Benchtop Band Saws

Band Saw Rental

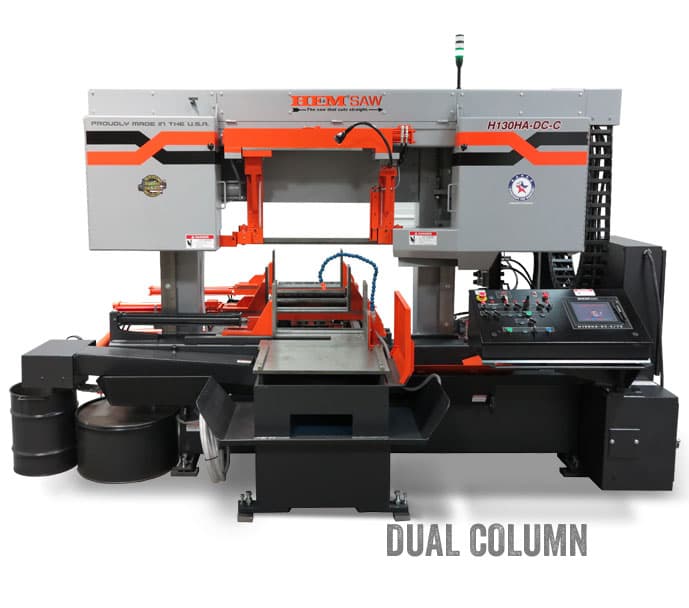

Band saws have blades that run in a continuous loop around their wheels. Band saws have a blade that cuts in a downward direction.

Contractors and builders use them to cut small workpieces. This is not uncommon for them to be used with metal or plastic.

Benchtop Band Saws