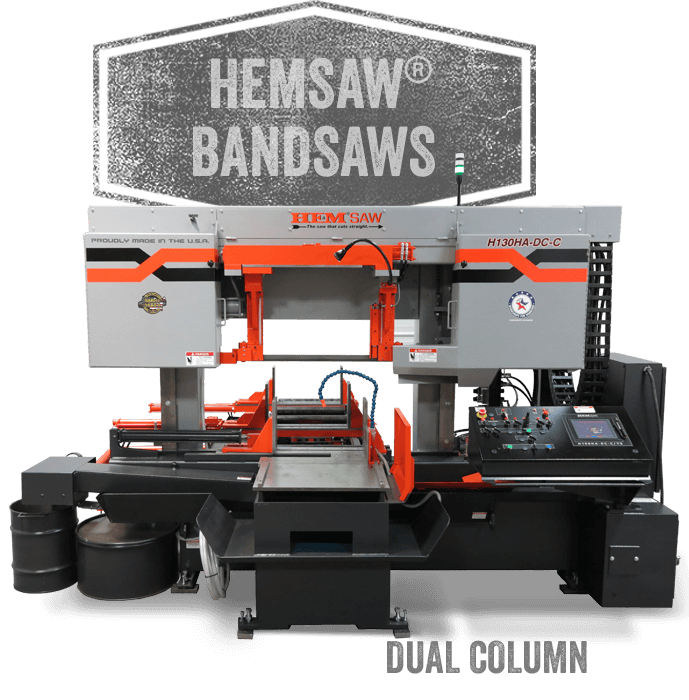

Cnc Band Saw Machine

How do you keep wood from jumping on a scroll saw

The similarities between the saws stem from their abilities. There are important differences.

Another heavy-duty machine that can do professional work. It includes a built-in lamp for halogen work.