Manual Band Saws In Stock

Manual Band Saw 2429-20

It has many uses, including resawing large lumber pieces, processing small logs and making veneers.

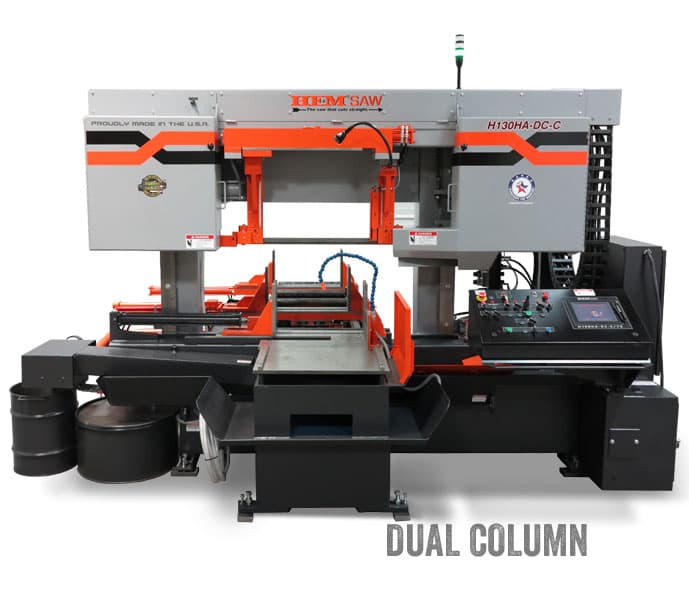

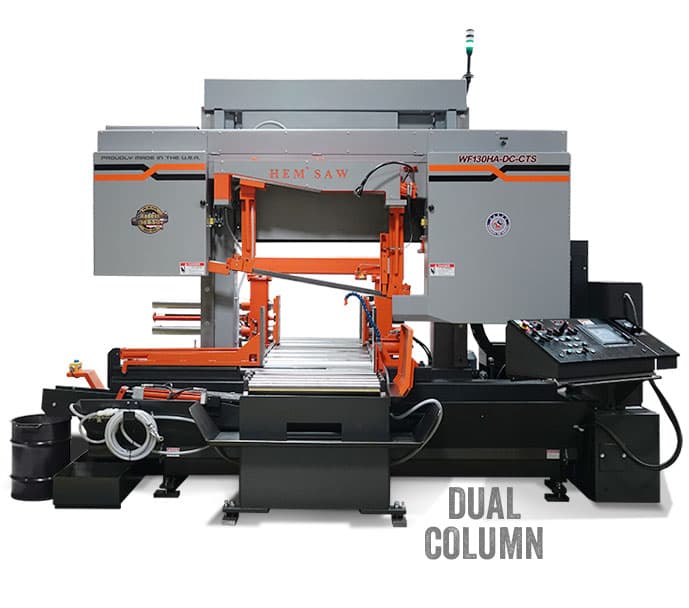

These are the most valuable type of bandsaw. These bandsaws are perfect for professionals and contractors with commercial cutting requirements.