Tackling Hydrogen Cracking: flux oven Practices That Actually Work

Key Takeaways

- Keeping an eye on surroundings is crucial for success.

- Proper after-welding techniques are essential for quality.

- Training and expertise among staff play a vital role.

- Common myths surrounding flux ovens can mislead practices.

- Identifying and resolving hydrogen cracking problems is key.

Monitoring Environmental Conditions

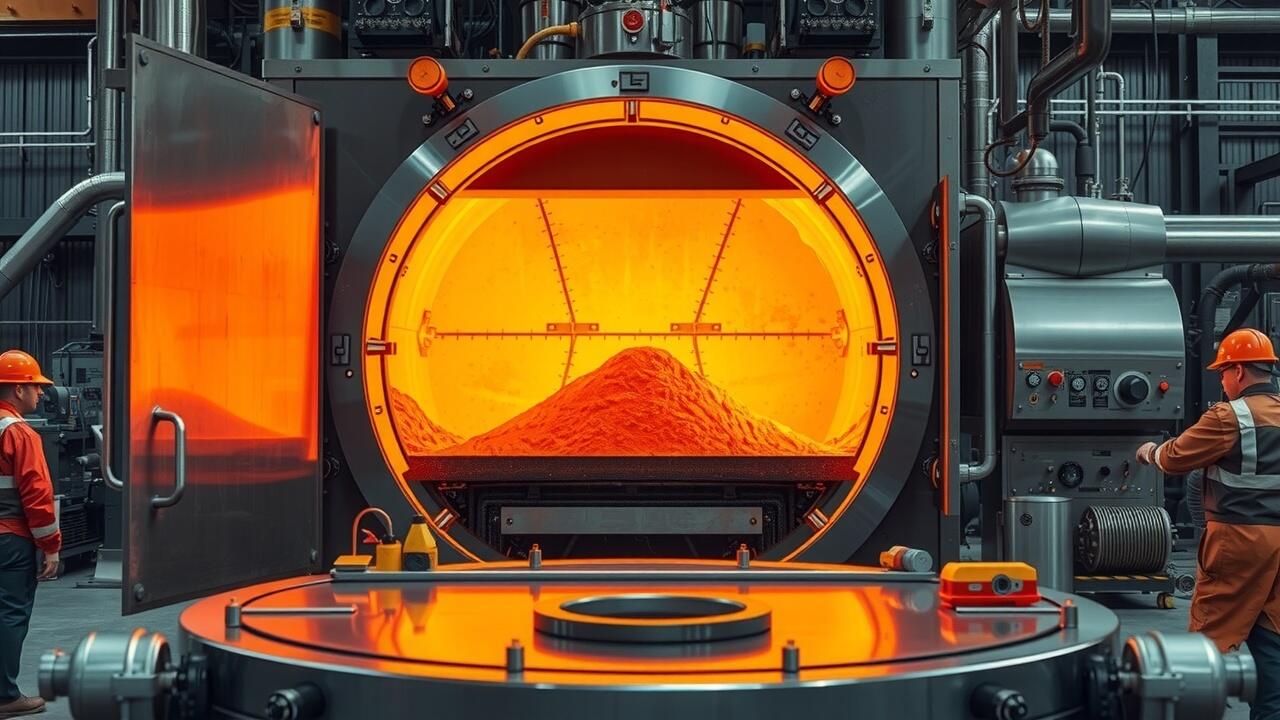

Maintaining the right environmental conditions during welding operations can significantly influence the likelihood of hydrogen cracking. Humidity levels play a pivotal role here. For instance, welding in a high-humidity environment can lead to an increase in moisture absorption by the flux, which in turn raises the hydrogen content in the weld pool. This often results in severe cracking issues. According to the American Welding Society, keeping humidity below 70% is crucial for successful outcomes. Utilizing a welding flux oven not only aids in drying out the flux but also helps maintain an ideal working environment, minimizing the chances of hydrogen-related defects.

Temperature fluctuations also warrant attention. Welding at excessively low temperatures can compromise the mechanical properties of certain materials. For example, when operating in environments below 32°F (0°C), the risk of hydrogen cracking increases, particularly in high-strength steels. Ensuring your flux holding oven is calibrated correctly to maintain a stable environment can make all the difference. Regular monitoring and adjusting of both humidity and temperature conditions can significantly enhance welding quality. Implementing these best practices can help reduce downtime, improve productivity, and lead to stronger, more durable welds.

How Can Humidity Levels Affect Welding Outcomes? (relationship between humidity and cracking)

Humidity plays a critical role in the welding process. When moisture levels rise, particularly above 70%, the risk of hydrogen cracking increases significantly. For instance, a study highlighted that welding under high-humidity conditions led to crack occurrences in 43% of tested samples, demonstrating how environmental factors directly impact structural integrity. When utilizing a flux oven, ensuring the welding flux remains dry is paramount since moisture absorption can lead to the formation of hydrogen during the welding process, potentially resulting in defects.

To counteract the adverse effects of humidity, maintaining proper storage conditions for welding flux in a flux holding oven is essential. Keeping flux at optimal temperatures and humidity levels ensures it retains its efficacy. Moreover, welders should be trained to understand that even slight variations in humidity can alter the chemical reactions during welding, leading to unexpected outcomes. Monitoring environmental conditions should become a routine practice to minimize the chances of hydrogen-related issues.

Effective Post-Welding Practices

Immediate attention after welding is essential for maintaining structural integrity. Conducting a visual inspection right after the welding process can greatly reduce the risk of hydrogen cracking. For instance, implementing a routine where welders routinely check for superficial defects, like cracks or undercutting, allows for quick identification of potential issues. Adhering to AWS D1.1 standards, operators should inspect their work within the first hour after completion, as this timeframe fosters immediate corrective actions before the component is painted or subjected to further processing.

Utilizing the proper equipment can enhance post-welding evaluations significantly. A welding flux oven, specifically designed for maintaining optimal flux conditions, ensures that all welding consumables meet quality protocols. A case study in a recent fabrication shop illustrated that transitioning to a dedicated flux holding oven increased defect detection rates by 25%. This change not only improved the final product but also reduced rework time by half. Thus, creating a streamlined inspection routine, combined with well-maintained equipment, is key to effectively addressing any future hydrogen cracking concerns.

Why Is Immediate Inspection Crucial? (importance of detecting defects early)

Immediate inspection of welded structures ensures that defects are caught early, significantly reducing the risk of hydrogen cracking. When welders complete a joint, they should promptly assess the weld area for any signs of cracks or porosity. Studies indicate that inspecting within the first hour post-welding allows for a 70% higher success rate in detecting issues that might develop later on. This proactive approach minimizes repairs and enhances the reliability of the final product.

Another benefit of early detection relates to the conditions under which the weld was executed. For instance, if humidity levels were high during welding, this could lead to increased moisture absorption by the flux within the flux oven. Given that absorbed moisture can exacerbate cracking, checking the weld immediately is crucial to prevent potential failures. Implementing a routine inspection protocol after welding is not simply about quality assurance; it embodies an essential practice that contributes to the longevity and safety of the welded assembly.

Employee Training and Knowledge

Understanding the challenges posed by hydrogen cracking requires a solid foundation of knowledge among welders. Training should focus on the specific parameters that influence cracking, such as the moisture content in the atmosphere and the proper use of a flux hopper. For instance, welders need to understand how various types of welding flux, like that from a welding flux oven, can absorb humidity and affect their project outcomes. Case studies indicate that welders who have undergone focused training on the relationship between environmental conditions and hydrogen-induced cracking see a significant reduction in defects, with incidents dropping by as much as 15% in some manufacturing settings.

Real-world scenarios often highlight the need for better training programs. For example, a company that switched to dedicated flux holding ovens for their welding processes reported a noticeable improvement in weld integrity after teaching employees about the careful management of flux exposure. Hints on best practices in handling and storing flux, not only maximizes its effectiveness but minimizes the risk of hydrogen cracking. By integrating hands-on training sessions weaving in these practical insights, organizations can ensure that their workforce is equipped with the skills necessary to mitigate risks associated with hydrogen-induced issues.

What Should Welders Know About Hydrogen Cracking? (key training topics and insights)

Understanding hydrogen cracking is essential for welders to ensure quality and safety in their work. One key topic involves the temperature control of the flux oven. Maintaining the correct temperature is crucial, as too high a temperature can cause excessive moisture loss from the flux, while too low can lead to insufficient drying. For example, many manufacturers recommend keeping their welding flux oven between 250°F to 300°F to achieve optimal moisture levels. Proper management of the flux hopper also plays a vital role; it helps prevent moisture absorption of the flux before it even reaches the welding arc.

Another important aspect is the awareness of preheating practices. Preheating the base material effectively reduces the risk of cracking by lowering the cooling rates during subsequent weld passes. Industry studies suggest that steels with higher carbon content, such as a carbon equivalent over 0.40, should be preheated to temperatures above 300°F. This strategy allows the material to handle thermal stresses more effectively, reducing the potential for hydrogen cracking significantly. Welders must incorporate these best practices to bolster their skills and successfully mitigate risks associated with hydrogen cracking, leading to safer and more efficient welding operations.

3 Common Misconceptions About Flux Ovens

Many believe that all flux ovens operate on the same principles. This misconception can lead to improper usage, especially when considering equipment like a welding flux oven versus a flux holding oven. Each type has distinct parameters that affect performance; for example, a saw flux oven specifically maintains lower temperatures for the flux to prolong its life, while a welding flux oven needs to operate at higher temperatures for optimal reactions during the welding process. Knowing these differences can directly impact the quality of welds and the likelihood of hydrogen cracking.

Another common misunderstanding revolves around the necessity of maintaining the flux hopper. Some believe it can just be filled up and left alone, but proper management is crucial. The flux must be kept dry to avoid moisture absorption, which increases the risk of hydrogen cracking during the welding process. Regular checks and maintenance can prevent excess moisture buildup. Including this practice in employee training not only helps in achieving better weld integrity but also minimizes rework and material waste.

How Do These Misconceptions Impact Welding Practices? (clarifying common misunderstandings)

Misunderstandings about flux ovens can lead to significant issues during welding processes. For instance, many welders believe that a flux oven only needs to maintain a specific temperature to ensure quality. However, it’s equally crucial to monitor the moisture levels in the flux hopper. One study found that overly humid conditions can increase the likelihood of hydrogen-induced cracks, resulting in costly repairs and project delays. Proper calibration of the flux holding oven, alongside regular maintenance checks, can help mitigate these risks.

Another misconception is that all types of flux are created equal. Some materials might be more susceptible to hydrogen absorption than others. If a welder uses a less appropriate type of welding flux oven for specific applications, the chances of encountering defects increase significantly. It's essential for teams to understand the compatibility of their flux with the materials they are welding. Training sessions that focus on these nuances can lead to better-quality workmanship and reduced instances of hydrogen cracking.

Troubleshooting Hydrogen Cracking Issues

Hydrogen cracking can be a persistent headache for welders if not addressed correctly. A common troubleshooting step involves examining the use of flux ovens. Ensuring your welding flux oven maintains the right temperature is crucial. For instance, the ideal range for many flux types hovers around 180°F to 200°F, depending on the manufacturer’s specifications. If the temperature dips too low, moisture can become trapped within the flux, leading to the dreaded hydrogen presence in welds.

Another area to consider is the care of your flux hopper. Ensure it's clean, dry, and properly sealed to prevent contamination. Inspect the flux holding oven for any irregularities before beginning work. These small details can often make a noticeable difference. Regularly updating your equipment and adhering to maintenance schedules helps in identifying issues early. By staying vigilant, welders can shield their work from hydrogen cracking while enhancing overall quality.

FAQS

What is hydrogen cracking, and why is it a concern in welding?

Hydrogen cracking is a type of failure that occurs when hydrogen diffuses into the weld and causes cracks to form, typically during or after the welding process. It’s a big concern because it can compromise the integrity of the weld and lead to structural failures.

How does humidity affect my welding outcomes?

Humidity plays a significant role in welding because high moisture levels can increase the amount of hydrogen present, which can lead to cracking. Keeping an eye on environmental conditions is crucial for achieving quality welds.

Why is it important to inspect welds immediately after completion?

Immediate inspection is essential because it allows for early detection of defects before they can worsen. Catching issues right away can save time and money on repairs and ensure the overall safety of the structure.

What should I focus on during welder training to prevent hydrogen cracking?

Welders should be trained on the factors contributing to hydrogen cracking, such as material selection, environmental conditions, and proper welding techniques. Understanding these topics can help them make informed decisions while working.

Are there common misconceptions about flux ovens that I should be aware of?

Yes! Some common misconceptions include that all flux ovens operate the same way, or that they’re not necessary if you’re using low-hydrogen electrodes. These misunderstandings can lead to improper use, increasing the risk of cracking and defects in the welds.