Band Saws Blades

Can a jigsaw replace a band saw

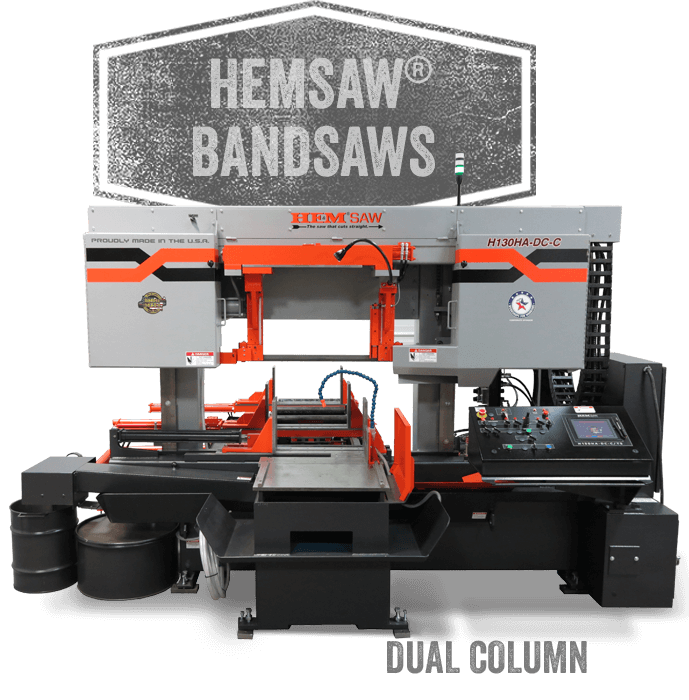

Fabricators and metalworkers need to have sawing and cutting tools because the core of fabrication relies on processing many materials. Our machines have computerized controls that ensure maximum precision and accuracy in their outputs. Metal pieces can be easily cut to different sizes and resized. These machines can be run manually or automatically.

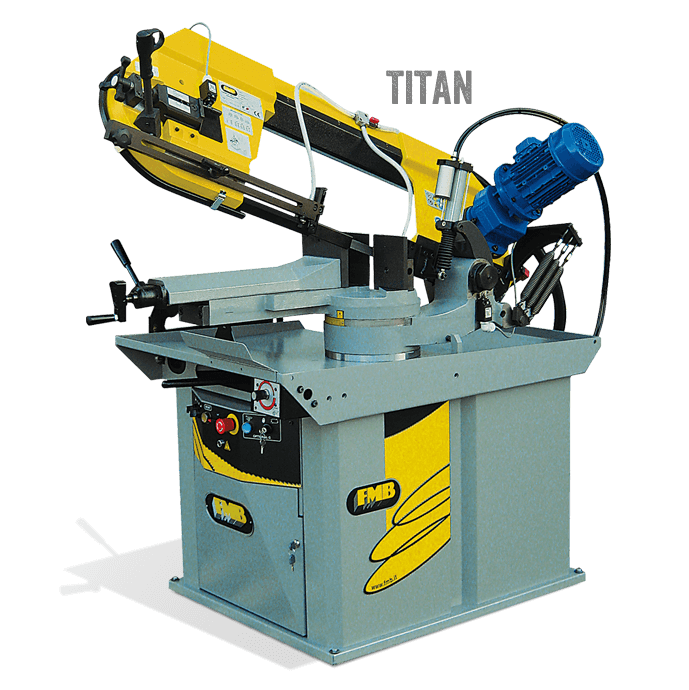

Band saws are used to cut wood, metal, and other materials. However, they are most commonly found in woodworking. We'll be looking at some great bandsaws in a variety of sizes and designs.