Band Saw Blade Welder

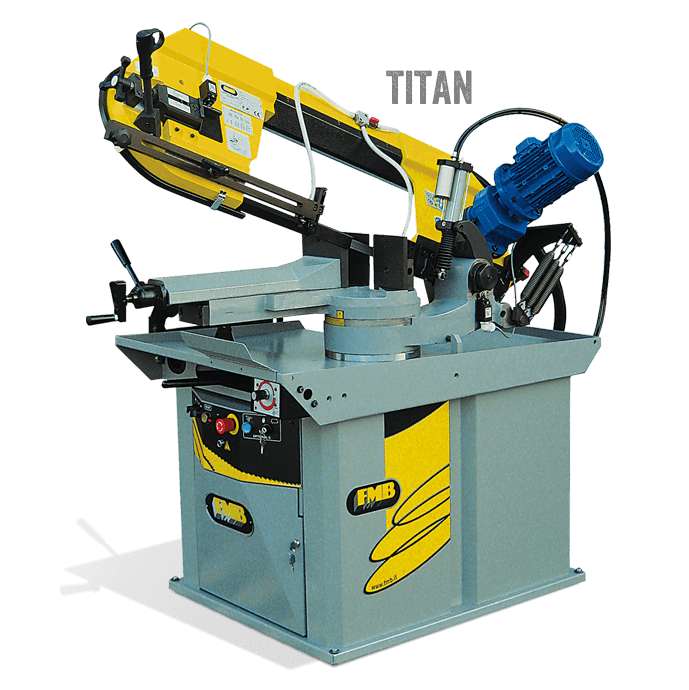

Cutting Machine

For easy tracking, the two aluminum rubber coated 9-spoke wheels are precisely balanced.

Your band saw can be used as a mini-mill. This can handle small logs. This can be done with wood from your yard.