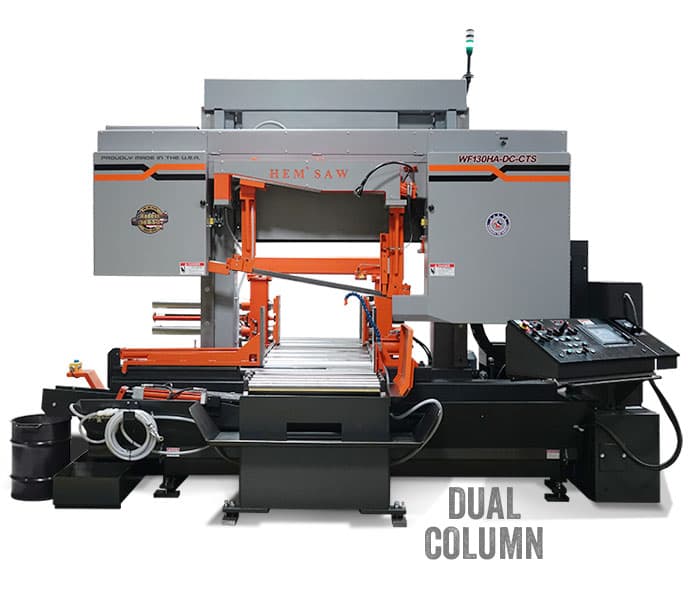

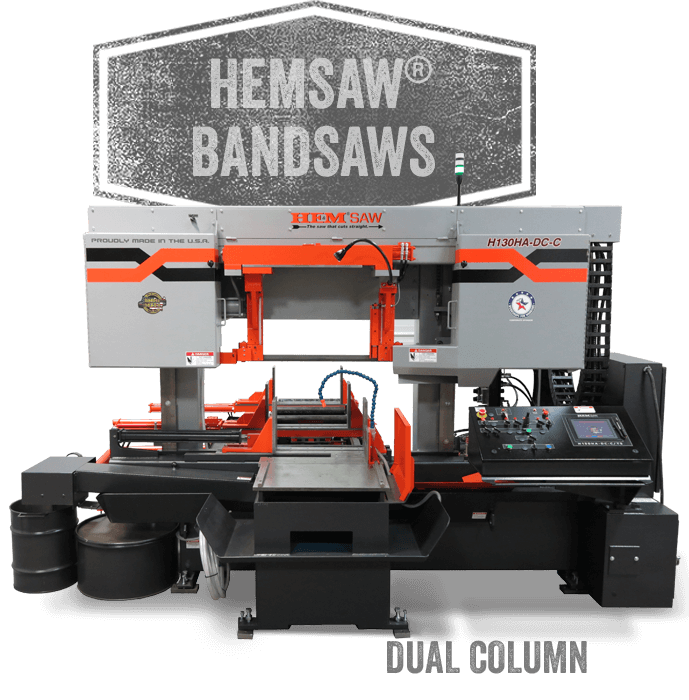

Second Hand Band Saws For Sale

Band Saw Cutting Machine

Band saws are able to make precise cuts as well as scroll saws. They can also be used for more complex cutting tasks. Band saws can handle harder materials.

It's also quite difficult to set this machine up initially. Another thing we were not thrilled about was the need to adjust and remove the belt in order to change speeds.

Second Hand Band Saws For Sale