Band Saw Ebay Uk

Variable Speed

These pieces can be run along a fence or miter guide to quickly make smaller pieces.

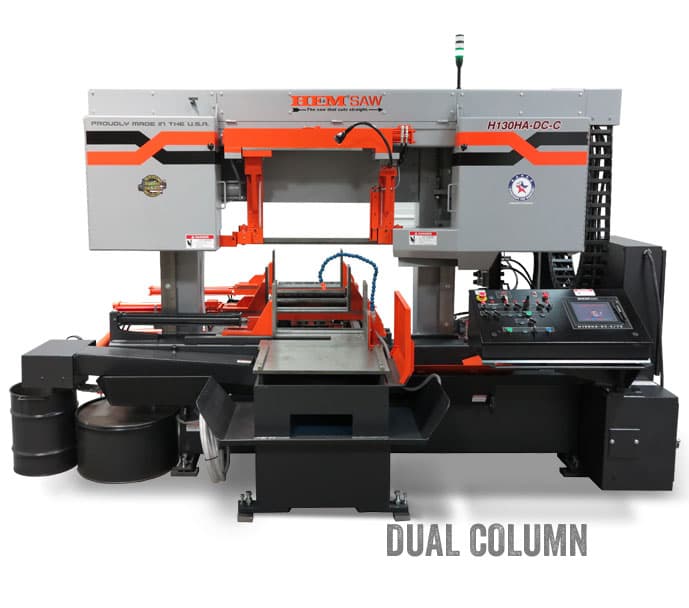

The machine is constructed with a heavy gauge steel frame that ensures strength and stability. This reduces vibrations during operation.