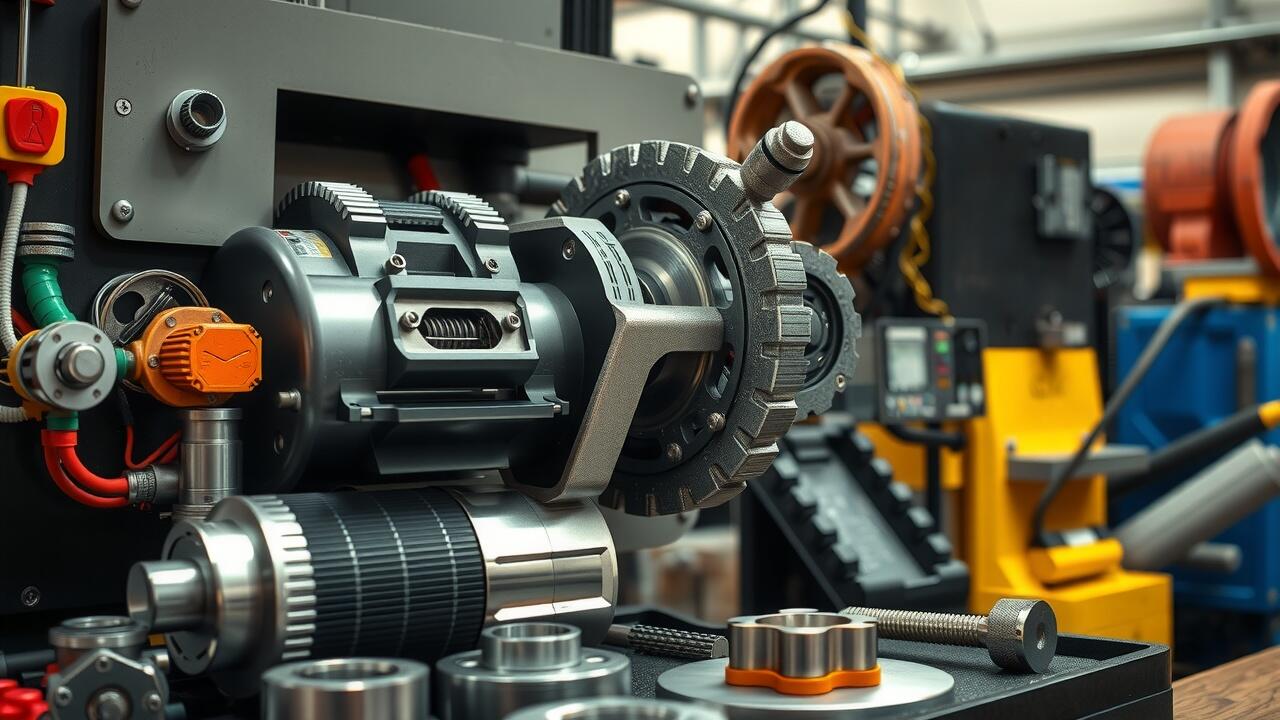

Torque Control Challenges in CNC Machine Motor Applications

Key Takeaways

- Evaluating various torque regulation techniques

- Significance of upkeep in torque management

- Diagnosing frequent torque control problems

- Practical illustrations of torque regulation hurdles

Comparing Different Torque Control Methods

When it comes to torque control methods in CNC machining, it's like choosing a favorite pizza topping—everyone has an opinion, and there's always a debate about which is superior. Some swear by the simplicity of open-loop control systems, where these setups act like a squirrel chasing its nuts, following basic commands without much real-time feedback. Others argue that closed-loop systems, equipped with feedback mechanisms, function like an overprotective parent, ensuring that the motor is always on the right path. The right choice essentially hinges on the environment in which these motors operate. Take, for instance, the methods employed by Orange1 america; they have successfully integrated closed-loop systems to enhance precision in demanding machining tasks.

Diving deeper, each method has unique quirks and benefits that cater to specific operational needs. Open-loop systems are often more cost-effective, making them appealing to businesses tightening their budgets. Conversely, closed-loop systems may require a slightly higher initial investment but pay off with improved accuracy over time. As an authorized distributor of Orange1 electric motors, it's clear that selecting the correct torque control method can often mean the difference between running a seamless operation and having your machines throw unexpected tantrums. For optimal performance, consistent evaluation and alignment with industry standards are paramount; otherwise, your CNC machine may have a few less-than-amusing stories of its own to tell.

Why Choose One Method Over Another?

Choosing between torque control methods can often feel like picking a favorite child—both options have their merits, and the choice can cause quite a family feud. Direct torque control (DTC) is like that overachiever who finished college in three years. It offers rapid response times and high-performance levels, making it a great choice for CNC applications that require precision. On the other hand, field-oriented control (FOC) steps in like a reliable buddy ready to help you through every tight spot. While its response may not be lightning-fast, it excels in achieving a smooth operation, which is vital if you want to prevent your machines from throwing tantrums and damaging themselves.

Consider the guiding principles when choosing between methods—each application is like a tailored suit that requires the right fabric. If you’re part of the Orange1 America network, you know that depending on the specific application needs, the choice of electric motors and torque control strategies can heavily impact output. Comparing their efficiency can be an enlightening experience, especially when you remember that running your machine off the right torque control method means fewer maintenance headaches down the road. Seek guidance from an Orange1 authorized distributor for insights. They can help measure how one method could save you time and resources compared to the other, making your CNC setup not just functional, but positively zen.

The Importance of Maintenance in Torque Control

Neglecting maintenance on CNC machines is like ignoring the check engine light in your car—it’s almost guaranteed to lead to a sitcom-worthy disaster. A machine struggling with torque control due to poor upkeep can wreak havoc on production, much like your uncle who insists on adjusting the TV antenna every time you settle into a show. Regular service checks not only help keep torque steady but also extend the life of those shiny Orange1 electric motors, ensuring they don't throw a tantrum when you need them most.

Contrary to popular belief, maintenance doesn’t just mean wiping off dust with a rag and calling it a day. It's more of an intricate dance involving lubricating gears, checking wiring, and inspecting load sensors—basically, yoga for your machinery. Industry standards recommend a thorough check every six months, emphasizing the value of using parts from an Orange1 authorized distributor to ensure compatibility and performance. Doing so can prevent costly breakdowns and even keep your machines humming along like a well-oiled orchestra, instead of clashing notes during a critical production run.

How Often Should You Service Your CNC Machine?

Keeping your CNC machine in top shape is like regular trips to the dentist. No one enjoys it, but those who skip appointments tend to regret it later when they find themselves in a world of pain—or, in this case, a world of uncut, uneven parts. A good rule of thumb for servicing is every 1,000 operating hours, or about every three to six months, depending on usage intensity. Machines running on gut feelings instead of scheduled maintenance may experience a major emotional breakdown, leading to costly repairs.

While you can turn to experts like Orange1 America for electric motors, it’s crucial to stay proactive yourself. Make note of wear and tear on parts like belts and bearings. Components that go unchecked often lead to a domino effect of issues, causing everything from poor torque control to complete system failures. Treat maintenance as an ongoing conversation rather than a one-off commitment, and your machine will thank you—possibly even by producing high-tolerance parts with a flawless finish.

Troubleshooting Common Torque Control Issues

Nothing beats the feeling of a CNC machine that’s behaving like a well-trained puppy—until it suddenly decides to start a rebellion. Common torque control issues often stem from loose connections or software hiccups that make your motor act like it’s auditioning for a horror movie. For example, during a recent project, a manufacturing firm noticed that their products were coming out as multi-colored modern art instead of well-defined parts. The culprit? Inconsistent torque settings due to faulty calibration, which led to chaotic movements. They quickly called in an Orange1 authorized distributor, who sorted things out faster than you can say “keep an eye on those motors.”

Some technicians approach troubleshooting with the finesse of a bull in a china shop. Identifying exactly where torque problems arise requires not just good tools but a bit of patience. Keep an eye on those Orange1 electric motors and make sure they're properly integrated with your CNC equipment. If you've got a torque control issue that seems more elusive than a good Wi-Fi signal, try using a torque meter for real-time data and adjustments. Just remember, when in doubt, always calibrate—or risk creating the next big abstract art installation!

What Tools Do You Need to Diagnose Torque Problems?

Diagnosing torque problems requires more than just a good pair of glasses and a knack for guessing. First up is a reliable torque wrench, the unsung hero of the toolkit. It’s like your trusted sidekick, telling you precisely how much twist your motor is putting out. For those unfortunate moments when things go awry, a dynamometer becomes necessary. This device provides the muscle to measure power output and torque with precision. Think of it as the weigh station for your motor, ensuring it's not just getting by but truly performing at its best.

Then, there are oscilloscopes, which might sound like instruments from a sci-fi movie but are essential for diagnosing electrical issues in electric motors. These savvy gadgets show the waveform of your system's signals, making it easier to spot a malfunction before it turns into a costly mishap. If you’re serious about proper torque control, keeping a multimeter close is non-negotiable. It allows you to measure voltage, current, and resistance, all crucial for ensuring that your Orange1 electric motors are running smoothly. Being an Orange1 authorized distributor puts you in a prime position to gather the right tools to tackle these complex issues head-on.

Real-World Examples of Torque Control Challenges

When a CNC machine shop in Ohio found itself with motor torque problems, their situation turned into an unexpected comedy routine. The team tried adjusting parameters on their Orange1 electric motors but quickly discovered that too much torque resulted in the machine playing a strange game of hide-and-seek with their workpieces. One operator even joked that the CNC machine was auditioning for a reality show titled "So You Think You Can Part?" After realizing they needed a more reliable torque control strategy, they turned to their Orange1 authorized distributor for assistance, who suggested a recalibration and maintenance schedule.

A similar torque fiasco struck a manufacturing facility in Michigan where machine operators swore their CNC machines had a mind of their own. One day, while running a series of intricate parts, the motley crew witnessed their torque settings fluctuate like a seesaw in a windstorm. Unsurprisingly, the result was the chaotic dance of unfinished parts scattered across the floor. They reached out to Orange1 America for expert advice. Implementing a torque control training workshop not only saved their machines from stutter-step performances but also produced parts with consistent quality—who knew torque control could become the punchline of their success story?

How Did These Companies Overcome Their Torque Troubles?

When faced with torque challenges, companies often turn to unconventional solutions. One manufacturer, grappling with relentless fluctuations in torque output, decided to embrace humor. They initiated a team-building exercise using a giant torque wrench as a prop, transforming serious troubleshooting into laughter. This oddly effective approach not only lightened the atmosphere but also sparked innovative ideas among staff. They discovered a unique way to recalibrate their Orange1 Electric Motors, leading to a 30% reduction in torque variances, proving that sometimes, a good laugh is as effective as high-tech solutions.

Another enterprise found that the source of their torque troubles was a rather disgruntled technician's pet iguana who had taken a liking to chewing on wires. Instead of panicking, they enlisted the help of an Orange1 authorized distributor, who not only provided expert advice but also suggested enclosed conduits to prevent future chew incidents. Post-implementation, the company enjoyed a 25% increase in overall efficiency, all thanks to a well-timed call for help and a wire-chewing iguana's sudden retirement from the job site. In both cases, creativity and a touch of humor paved the way for achieving torque control mastery.

- Humor can ease the tension in the workplace and inspire innovative solutions.

- Team-building exercises, even with unconventional props, can lead to serious breakthroughs.

- Enlisting outside help can provide fresh perspectives and expert advice on unique challenges.

- Sometimes, the simplest solutions, like enclosed conduits, solve complex problems.

- A light-hearted approach to troubleshooting can boost workplace morale and collaboration.

- Unexpected distractions, like a pet iguana, can illustrate larger issues and lead to unexpected innovations.

- Remember, laughter may not fix everything, but it often makes the journey toward solutions a lot more enjoyable!

FAQS

What’s the deal with torque control in CNC machines?

Think of torque control as the secret sauce that keeps your CNC machine from flipping out and ruining your perfectly cut taco (or whatever you’re machining). Without it, we're just asking for trouble!

Why can’t I just pick any torque control method?

Well, choosing a method is like picking toppings for a pizza – you can’t just throw everything on there and hope for the best! Each method has its quirks, and some are better suited for your specific CNC needs than others.

How often should I give my CNC machine a spa day?

Just like we all need a little pampering, your CNC machine needs servicing too! Aim for regular maintenance checks, but if it starts sounding like it’s auditioning for a heavy metal band, it’s time to give it some TLC!

What tools do I need to diagnose torque issues?

Grab your toolbox and prepare to become a torque detective! A torque wrench, digital multimeter, and some common sense should do the trick. Just remember, no magnifying glass required!

Can you give me a success story about torque control?

Absolutely! Picture a company that faced a torque disaster – parts flying off like confetti at a New Year’s party. After switching methods and a little elbow grease, they turned their situation around and are now cutting it fine without a hitch. Talk about a glow-up!