Houston Garbage Disposal Installation: Choosing the Right Unit

A good garbage disposal turns a busy Houston kitchen into a smoother, quieter operation. Pick the wrong unit and you inherit noise, jams, sewer odors, and the kind of vibration that loosens plumbing joints. Pick well and you barely notice it is there, even when it is chewing through last night’s fajita trimmings. This guide draws on what actually matters in Houston homes: water chemistry, slab foundations, a mix of older and new-construction kitchens, and Gulf humidity that tests seals and metal parts. If you are thinking about a first-time install or an upgrade, or you are just trying to decide whether a repair makes more sense than replacement, you will find the trade-offs here, not the marketing gloss.

What “right” looks like for Houston kitchens

Homes across Greater Houston vary wildly, from post-war bungalows in the Heights to new builds in Katy with deep sink bays and islands wired for modern appliances. The best disposal for a 700-square-foot garden apartment is not the same as the best for a five-bedroom house with a family that cooks nightly. The right match comes down to a few variables: motor size, grinding technology, noise control, fit under the sink, and how the unit plays with your plumbing and local rules.

I have replaced disposals that lasted 18 years, and I have replaced disposals that died in three after improper installation left them vibrating themselves to death. The brand matters less than matching power and features to how you cook, the type of sink you own, and how often the unit will run. If you rarely cook and mostly rinse plates, you can save money with a smaller, lighter unit. If you run a big household that hosts gumbo Sundays, step up the power and sound insulation.

Motor power, realistically

Manufacturers advertise horsepower like car makers sell trim packages. Ignore the gloss and think about the load.

-

For a light-use kitchen with one or two people, a 1/3 or 1/2 HP unit can work, but only if you are careful. Eggshells, fibrous vegetables, and stringy chicken skin will challenge these motors. Expect more jams, and expect to use the hex key under the sink a few times a year.

-

For average families that cook 3 to 5 nights a week, 3/4 HP hits the sweet spot. It drives a heavier grind chamber and handles most leftovers without fuss. Many of these units add better sound insulation and stainless steel components, both of which pay off in Houston’s humidity.

-

For heavy cooks, big families, or anyone who values quiet and speed, 1 HP or higher offers margin. These units chew through dense scraps like melon rinds and small bones, and they run smoother. If your sink drains slowly or your P-trap is slightly out of alignment, the extra torque helps power through minor resistance.

I keep a mental note from service calls: the majority of persistent clog calls I see come from 1/2 HP units fed like they were 3/4 or 1 HP. If your habits outrun the hardware, the unit will let you know.

Continuous feed vs. batch feed

Most Houston kitchens use continuous-feed disposals. You flip a switch and feed scraps while it runs. It is fast, convenient, and cheap to install. Batch-feed units grind only when a magnetic stopper is in place. They tend disposal impeller replacement to be quieter and add a layer of safety if curious kids like to explore the sink. They also solve one Houston-specific issue: accidental activation from a worn wall switch in humid conditions. The trade-off is cost and inconvenience if you are in a hurry. If you are already budgeting for a premium 1 HP unit and you have kids, batch feed is worth a look.

Noise matters more than you think

A loud disposal does not seem like a big deal until you have people gathered around the kitchen. Sound ratings vary, and the marketing terms are squishy. Look for units that list layered insulation, anti-vibration sink mounts, and balanced impellers. A 1 HP model with good insulation often sounds calmer than a cheaper 1/2 HP model. If your sink is a thin-gauge stainless bowl, expect more noise. Thicker sinks dampen sound better. Undermount granite or quartz with a heavier basin makes even a mid-range unit sound civilized.

A trick from the field: if your disposal sounds like a jackhammer, check the mounting ring and the support flange. If the installer did not torque the mounting screws evenly, the unit will rattle and amplify sound. I have reduced noise drastically by simply realigning and tightening a properly insulated unit.

Materials and Houston’s humidity

Stainless steel grind chambers hold up better in our climate than galvanized steel. Houston’s humidity and water chemistry encourage corrosion, especially if the unit sits unused for long stretches. Stainless components resist both rust and pitting, which preserves balance in the moving parts. That balance means fewer vibrations, which means longer life for seals and couplers.

Rubber components deserve attention too. The splash guard under the sink flange dries out and cracks faster in homes that run the unit rarely. Plan to replace that baffle every few years. If you catch sewer odors near the sink, the splash guard is often the culprit, not the unit itself.

Size, weight, and the under-sink reality

Clearance under Houston sinks varies. Some homes have deep farm sinks with tall disposals installed over tight P-traps. Others have RO filters, pull-out trash bins, or elaborate water softener loops competing for space. A 1 HP disposal can be bulky and heavy. If the cabinet floor has any sag from past leaks, that weight matters. I have shored up more than one bottom panel with marine plywood and a bead of construction adhesive to keep a heavy unit from drifting out of alignment. Before you commit to the larger model, measure height from the sink drain to the cabinet floor, note the position of the trap arm in the wall, and make sure the unit will not force your trap into a slope that invites clogs.

If you are swapping a builder-grade disposal for a premium unit, be ready to rework the discharge tube and sometimes the trap. A small change in outlet height can set you up for standing water in the chamber, which breeds odor and corrosion.

Electrical and switch choices

Most disposals in the area run on a standard 120V circuit. Some come with a factory cord and plug into an outlet under the sink. Others ship bare and need to be hardwired. If you have a dishwasher sharing the same junction box, keep the connections neat and use proper strain reliefs. Houston’s humidity finds any exposed copper. A plug-in cord is easier for future swaps and makes quick troubleshooting safer. A hardwired unit looks cleaner and avoids a loose plug that can cause intermittent power. Either is acceptable, but follow code and, if you are not sure, bring in a licensed electrician.

Switch location matters. A wall switch near the countertop works, but I have seen accidental activations when kids lean against the backsplash or when older switches arc. An air switch mounted on the countertop gives tactile control and keeps the electrical away from water. If you have a farmhouse sink with a narrow deck, check clearance for the air switch button before drilling.

Dishwasher tie-ins and the knockout plug

If your dishwasher drains through the disposal, you must remove the knockout plug on the disposal’s dishwasher inlet before installation. Miss this step and your dishwasher will flood the cabinet on its first cycle. I have taken too many calls labeled “dishwasher not draining” that turned out to be an unremoved plug in a brand-new disposal. After removing the plug, run a short length of high loop on the dishwasher hose before connecting to the inlet. It reduces backflow and soap scum buildup in the disposal throat.

Plumbing compatibility and Houston-specific quirks

Many homes in the city use 1.5-inch ABS or PVC traps, but older houses may still have cast iron or copper. When installing a new disposal, watch for mismatched trap heights and brittle trap arms. If the trap connects into a cast iron tee in the wall with a slip joint that has seen better days, be gentle. A small twist can crack an old ferrule and leave you with a slow, hidden leak.

If you live in a flood-prone area and have had any foundation movement, check that the sink drain line still has proper slope. A disposal that drains into a slightly uphill trap will back up grease and ground food and will clog more frequently. Minor realignment with a new trap kit can cure what looks like a disposal issue.

Septic systems, municipal guidance, and what Houston allows

Most Houston service areas use municipal sewer, and disposals are allowed. If you are on a septic system outside the main grid, ask your service provider before you install. Some septic systems can handle a disposal if you size the tank correctly and pump on schedule. That said, sending extra solids and fats to a septic tank shortens the interval between pump-outs and can upset the bacterial balance. If you are on septic and you still want a disposal, choose a unit with multi-stage grinding for finer particles, and commit to strict habits about what you send down.

What not to feed a disposal

Marketing often shows disposals chewing everything, but prevention beats repair. I have pulled out the same villains across neighborhoods:

- Large quantities of fibrous vegetables like celery, artichokes, and collard stems. Small amounts are fine with water running, but a handful can mat and jam the grinding plate.

- Fats, oils, and grease. A tablespoon here and there will not ruin the unit, yet repeated dumps line the pipes with sticky residue that catches everything else.

- Coffee grounds. They feel harmless, but they settle like sand in P-traps and clean-out tees, especially in older cast iron lines.

- Eggshells and nutshells in volume. The occasional shell cleans the splash guard, but a dozen shells at once add grit and fill the trap.

- Stringy poultry skin and membrane. It wraps the grinder like fishing line on a prop.

This is the first of only two lists in this article, kept short because the principle is straightforward: feed small, run water, and do not treat the unit like a trash can.

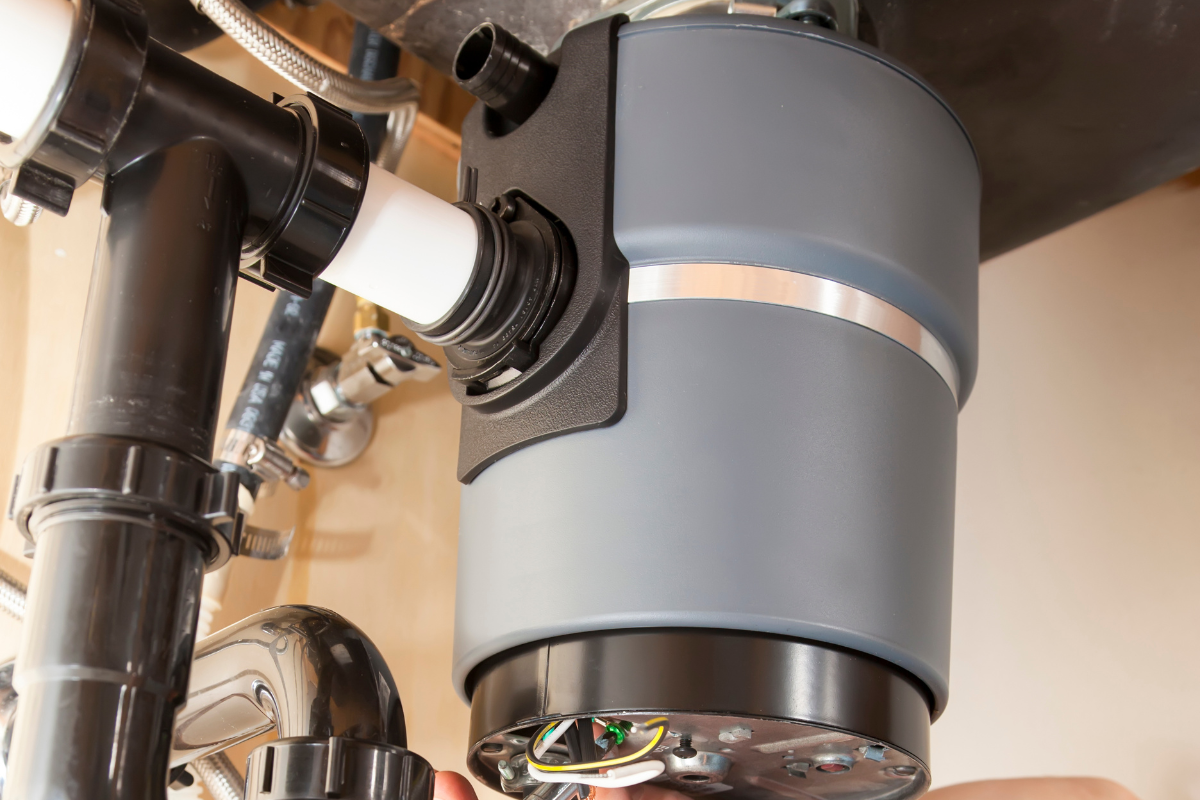

Installation: what a clean job looks like

You will find thousands of videos showing disposal installs that skip steps or take shortcuts that do not hold up in Houston conditions. A clean install follows a rhythm. First, the sink flange must seat with the right sealant. Plumbers argue about plumber’s putty versus silicone. On stainless steel sinks, I prefer a high-quality, non-staining putty that stays workable in heat. On natural stone or composite sinks, silicone or a putty rated safe for stone prevents oil staining. The flange should be pressed and torqued evenly, allowing the sealant to squeeze out in a uniform bead. Wipe clean, then let gravity and time set the seal for at least an hour before hanging the unit if the sink is thin or flexes.

Second, wiring should be secured in a junction box or routed to a GFCI-protected receptacle where required. Ground connections do not get skipped. I have seen brand-new units that shorted out because someone twisted two wires and taped them in the dark corner under a sink.

Third, the discharge tube and trap should be aligned with minimal stress. Hand-fit dry, then tighten by hand and give a final quarter-turn with pliers. Over-tightening compression nuts cracks plastic ferrules and creates slow leaks that show up days later as a musty smell.

Fourth, test with colored water and a full sink drain. I keep food coloring tablets in the truck for this. Fill the sink, run the disposal, and check every joint. Colored water makes the smallest leak obvious. Run hot water for two minutes to confirm the unit clears fully and does not leave backwash in the chamber.

When repair makes more sense than replacement

A dead unit does not always mean you need a new one. The most common fix is a jam cleared with the hex key that ships with the disposal. Turn off the breaker, insert the key in the bottom, work it back and forth, then press the red reset button. If the motor hums but will not spin and trips repeatedly, the start capacitor may be failing. On some models, a capacitor swap costs less than a new unit. Leaks from the dishwasher inlet or discharge elbow usually come from loose clamps or cracked gaskets, both cheap parts.

If the unit leaks from the body seam, or the motor windings smell burned after a reset, replacement is smarter. Once a grind chamber pits through or a motor overheats repeatedly, even an affordable repair will not buy you much time. In those cases, look for affordable garbage disposal repair services that give honest assessments. The reputable outfits in Houston will tell you if a small part can save the day, and they will quote a new unit without pressure if the math favors replacement. If you search disposal drain unclogging phrases like “Affordable Garbage disposal repair” or “Kitchen disposal repair houston,” focus on providers who show their license, offer a clear trip fee, and do not bury you in add-ons.

Choosing a brand: reality over loyalty

Two major brands dominate the market with reliable parts availability. Both make entry-level to premium lines. Beyond that, several private-label units mimic mid-tier designs with slight compromises in sound insulation or materials. I rarely steer clients to a specific brand unless they need part compatibility with an existing sink flange or mounting system. In that case, sticking to the same brand makes replacement faster and cheaper.

What matters more than the badge is the assembly quality. Look for stainless grind components, a thick rubber splash guard, clogged kitchen sink repair cast metal mounting rings instead of thin stamped pieces, and a balanced impeller. If you can pick up the unit, heft it. A heavier, well-insulated body generally runs smoother. Confirm the warranty and read the exclusions. Some lifetime corrosion warranties look generous until you notice they exclude labor and shipping, which can exceed the price of a mid-range new unit. For those hiring for garbage disposal installation houston, ask the installer which models they carry on the truck for same-day swap. Common models mean faster service down the line.

Water flow, drain slope, and the myth of “more water fixes everything”

Good water flow helps, but it does not cure bad plumbing geometry. Run a steady cold stream while grinding and for 10 to 20 seconds after the last scraps disappear. Cold water keeps fats solid so they move, but do not overthink the temperature. Hot water is fine for cleaning the sink after you finish grinding. If the trap is too high or nearly flat, you will still get clogs no matter how religiously you run water. In those cases, the fix is a trap repositioning, not a bigger disposal.

Odor control without gimmicks

A healthy disposal should not smell like a swamp. If it does, clean the splash guard. That flexible rubber harbors food film. Pull it up and scrub both sides with dish soap and a stiff brush. Grind a few ice cubes and a small lemon wedge to freshen the chamber. Avoid bleach. It can degrade rubber parts and does nothing for a film deeper in the drain. If the smell returns quickly, you may have a partial clog in the trap or a venting issue pulling sewer gas into the sink. That is a job for a tech who knows the local code and can spot a misrouted vent or a failing AAV on island sinks.

Warranty terms that matter in the real world

Most Houston homeowners replace disposals when they sell, remodel, or when a unit leaks. Making the warranty work for you is less about the headline years and more about ease of service. Motor coverage is common, but labor coverage is rare. If a contractor offers a one-year labor warranty on top of the manufacturer’s parts warranty, that saves you a service call fee if a defect shows early. Keep your invoice and model number. If you later call for Garbage disposal repair, you will avoid guesswork and ensure the tech arrives with compatible parts.

The installation quote: what you should expect to see

A straightforward garbage disposal installation in Houston should detail the model, horsepower, whether it includes an air switch, the type of flange sealant, and any trap reconfiguration. If the job involves wiring a new receptacle, that should be a separate electrical line item. Extra charges that are reasonable: a new P-trap kit if the old one is corroded, a dishwasher branch tailpiece if you are adding a dishwasher connection to a sink that lacks one, and a new flange if the old one is pitted. Unreasonable: vague “materials fees” that add up to a third of the job without specifics. Ask for clarity. Good companies that advertise “Garbage disposal installation houston” will happily itemize and explain.

First-time install vs. replacement

Adding a disposal to a sink that never had one is a different animal than swapping an old unit. You may need:

- A dedicated switch or an air switch kit and a properly grounded receptacle in the cabinet.

- A revised trap and tie-in to accept the disposal’s different outlet height.

- A dishwasher branch, if you plan to share the disposal’s drain inlet.

- A new sink flange compatible with your sink material and thickness.

- A GFCI or AFCI arrangement depending on local code interpretation.

This is the second and final list in this article. For garbage disposal maintenance many homeowners, a first-time install is where hiring a pro pays off. One miscut hole in a quartz counter for an air switch costs more than the entire install.

Trade-offs for rental properties

Landlords often ask for the cheapest unit that will last through turnovers. In rentals where tenants may not be careful about what goes down the drain, a mid-range 3/4 HP with decent stainless parts strikes the balance. Pair it with a clear clause in the lease that tenant-caused blockages are billable. From experience, fewer calls come from units that run quietly and do not vibrate. Tenants tend to notice and shut off the unit when something is wrong if it does not sound like a blender full of screws every time.

Seasonal loads and storm prep

Storm weeks change kitchen habits. More people at home, more cooking, and sometimes power interruptions. If a storm cuts power while the disposal is mid-cycle, it may jam when power returns. Teach the household where the hex key lives and how to reset the unit. Avoid running the disposal during brownouts. Low voltage can overheat the motor. After a flood event, do not run a disposal that has been submerged. Even if it looks fine, the bearings and motor windings may be compromised. That is a replacement, not a repair.

Cost ranges that make sense

In Houston, a basic 1/2 HP installed by a professional often lands in the lower hundreds, depending on access and whether electrical is ready. A quality 3/4 HP with sound insulation typically adds a modest premium. A 1 HP batch-feed model with an air switch and a new trap layout can approach the higher end of residential budgets. Prices swing with fuel, parts supply, and whether you are bundling the work with a dishwasher or sink replacement. If you are quoted a price that seems too good to be true, ask what model number is included and what happens if the installer hits a corroded trap or a mismatched flange. The cheapest quote often grows once the cabinet door opens.

For those trying to stretch dollars, consider calling for “Affordable Garbage disposal repair” first, especially if your unit is under 8 years old and the complaint is a jam or a small leak at a connection. A competent tech can often restore performance for less than half the cost of replacement. If the unit is 10 or more years old and the motor has seen multiple resets, replacement pays off in reliability and quiet.

A quick field anecdote

A homeowner in Meyerland called about a chronic clog after installing a high-end 1 HP unit themselves. The disposal was flawless. The trap arm, however, rose a full inch to meet the wall tee. Every Monday they ground weekend leftovers and then spent Tuesday with a plunger. We reworked the trap to achieve a proper downhill slope, trimmed the discharge tube to remove a belly, and the problem vanished. The point: even the best unit cannot overcome bad geometry. Choosing right includes installing right.

Final checks before you buy

Set a realistic budget that includes installation, and be honest about how you cook. Measure the space under your sink, note existing wiring and dishwasher connections, and peek at the current trap layout. Decide whether you want an air switch. If you are sensitive to noise, prioritize higher insulation. If you run a busy kitchen, favor 3/4 HP or 1 HP with stainless components. If your unit is limping along and you are unsure, a quick call for “Garbage disposal repair” can give you a clear go or no-go. Reliable technicians in “Kitchen disposal repair houston” see these patterns daily and can steer you to a fix or a replacement that fits your kitchen, not just the catalog.

A garbage disposal is small compared to a range or a fridge, yet it sets the tone for how your kitchen feels during cleanup. Choose with your actual habits in mind, install with care, and you will forget it is even there, which is exactly the point.

DYZ Plumbing, LLC

Address: 1220 Blalock Rd, Houston, TX 77055

Phone: (832) 877-9600