sharpen the ring, and corrosion will return.

- If the unit is under five years old, high-end, and bolted not crimped, a teardown to clean lugs and pivots may be worth the labor.

- If you are renovating or replacing a sink, seize the moment to install a new disposal and fresh flange, because labor overlaps and you avoid disturbing cured putty and gaskets later.

That middle ground is where judgment matters. A landlord in Midtown may prefer a basic 1/2 HP unit knowing it might be swapped every three to five years, while a homeowner in Memorial who cooks daily will value a quiet 1 HP with stainless internals that runs a decade with minimal fuss.

Installation details that prevent 80 percent of headaches

Plenty of problems tie back to the first day the unit met the sink. A proper bead of plumber’s putty under the flange, tightened until it squeezes uniformly, prevents that slow flange leak that cooks a motor. Aligning the discharge elbow to a trap with adequate fall keeps food moving. Matching the dishwasher hose to the disposal inlet with the correct barb size, kicking out the inlet knockout cleanly, and securing with a stainless clamp stops side leaks.

Houston’s building stock throws in extra wrinkles. In homes with cast-iron waste stubs that were cut and refitted decades ago, the interior of the stub may be rough with scale. A quick pass with a wire brush and the right slip-joint washer makes the difference between a dry install and one that drips after a week. In condos with tight under-sink space, the orientation of the disposal and the decision to use a low-profile trap saves clearance for a pull-out trash can and prevents stress on connections. These are the small choices that separate a tidy installation from one that needs attention months later. When you search for garbage disposal installation Houston providers, ask them about trap elevation and flange sealing methods, not just horsepower. The answers tell you if you’re getting craft or just a swap.

What you can safely do yourself

Plenty of Houston homeowners handle basic garbage disposal repair without calling a pro, and that’s a good thing. Use the right steps, protect your hands, and know when to stop. Here is a short, safe sequence for a stuck unit, in plain terms, not a daredevil move:

- Cut power at the switch and confirm the unit is off. If it plugs in, unplug it. If it’s hardwired, flip the breaker.

- Shine a light down the sink with the splash baffle removed if it lifts out. If you see a fork, bottle cap, or bone shard, use long pliers or tongs to remove it. Never put your hand inside.

- Insert a 1/4 inch Allen wrench into the hex at the bottom center of the disposal and work it back and forth until it spins freely both directions.

- Press the red reset button on the bottom. Restore power. Run cold water, then bump the switch in short bursts to test. If it spins freely, let it run with water for 20 seconds to clear.

- If it hums strongly but does not spin, trips immediately, or screams, stop and call a pro.

That’s one of only two lists you will find here, because the sequence matters. The bigger picture is caution. I’ve responded to calls where a homeowner tried to pry a jam with a butter knife and lost the knife into the chamber, creating a worse jam. If you can’t see the object clearly, better not to fish blind.

What to avoid putting down the disposal

Not everything belongs in a disposal, no matter what manufacturers imply in glossy brochures. Houston’s combination of hard water and long horizontal drain runs exaggerates the effects of certain scraps. Three categories cause most trouble. Fibrous peels and husks form ropes that lasso the lugs and resist shredding. Starches like rice and pasta swell and glue themselves along pipe walls, trapping more debris. Grease and congealed fat gum up pivots and coat the shred ring. Coffee grounds are a special case; they seem fine going down, but the fine grit packs in traps like wet sand.

Clearing habits help. Run cold water, feed small amounts, keep the flow going for those extra 20 to 30 seconds at the end. Cold water helps fat solidify in small particles that move with the stream rather than smear. It is not a cure-all, but it buys time.

Noise and vibration: quieting the beast

If your disposal sounds like an unbalanced washing machine, the mounting and armor matter. Rubber isolators where the disposal meets the sink, along with proper alignment of the mounting ring, damp vibration. Stainless sinks amplify noise more than cast iron or composite. That’s why two houses with the same model can sound different. Some higher-end disposals include extra sound insulation around the motor housing. In Houston remodels, homeowners often change from cast iron to thin stainless sinks, then complain about a louder disposal. In those cases, stepping up one model class reduces the din more effectively than tinkering with the old unit.

Vibration can also signal a bent turntable from a past jam where someone ran the unit with a spoon inside. The wobble transfers to the sink and pipes. If you feel that pulsing shake through the counter, inspect for foreign objects and bent parts. Bent internals usually justify replacement. Trying to true a warped turntable in place is a lesson in frustration.

Special note for dishwasher connections

Most disposals tie into a dishwasher drain hose. That connection has a knockout plug inside the disposal inlet that must be removed on install. I’ve arrived at new homes where the dishwasher won’t drain because no one punched disposal wiring repair that plug. The fix takes thirty seconds with a screwdriver and pliers. On the other end, an air gap or high loop matters. In Houston municipalities that enforce air gaps, you’ll see the little dome on the sink deck. Elsewhere, installers rely on a high loop under the counter. Without one of those safeguards, dirty water can siphon back into the dishwasher. It’s an avoidable hygiene issue.

Dishwasher discharge carries fine food particles and detergent. Over time, detergent film can also slick the disposal interior. If you notice a chemical smell or foam, run cold water a little longer after a dishwasher cycle to flush the chamber.

Matching unit to household

Choosing the right disposal is less about brand loyalty and more about realistic use. A one-person apartment in Midtown that cooks twice a week can thrive with a quiet 1/2 HP unit with stainless grind components. A family of five in Spring Branch that cooks nightly and entertains on weekends benefits from a 3/4 or 1 HP unit with auto-reverse features that back out of minor jams. Stainless interiors resist the rust bloom you see in cheaper painted steel chambers, especially with Houston’s mineral content. Warranty terms tell a story too. A 10-year or lifetime corrosion warranty often signals higher-grade internals that hold up in humid under-sink environments.

I often ask customers about the rest of their plumbing. If the kitchen line is old cast iron that snags debris, a stronger disposal won’t cure snags downstream. Sometimes the smartest “upgrade” is a short section of new PVC downstream of the trap, or a scaled and re-sloped run to the stack, done at the same appointment as the new disposal. The cost is moderate and the effect dramatic.

Real-world scenarios from Houston kitchens

A townhome in EaDo, two-year-old builder-grade 1/2 HP disposal, humming and tripping after a brunch. The culprit was a jam of avocado skins and a dull lug. We cleared it with the hex wrench, but the motor had tripped thrice that morning. Owner cooks daily, so we replaced it with a 3/4 HP stainless unit. The drain line had minimal fall, so we raised the trap by 3/4 inch and shortened the arm. That combination stopped the recurring slow drains. Cost was a bit higher than a straight swap, but there were no callbacks.

A rental in Gulfton, leaking from the bottom into a particleboard cabinet base. The flange had been weeping for months, corroding internals until the lower seal failed. We replaced the unit and, more importantly, scraped the old brittle putty and reset the flange with a new gasket pack. The owner authorized a thin PVC pan under the disposal as a cheap “notice” device, so the next leak, if any, would be visible before it soaks wood. Simple prevention that costs less than a cabinet rebuild.

A high-rise near the Galleria, disposal howling loudly, tenant insisted the motor was dying. The actual issue was a stainless sink with a thin gauge that resonated like a drum. The unit itself was fine. We added a rubber isolator ring, adjusted the mounting collar, and placed adhesive sound-deadening mats under the sink basins. The noise dropped to a tolerable level, no replacement needed.

When to call for professional help

Some repairs demand experience and the right touch. Electrical smells, visible smoke, water leaking from the motor housing, or a disposal that repeatedly trips the breaker are red flags. If you suspect a misaligned trap or a venting issue, a pro can read the pipe geometry and fix it in one visit. For homeowners searching for kitchen disposal repair Houston services, ask for a technician who will check alignment and drain slope, not just the disposal body. That approach prevents repeat visits and keeps your bill grounded in results, not guesswork.

If you are remodeling, coordinating garbage disposal installation Houston projects with sink and countertop installers avoids headaches. Once a new sink is in, clearances may change and a previously acceptable trap height can become a problem. A plumber who sees the whole picture will set the flange, confirm sink support, align the discharge, and test the dishwasher loop in one go.

Keeping it running: small habits that pay off

You can extend the life of a disposal with simple habits. Run cold water before and during grinding. Feed small batches. Let it run after the grind is done until the sound evens out, then count to 20 while the water runs. Avoid grinding stringy peels and large bones. Once a month, flush with cold water and a splash of mild dish soap while running to rinse films. If odors crop up, a cup of baking soda followed by a slow pour of white vinegar will foam, loosen residue, and then you can rinse with cold water. Skip harsh drain chemicals, which attack rubber parts and don’t fix mechanical issues inside the disposal.

For rentals, a small laminated card inside the cabinet with “what not to grind” saves service calls. In multifamily buildings I’ve worked with, that card, plus a starter strainer basket in the other sink bowl, cut clog tickets by half.

The bottom line for Houston homeowners

Disposals fail for legible reasons. Motors stall because they’re overloaded or their support parts are gummed up. Lugs lose their bite from wear and fat. Bearings complain before they give up, and seals tell on themselves with drips. The drain they feed either helps or hinders. When you face a choice between service and swap, weigh the age of the unit, the failure mode, the drain geometry, and your cooking habits. In many cases, repair means clearing a jam, resetting an overload, or resealing a flange. In others, replacement is the faster, cleaner, more affordable outcome over the next five years.

If you quiet garbage disposal options call for garbage disposal repair, ask the tech to explain what failed and why. A clear answer is a good litmus test. If you plan a new installation, match horsepower to use, invest in stainless internals where you can, and pay attention to the quiet stuff: slope, venting, and isolation. Do that, and the small machine under your sink will do its work without drama, quietly earning its space in the busiest room in the house.

DYZ Plumbing, LLC

Address: 1220 Blalock Rd, Houston, TX 77055

Phone: (832) 877-9600