Manual Band Saws Impact Fees

Baileigh Band Saw Parts

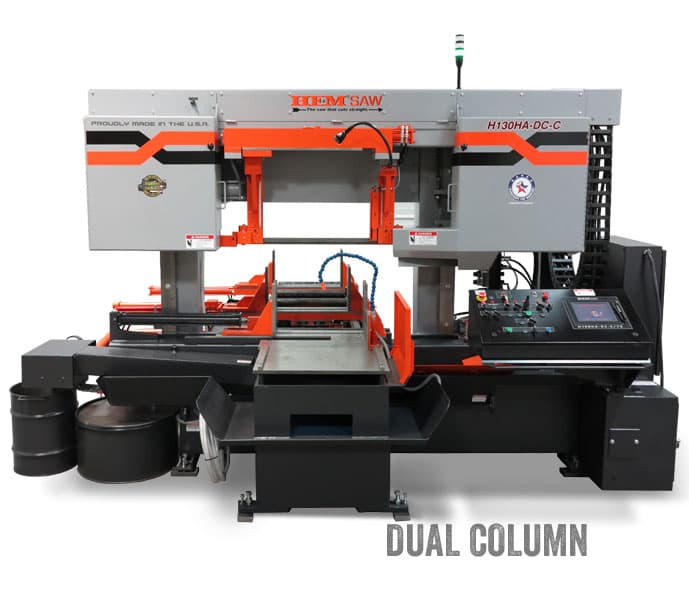

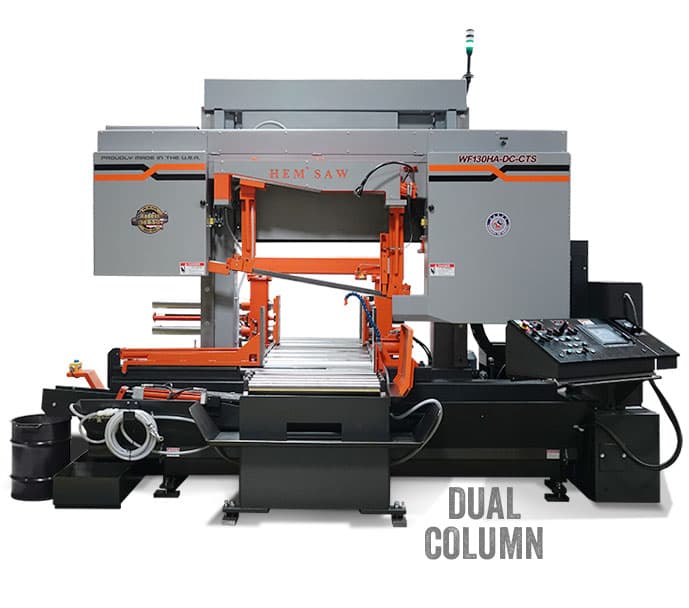

Generally, horizontal bandsaws can be found on the floor. They can be used to cut basic shapes with different materials.

The loop blade rotates between an idler wheel that is mounted above the table and the drive wheels, which are located below the table.