Cutting Cnc

Each machine is equipped by our custom-developed VACAM control program. All machines have the same "look & feel", which drastically reduces learning curve. VACAM's platform is open and allows for easy exchange of production data with third-party ERPs and MRP programs. This provides you with up-to-date information about the progress of your project. VACAM shows you the flow of your processes and workflows. You can also instantly analyse imported products. The software automatically finds the best solution to any known problems. This allows you to produce without interruption, which increases efficiency and runs faster.

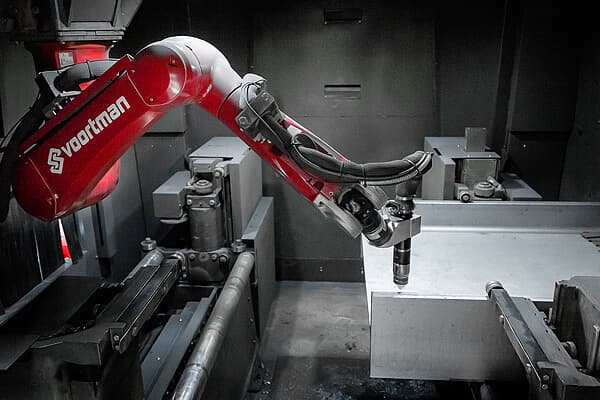

Coping is the best application process. The robotic plasma processor can be as close as possible to being an "all-in one" solution. A robot and a plasma unit can handle all kinds of processing, including rat holes and seismic structural connections like jayallan and "dogbone" cuts.