Amazon Band Saws

Variable Speed Band Saws

Blades with smaller teeth work best to cut metal, just as with other saws. A blade with more teeth is better for cutting wood.

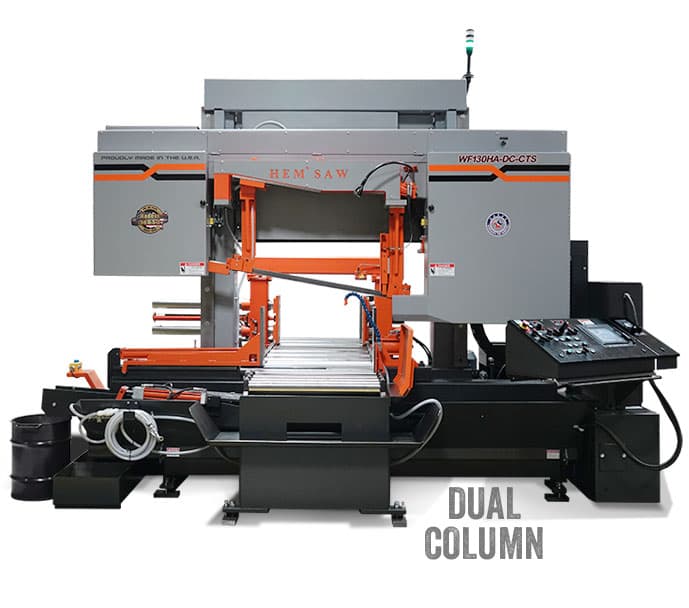

Our Auto Band Saws do not lack the versatility and functionality of our cutting and sawing machine range. We have 46 non-miter and miter options. Here are our auto bandsaws. They can be horizontal, vertical, dual column or vertical. This range is the perfect solution to maximize your output and increase your profitability in fabrication. Wouldn't that be great? You would, of course!