Professional Garbage Disposal Installation in Houston: A Guide

Garbage disposals sit in a tough spot, both literally and figuratively. They live under the sink where space is tight and moisture is constant, yet they’re expected to grind food scraps quietly, never leak, and keep up with daily cooking. In Houston, they also have to handle mineral-heavy water, hurricanes that can knock out power, and homes ranging from 1940s bungalows to new builds with modern plumbing layouts. Installing one correctly is not a luxury. It protects cabinets from water damage, prevents electrical hazards, and keeps your kitchen sink from becoming a headache.

This guide pulls from years of field work around the Greater Houston area. It covers how to choose a disposal, what installation actually entails, how to avoid common traps that create leaks or clogs, and when to call for Garbage disposal repair versus replacement. If you’re shopping for Garbage disposal installation Houston services, or weighing an Affordable Garbage disposal repair instead of a new unit, the details below will help you make the call with confidence.

How a disposal fits into a Houston kitchen

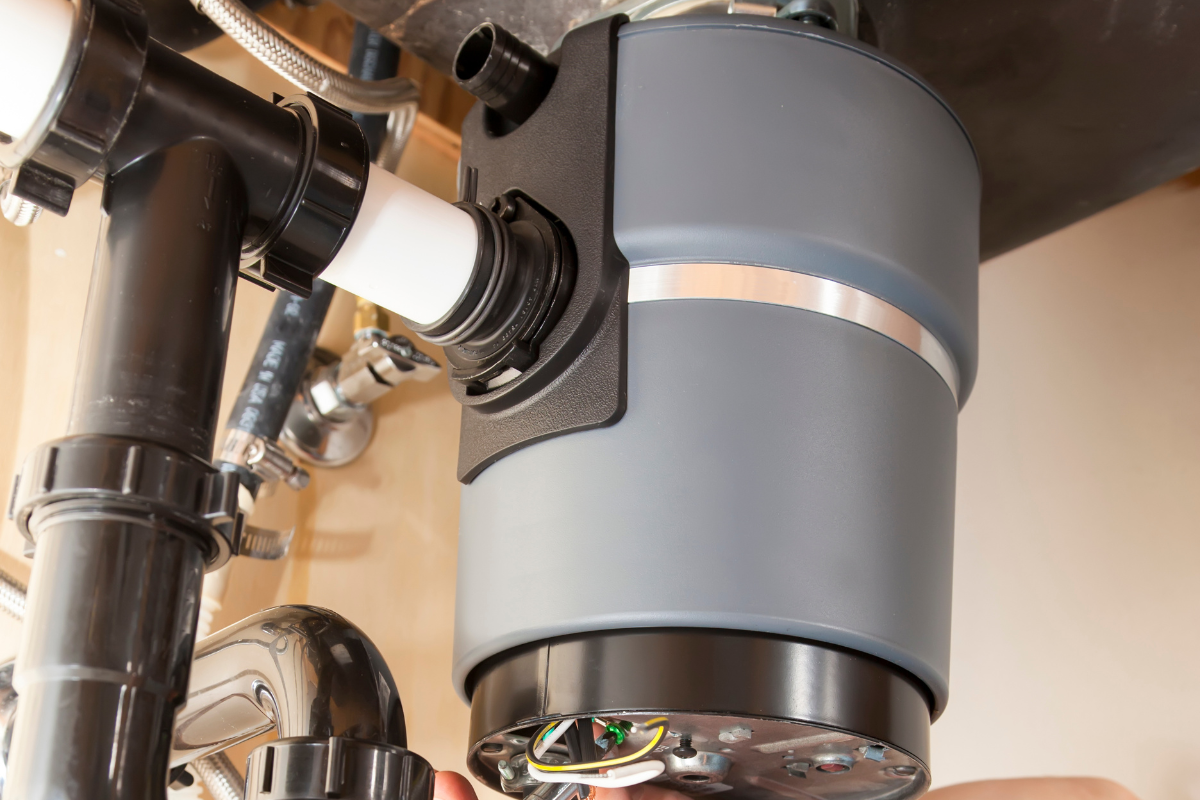

Disposals are simple machines with specific dependencies. They mount to the sink, tie into the drain and trap, tee into the dishwasher line if you have one, and either plug into a dedicated outlet or connect via a hardwired switch circuit. A well done install keeps everything aligned: no sags in the trap, no backflow from the dishwasher, no flexing that loosens the mounting ring.

Houston adds a few wrinkles. Many neighborhoods run on hard water, which accelerates mineral buildup around flanges and gaskets. Older homes may have cast iron traps or non-standard tailpieces that need adapters. During heavy rain events, sewer systems can be stressed. If the trap arm lacks proper slope or venting, the disposal side of the sink is often where slow drainage shows up first.

Choosing the right disposal for your household

Matching the unit to your household matters more than brand loyalty. I’ve replaced undersized disposals in five-year-old houses that never stood a chance in a busy kitchen. A careful selection can add years of quiet service and fewer calls for Kitchen disposal repair Houston technicians.

-

Power rating and use: Light-use households that mostly rinse plates do fine with 1/3 to 1/2 horsepower. Families that cook daily, grind vegetable peels, and occasionally handle small bones are better served by 3/4 to 1 horsepower. A stronger motor isn’t about bravado, it’s about avoiding jams, especially when you’re multitasking during dinner clean-up.

-

Grind technology: Most residential units use continuous feed, which runs while water is flowing and you feed scraps gradually. Batch-feed disposals use a stopper-style lid and are safer around curious kids, but slower. No grinding unit is a blender, so fibrous stalks and large bones remain a bad idea.

-

Sound insulation: If your kitchen is open to living areas, a well-insulated unit pays for itself in reduced noise. Higher-end models use better sound baffles and isolated mounts so conversations can continue without a hum underneath.

-

Corrosion resistance: Stainless steel grind components outlast galvanized parts in our climate, particularly with Houston’s humidity and mineral content. If you’ve had repeated rust around the sink flange, aim for stainless.

-

Mounting compatibility: If your sink already has a 3-bolt mounting system, staying with a unit that matches the ring can simplify the swap. That said, rubber gaskets compress over time, and an old mount is often the cause of the slow drip you noticed months ago. Replacing the full mounting assembly with the unit is rarely a wasted step.

-

Electrical status: If your sink base already has a switched outlet, choose a corded unit. If not, you’ll need either an electrician to add a receptacle or a hardwired model that ties into the existing switch. In either case, GFCI protection is recommended when the circuit serves countertop receptacles or is near a sink, which is nearly always the case.

What a professional installation really involves

The box makes it look quick: tighten a ring, twist and lock, plug in. The job can go smoothly, but there are details that separate a clean, long-lived install from one that leaks or vibrates. A typical call in Houston follows a rhythm.

First, the sink flange. Old plumber’s putty dries out, especially in homes where hot water and degreasers have washed over the flange for years. When I pull a failed unit, I often find the putty has turned to brittle crumbs. A good install involves fully cleaning the sink opening, applying a consistent bead of fresh putty or a manufacturer-approved sealant, setting the new flange, then pulling the mounting ring tight to evenly squeeze the seal. Over-tightening is common and can warp the gasket, inviting a slow weep that only shows up when the sink is full.

Second, the drain geometry. Disposals increase the height of the tailpiece exit compared with a straight basket strainer. If the wall stub-out is too high relative to the disposal outlet, you get a trap that sits too shallow or even back-slopes, which invites clogs. The remedy is often a new trap kit, sometimes a shallow P-trap, and in older homes a reconfigured trap arm with proper pitch. I keep multiple tailpiece lengths and a few 22-degree fittings on the truck because every cabinet looks a little different.

Third, the dishwasher connection. The knockout plug inside a brand-new disposal’s dishwasher port exists for a reason, but it’s amazing how many units I find with the plug still in place and the dishwasher line neatly clamped to it. The result is a dishwasher that backs up into the sink. On the flip side, removing the plug without a proper air gap or high loop can send disposal water into the dishwasher. In the City of Houston, a high loop under the counter is widely accepted, though some dishwashers integrate a backflow device. If your dishwasher manual requires an air gap, follow it.

Fourth, the electrical. Some houses have a switched outlet already under the sink, often on a split receptacle with the dishwasher. Others have a wall switch that controls a hardwired whip to the disposal. I test the circuit, confirm grounding, and check that GFCI protection exists where required by current code. If the unit is hardwired, I make the connection in a listed junction box with a proper strain relief, not loose behind the cabinet. For plug-in units, a factory cord avoids amateur splices.

Finally, the test. A thorough test includes filling the sink and letting water sit over the flange for a few minutes, then draining while watching all joints. I also run the dishwasher briefly to push water through the disposal branch. If the dishwasher hose is routed correctly, there should be no smell and no backflow.

Common mistakes that create leaks or noise

I get called for Garbage disposal repair more often than installation, and most issues trace back to install errors or habits. A few stand out:

The misaligned trap. If the trap arm is off by even a quarter inch, tightening the slip nuts can force parts together at an angle. It might look tight, but a month later you’ll see mineral stains where a drip formed. It also amplifies vibration. Using the right combination of tailpieces and couplings avoids this.

Skipping the support. Heavy disposals need a steady hand when locking them into the mount. If the rubber gasket isn’t seated evenly, the unit will wobble and hum. The mount should carry the load, not the drain connections.

Reusing a corroded mount. The old 3-bolt ring might look fine until you torque it. Years of moisture thin the metal and it splits. Replacing the entire assembly with the new one from the box prevents that midnight drip that shows up two weeks later.

Ignoring the vent. Slow drainage at a disposal often points to venting issues. A clogged or undersized vent can make the disposal side glug and belch. You can replace disposals all day and they’ll still struggle if the vent stack is blocked. When a customer mentions gurgling, I check venting before I recommend a higher-power unit.

Letting a cord dangle. A floating cord can contact hot discharge pipes or snag bins in the cabinet. Securing cords and hoses seems minor until someone yanks them by accident.

When repair makes more sense than replacement

Affordable Garbage disposal repair can stretch a unit’s life by a year or two if the motor and bearings are sound. For example, a bad reset switch, a jammed flywheel, or a leaking discharge gasket are straightforward fixes. Many jam complaints come from small objects like bottle caps that fall in unnoticed. Clearing the jam and resetting the thermal overload solves it.

Repairs make good sense when the unit is under 5 to 7 years old, not rusting, and quiet when running. A humming motor that trips the breaker may only need a flywheel freed and the capacitor tested on models that use one. Vibration often points to a dislodged splash guard or worn rubber mounts, both replaceable. If the leak is at a PVC slip joint, new washers and a proper realignment stop the drip. Kitchen disposal repair Houston service calls often turn into quick adjustments that don’t require new equipment.

Replacement is the better path when the chamber is rusting, the housing is cracked, or the motor howls even under light load. Another tell is recurring trips on the overload with no jam present. Units over a decade old that have started to stink even after thorough cleaning usually have biofilm embedded beyond easy reach. A new stainless steel model solves that in one visit.

Houston permitting, code, and practical safety

Houston’s code follows modern standards for kitchen circuits and plumbing venting, with updates over time. A homeowner swap of a like-for-like disposal typically does not trigger a permit, but additions to electrical service, new outlets inside cabinets, or major drain reconfiguration can. If your installation requires adding a receptacle under the sink, expect to bring the circuit up to current requirements. That often means a dedicated 120-volt circuit shared with the dishwasher or a properly sized branch with GFCI protection, depending on the layout.

Safety basics rarely get enough airtime. Always kill power at the breaker before you work under the sink, not just at the wall switch. Test with a non-contact voltage tester. If you hardwire a disposal, enclose connections in a junction box with a cover labeled for the device. On the plumbing side, support the trap and disposal so the drain connections aren’t bearing weight. Water and vibration are a bad combination when threads and washers are your seal.

Costs and what drives them

Most homeowners budget for the unit and a flat install fee. In Houston, a straightforward swap of a similar-sized disposal with an existing outlet typically lands in a modest range for labor. The unit can be anywhere from economy models to premium, depending on power and insulation. Extras tilt the number up: a new air gap, fresh trap kit, rewiring to add a GFCI outlet, or correcting an improper drain height.

Affordable Garbage disposal repair sits on a different scale. A jam cleared and reset is often a low-cost visit. Replacing a discharge gasket or a splash guard falls in that same tier. Leaks at the sink flange take longer because of the putty cure and alignment, though many sealants are ready for immediate use. When the repair bill approaches half the cost of a new unit, especially on an older, noisy model, replacement becomes the value choice.

A note on water quality and maintenance

Hard water leaves scale. Around disposals, it collects on the sink flange and the splash guard, and it hardens inside the discharge elbow. The fix isn’t fancy. Once a month, run a full sink of warm water with a small amount of dish soap, then drain while the unit runs. This flushes the trap and the disposal chamber. Ice cubes help knock loose small particles, though they won’t sharpen blades because disposals use impellers, not knives. Citrus peels freshen the splash guard but leave pith that can stick, so use sparingly.

If your home has a water softener, expect less mineral crust and longer gasket life. In homes without softening, plan on replacing the rubber splash guard every few years. It’s a small part that makes a big difference in smell control and noise.

What to expect on installation day

A clean install takes preparation more than heroics. I ask homeowners to clear out the sink cabinet and avoid running the dishwasher for a few hours beforehand. On site, I put down absorbent pads, disconnect the old unit, and assess what will be reused. The sink opening gets cleaned same-day disposal repair thoroughly. The new flange and mount go in, then the disposal is locked onto the ring. I cut and fit the trap components so they seat without tension. If there’s a dishwasher connection, I knock out the plug, collect it so it doesn’t rattle inside, and route the hose with a high loop to the underside of the counter.

On the electrical side, I either connect the factory cord to the unit or tie into a junction box with proper wire nuts and a clamp. The test phase is deliberate: flood the sink to check the flange, run the unit with cold water to check for vibration, run the dishwasher to confirm no backflow. Before leaving, I review safe use habits and give the homeowner the model and serial for their records.

Safe use habits that keep service calls at bay

Most disposal problems come from a short list of habits. Keeping to these saves money and hassle.

- Run cold water before, during, and for 10 to 20 seconds after grinding. It keeps fats solid so they pass through the trap, and it pushes debris fully into the drain.

- Feed gradually, not in handfuls. Overloading stalls motors and packs the chamber so tight the impellers can’t move.

- Keep fibrous items like corn husks, celery strings, and artichoke leaves out. They wrap around the impellers and cause jams.

- Avoid pouring cooking oil or bacon grease down the sink. Even with a good disposal, grease cools and coats the trap.

- Periodically clean the splash guard. Lift it and scrub the underside. That rubber harbors most odors people mistake for a failing unit.

Troubleshooting at home before calling for service

You can safely diagnose a few issues without tools. If you hear a hum but no grind, turn the switch off, shine a light, and check for a foreign object. Use tongs, not fingers. Many units have a hex slot underneath for a wrench to free a jam. After clearing, press the red reset button on the bottom. If the unit runs, listen for smooth operation and check for leaks.

If the disposal runs but the sink backs up, the clog is likely in the trap or wall stub, not the unit. A quick trap removal and cleanout solves most of these. DIYers often tackle this, but if the trap geometry looks improvised or corroded, calling a pro avoids cracking something that’s barely holding together. When the switch does nothing and the unit is plugged in, test the outlet. A tripped GFCI upstream can silently kill power to the sink base.

For repeated odors, licensed plumber garbage disposal pull the splash guard and soak it in a mild bleach solution, then rinse and reinstall. If smells persist with a clean garbage disposal seal replacement guard, the issue may be in the dishwasher branch or deeper in the drain. That’s a sign to schedule Kitchen disposal repair Houston service along with a drain inspection.

Brands, warranties, and service life

Most mainstream brands perform well when sized correctly and installed cleanly. Service life tends to run 8 to 12 years in average conditions. Stainless internal components tilt toward the high end of that range, galvanized toward the lower. Warranty terms vary from 1 to 10 years, often split between parts and in-home service. Read the fine print. Some warranties require professional installation to be valid. Keeping the purchase receipt and installation date handy makes any future claim smoother.

I’ve seen budget disposals last a decade in a single-occupant condo and premium models replaced in four years in a bustling household that grinds everything under the sun. Usage patterns matter as much as hardware. Choose the right size, treat it well, and it will quietly do its job for years.

Environmental considerations and Houston’s infrastructure

Disposals and sewer systems aren’t enemies, but they need cooperation. Disposals do not liquefy food; they reduce it to small particles. In a healthy, well-vented drain with proper slope, those particles move along. Problems arise when grease coats the pipe or when the trap and arm are assembled with improper pitch. During flood events, some neighborhoods see slower drainage. If you notice persistent slow flow after storms, a camera inspection of the line can reveal offsets or intrusions that won’t be solved by a new disposal.

On the waste side, diverting heavy, fibrous scraps to the trash or a compost bin helps the disposal handle the nearby garbage disposal technician rest without strain. That habit reduces the need for frequent service and keeps the city’s infrastructure happier.

When you need a pro

Tackling a like-for-like replacement is within reach for capable DIYers, especially where a plug-in cord and clean drain geometry already exist. Call for professional Garbage disposal installation Houston service when any of the following pop up: you need to add or modify a switched outlet, the trap arm sits higher than the disposal outlet, the sink is a new composite or farmhouse model that needs a special flange, or you’ve had repeated leaks around the mount. Also call if there’s any sign of a venting problem, like persistent gurgling or sewer odor. Those point beyond the disposal.

If your main aim is to save the existing unit and you’re looking for Affordable Garbage disposal repair, be clear on symptoms. Share noise level changes, leak locations, and any tripped breakers. Photos under the sink help a technician bring the right parts the first time, which keeps costs down and avoids second visits.

Final perspective from the field

The best disposal installs I see blend two qualities: a clean mechanical fit and respect for the broader system. The unit is aligned and quiet, the trap has proper slope, the dishwasher connection is looped high, and the electrical is safe. No heroics, just disciplined steps. Most failures trace back to skipping one of those basics.

Houston kitchens are varied. From townhomes in Midtown to ranch houses in Meyerland, the cabinets, pipes, and wiring tell their own stories. A pro who reads that story and adapts the plan gives you a disposal that disappears into the background of your life, which is exactly where it belongs. Whether you’re scheduling a first-time installation, lining up Kitchen disposal repair Houston to handle a persistent drip, or deciding between repair and replacement, a grounded approach beats guesswork every time.

DYZ Plumbing, LLC

Address: 1220 Blalock Rd, Houston, TX 77055

Phone: (832) 877-9600