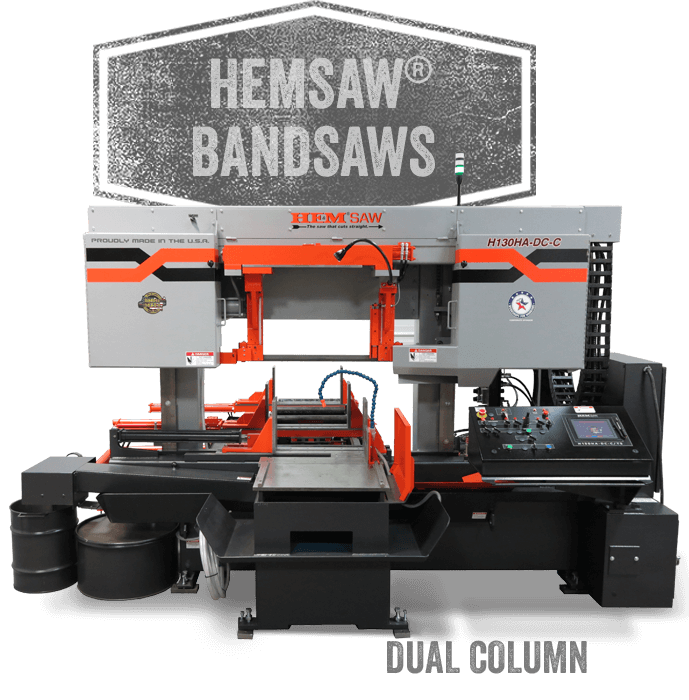

Band Saw Diagram

2nd Hand Band Saws

While there are bandsaws available for cutting metal, this article will primarily focus on non-ferrous and wood saws.

This saw stands out because of its amazing price. It's durable cast iron table will be appreciated as well as its compact size.