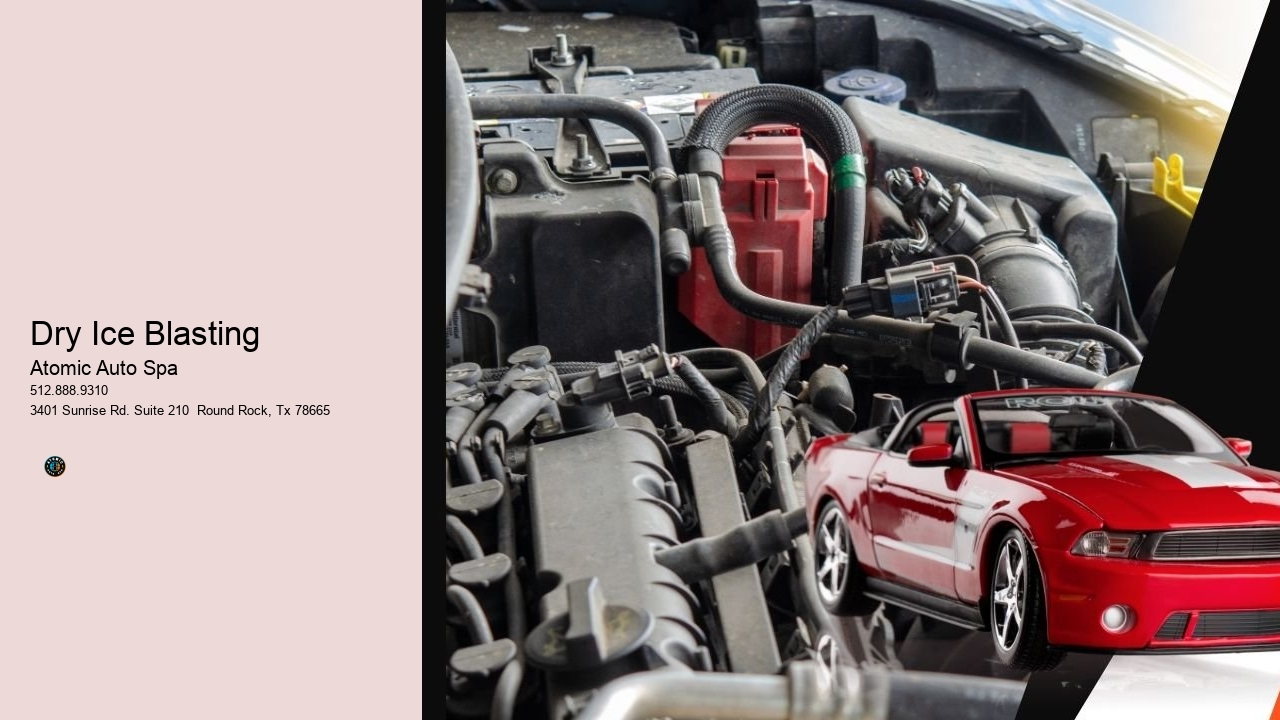

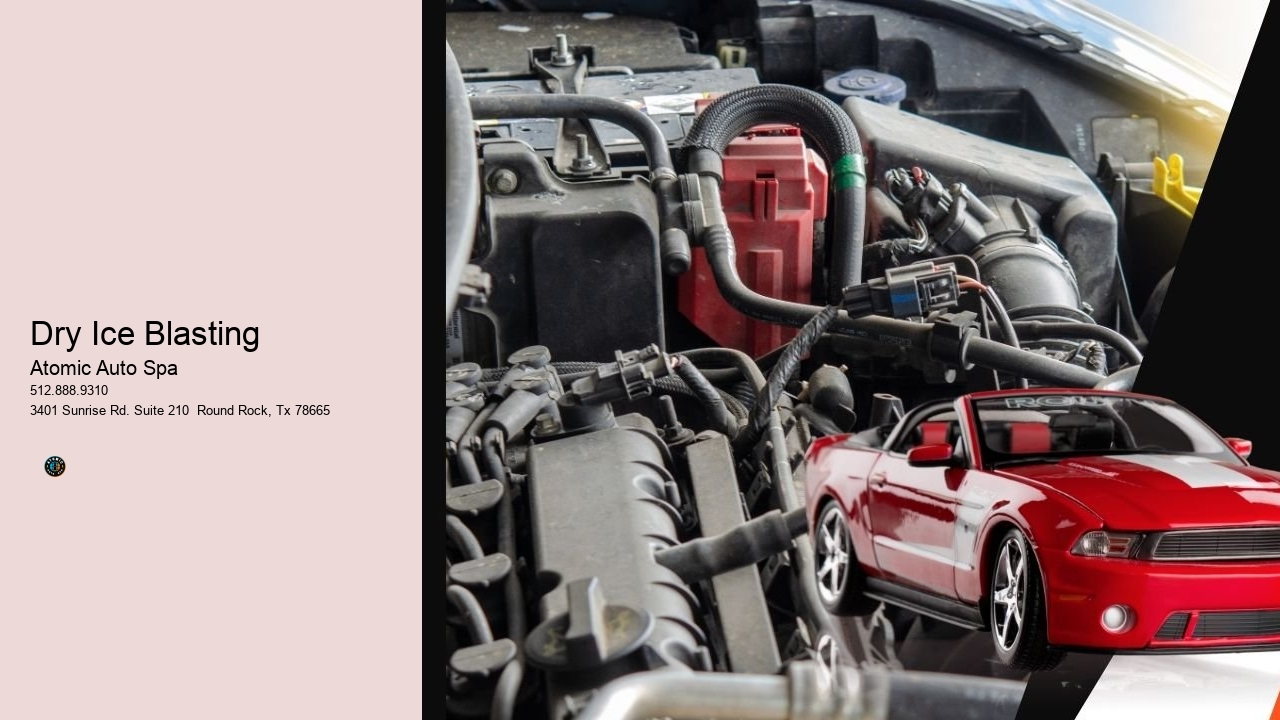

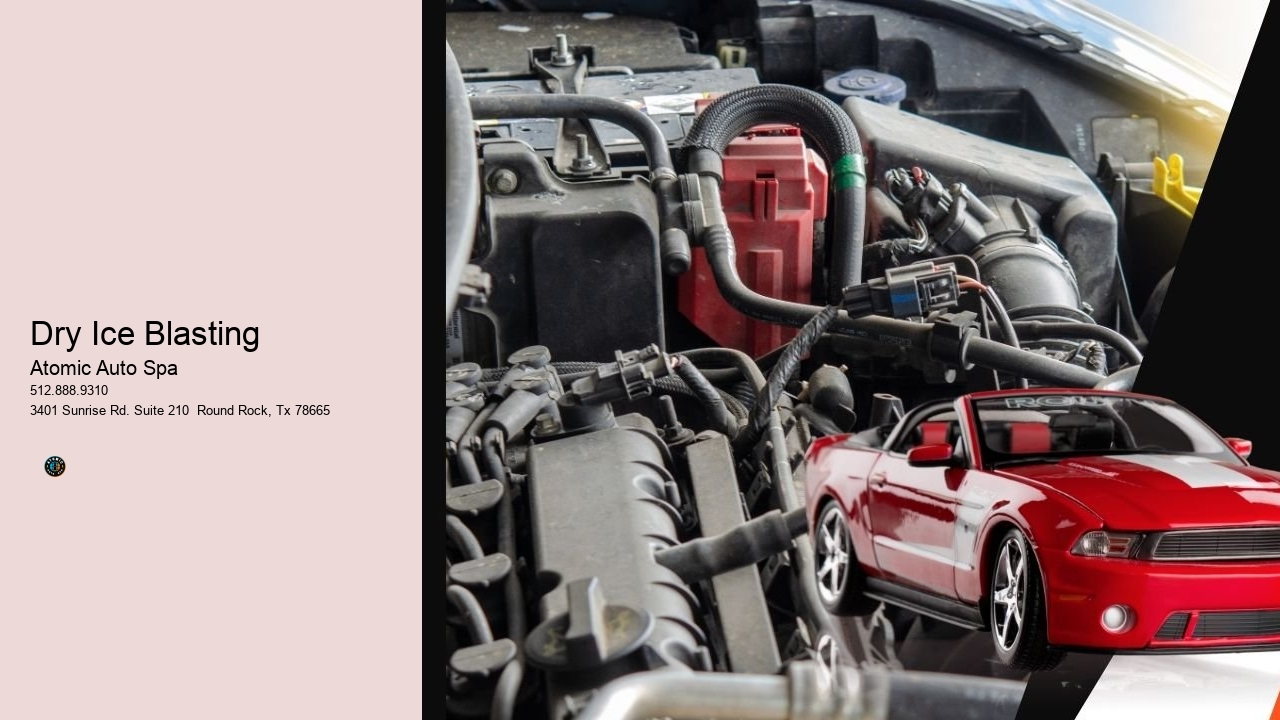

Advanced Dry Ice Cleaning at Atomic Auto Spa

At Atomic Auto Spa, we offer cutting-edge dry ice cleaning—a powerful, non-abrasive method that safely restores a vehicle’s surfaces without moisture, residue, or damage. Unlike traditional cleaning techniques, dry ice blasting effectively removes dirt, grease, and grime without using harsh chemicals or water.

This process is ideal for cleaning engines, undercarriages, and delicate interior components. It reaches tight spaces, lifting contaminants while preserving the integrity of the surface. Classic cars, high-performance vehicles, and daily drivers all benefit from this advanced technique, leaving parts looking factory-fresh without unnecessary wear.

Atomic Auto Spa takes pride in precision and quality, using the latest technology to give vehicles the attention they deserve. Dry ice cleaning is an innovative solution for maintaining or restoring a car without the downsides of traditional methods.

Contact Atomic Auto Spa today to experience the benefits of dry ice cleaning firsthand.

Atomic Auto Spa

3401 Sunrise Rd. Suite 210 Round Rock, Tx 78665

512.888.9310

Dry ice blasting is an innovative cleaning method that utilizes solid carbon dioxide (CO2), commonly known as dry ice, as the primary cleaning medium. Unlike traditional water-based cleaning methods, it leverages the sublimation of dry ice pellets upon contact with the surface to be cleaned. This process lifts dirt and contaminants without producing secondary waste, since the dry ice simply transitions into a gaseous state leaving behind no residues.

One of the most significant benefits of dry ice blasting is its lack of reliance on water. This makes it ideal for use in environments where moisture can cause harm or create additional hazards, such as electrical applications or in food processing facilities. Not using water also means there is no need for drying time, which can greatly reduce overall maintenance and downtime.

The eco-friendliness of this technique stems from several factors. Firstly, dry ice is made from reclaimed CO2 that would otherwise be released into the atmosphere, giving it a smaller carbon footprint compared to other cleaning agents. Secondly, it eliminates the need for chemical solvents that can be harmful to both users and the environment. Lastly, because there's no liquid runoff, there's less risk of contaminating water sources.

Dry ice blasting is non-toxic and does not involve any hazardous chemicals or fumes. This makes for a safer work environment for operators and anyone else within close proximity to the cleaning process. Furthermore, by avoiding chemical cleaners and detergents, there's reduced potential for allergic reactions or respiratory issues often associated with volatile organic compounds (VOCs).

This method has broad applicability across various industries including automotive, aerospace, industrial machinery, electronics manufacturing and more due to its effectiveness at removing contaminants like grease, oil, adhesives and paint without abrasion to the underlying surface. It’s particularly effective in Paint Protection Film (PPF) maintenance where gentle yet thorough cleaning is essential.

While initial setup costs might be higher than traditional methods due to specialized equipment needs; over time dry ice blasting proves cost-effective due to reduced labor hours needed for clean-up after its use – eliminating steps like collecting used media or dealing with wastewater disposal. Moreover, because it doesn't degrade surfaces over time like abrasive techniques do; assets last longer reducing replacement costs.

As industries continue seeking ways to minimize environmental impact while maintaining high standards of cleanliness and efficiency; dry ice blasting stands out as a forward-thinking solution. Its integration into regular maintenance regimens offers a sustainable approach that aligns with increasingly stringent environmental regulations while providing superior results.

View Dry Ice cleaning Round Rock in a full screen map

https://www.atomicautospa.com/blog/how-dry-ice-cleaning-can-transform-engine-bay-detailing

| Entity | Definition |

|---|---|

| Dry Ice Shot Blasting | A cleaning process that uses dry ice at high velocity to remove surface contaminants. |

| Dry Ice Abrasive Blasting | A more aggressive form of dry ice cleaning used for industrial and automotive applications. |

| Dry Ice Pressure Washer | A pressure cleaning system that integrates dry ice for a powerful yet non-abrasive cleaning process. |

| Dry Ice Pressure Cleaner | A high-pressure dry ice machine used for deep cleaning without damaging surfaces. |

| CO₂ Blasting | Another term for dry ice blasting, referring to the use of solid carbon dioxide for cleaning. |

Dry ice cleaning, also known as dry ice blasting, utilizes solid carbon dioxide (CO2) pellets. These pellets are propelled at high speeds onto surfaces to be cleaned through pressurized air streams. Upon impact, the dry ice sublimates—turning directly from a solid to a gas without passing through a liquid phase—and lifts dirt and contaminants off the surface. This process is non-abrasive and non-conductive, making it an innovative solution for delicate tasks such as cleaning intricate car components.

In the realm of automotive care, particularly concerning paint protection films (PPF), dry ice cleaning offers a gentle yet effective means of removing contaminants without damaging the underlying surface. It can be safely used on various materials found within car interiors as well, such as fabrics and electronics. Due to its non-toxic nature and absence of secondary waste products like water or chemicals, it's considered an environmentally friendly method that aligns with the meticulous requirements of maintaining both the aesthetic and functional aspects of vehicle paintwork and interiors.

When considering the application of dry ice cleaning for car exteriors and paint jobs, it's essential to assess its safety and compatibility with the vehicle's surface. Dry ice blasting utilizes solid carbon dioxide pellets that sublimate upon contact, lifting dirt without leaving moisture behind. This method is generally safe for a variety of surfaces, including those protected by paint protection film (PPF). It’s non-abrasive nature ensures that it does not damage the high-quality finishes or intricate designs often found on vehicles. However, caution must be exercised as improper use can lead to thermal shock in certain materials due to the extremely low temperatures of dry ice. For optimal results and preservation of your vehicle's aesthetic integrity, professional execution by experienced technicians is recommended to ensure that pressure settings are appropriately adjusted and no harm comes to your car’s exterior or underlying PPF layer.

Dry ice cleaning, also known as CO2 blasting, is a method that utilizes small pellets of frozen carbon dioxide. It's a non-abrasive technique which makes it a safe option for delicate surfaces within your car's interior. This process can effectively remove dirt and grime without the risk of scratching or damaging upholstery, plastics, or leather.

One of the significant benefits of dry ice cleaning is that it involves no chemicals or detergents. This means there's no residue left behind that might harm your car’s interior materials or present health risks to occupants. For individuals with allergies or sensitivities to chemicals, this presents an appealing advantage.

Because dry ice sublimates upon contact — turning directly from a solid to a gas — it leaves behind no moisture. This is particularly beneficial for electronic components and areas prone to moisture damage. However, some interior materials may be sensitive to extreme cold or rapid temperature changes, potentially causing issues if not properly assessed before application.

Dry ice cleaning is environmentally friendly since it produces no secondary waste; this aligns well with the maintenance of cars fitted with paint protection film (PPF). The absence of abrasive particles ensures that PPF remains intact during the cleaning process, preserving its protective qualities and finish.

While dry ice cleaning offers many benefits for car interiors, proper technique and handling are crucial due to the potential hazards associated with carbon dioxide exposure and handling extremely cold substances. It is generally recommended that this type of cleaning be performed by professionals who understand how to safely manage the risks while optimizing the benefits for vehicle sanitation and maintenance.

Before proceeding with dry ice cleaning, it’s crucial to meticulously inspect the vehicle's surface and interior. Identify areas with paint protection film (PPF) and ensure that its edges are well-sealed to prevent moisture from penetrating underneath. For the interior, focus on assessing materials that could be sensitive to extreme cold or rapid temperature changes, such as leather or soft plastics.

Employ a high-quality dry ice blaster explicitly designed for automotive use, which allows for precise control over the pressure and size of the ice particles. This ensures that you can adjust the intensity of cleaning to suit different surfaces without damaging the PPF or car paint. Protective nozzles should be used when working near delicate areas to safeguard against accidental abrasion.

Technique is paramount in preventing potential damage. Maintain a consistent distance and angle while blasting; this avoids concentrating the cold blast in one spot, which could lead to cracking or delamination of PPF. Additionally, keep motion steady and avoid lingering over seams or intricate designs where PPF might end, ensuring an even clean without compromising the integrity of the vehicle’s aesthetic details.

Automotive, aerospace, food processing, manufacturing, and restoration industries use it for deep cleaning.

Yes, it is gentle and safe for high-end and vintage vehicles.

Search for specialized automotive and industrial cleaning services in your area.