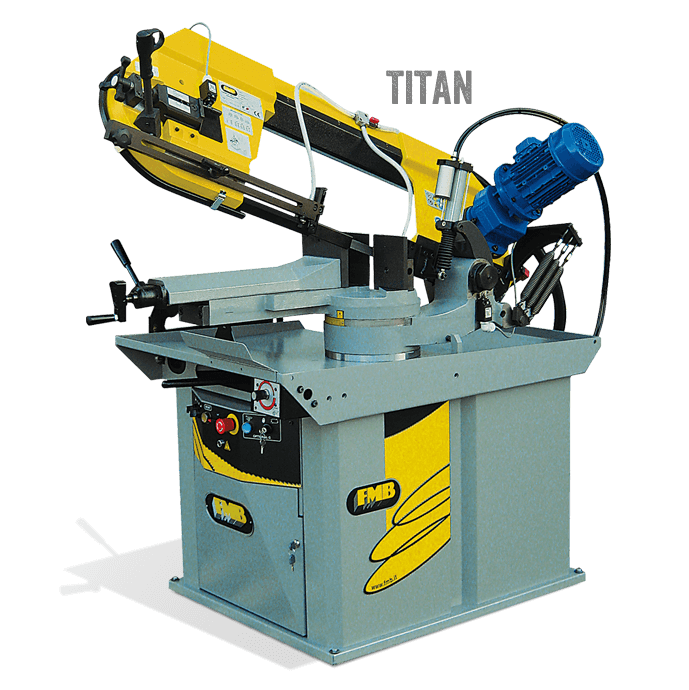

Bench Band Saws

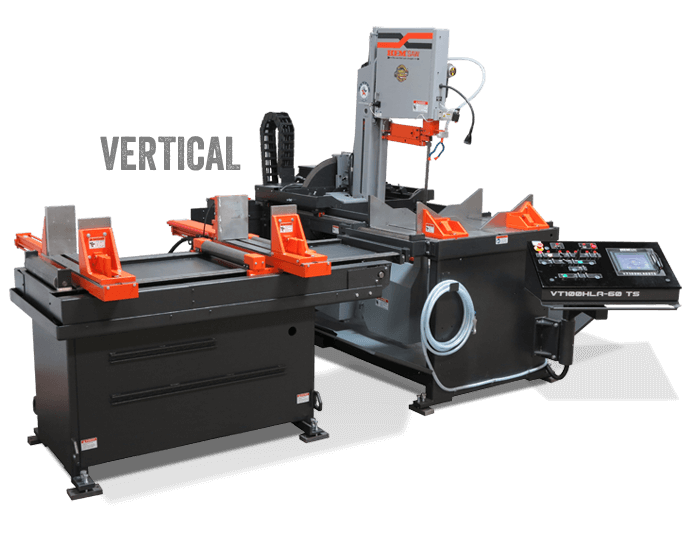

Industrial Vertical Band Saws

They have a smaller cutting area and are approximately the same size as hand-held circular saws. They are mostly used for job-site tasks.

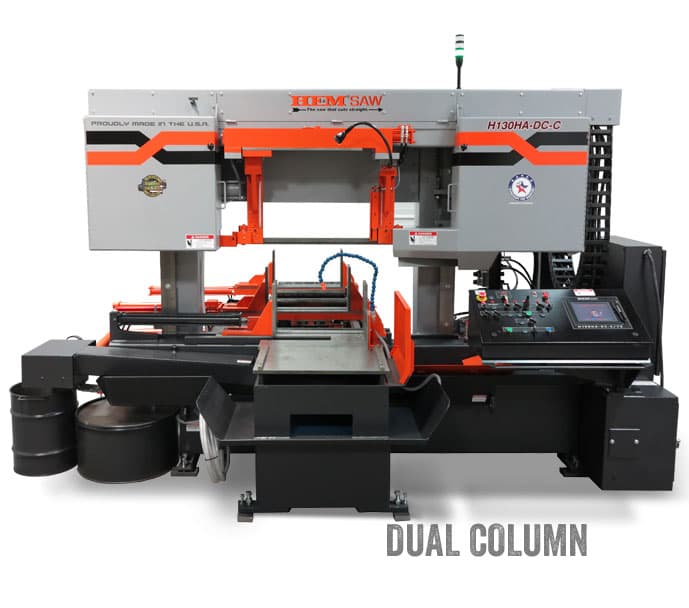

This bandsaw is over 300 pounds in weight and made of high-quality tubular Steel.