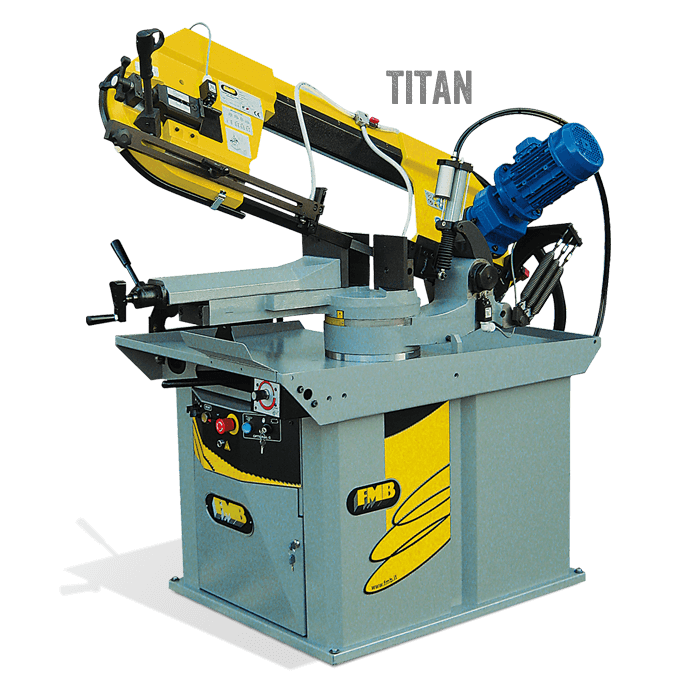

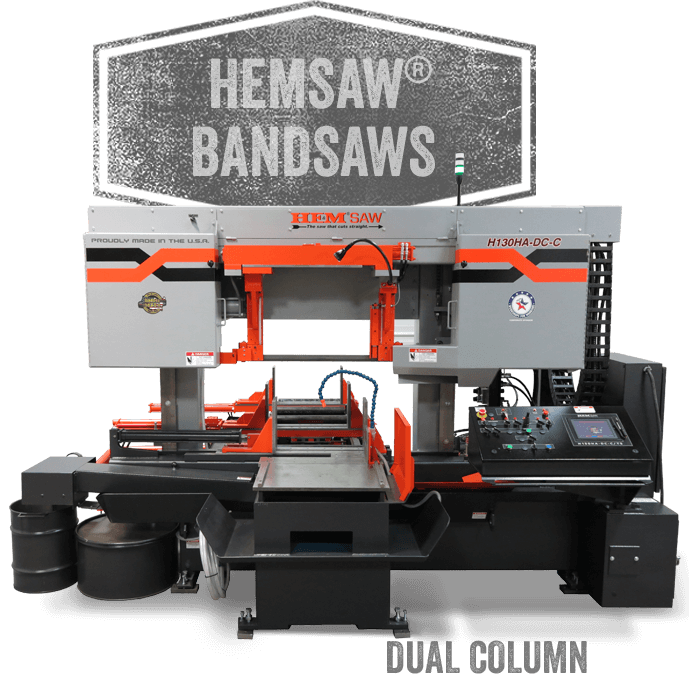

Cnc Band Saw Machine

Swage

To quickly reduce the size of these pieces, you can run them along a miter guide.

The work table is much larger than the 9-in. Bench saws are 12-1/4 inches. It measures 11-7/8 inches x 11-7/8 inches and can be beveled up to 45 degrees. The band saw has a 2-1/2-in. It comes with a 2-year warranty and dust port.

Cnc Band Saw Machine