I-robots

We offer service for all types of structural steel fabrication machinery. Get in touch with us to arrange a service time.

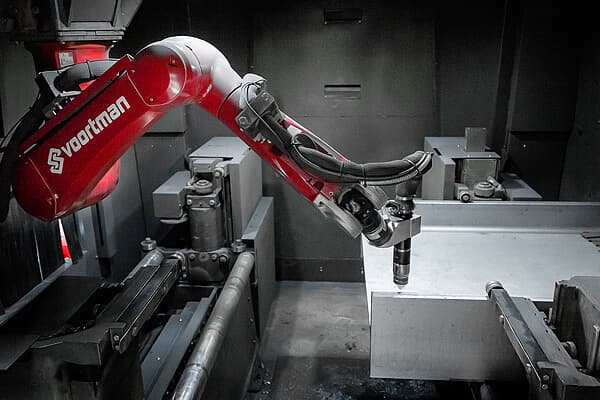

CNC coping is a fast, efficient way to process steel beams, tubes, and piping with superior accuracy. Partnering with the right steel coping manufacturer is crucial to achieving the precise, reliable results you need. Delta Steel is a leading steel coping supplier for a variety of structural applications. We use ultra-modern steel coping machinery that streamlines the steel fabrication process. Request a quote for pricing details or more information about our structural fabrication capabilities.