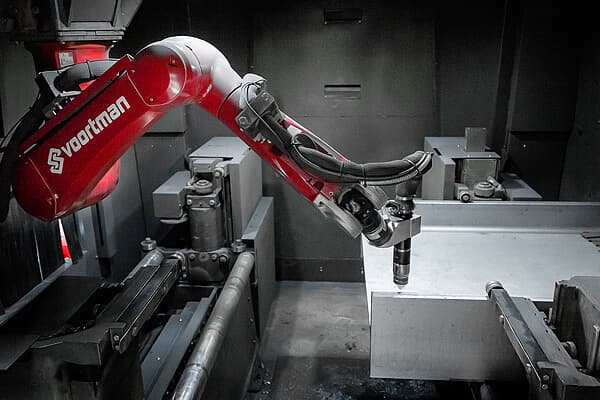

Robotic Coping Machines Good

Mac-Tech has a range of structural steel cutting and beam drilling machines. Some machines such as beam coping machines and CNC beam drilling machines may be more efficient than others. But you can rest assured that every piece of machinery in the list will provide the necessary structural beam coping or drilling.

Robotic Coping and Profiling can make your fabrication process more efficient. This system has been specifically designed for metalworkers and fabricators. It is able to work with angle lines, beam drilllines, hydraulic punches, ironworkers and band saws. This is a great way to improve your fabrication processes by taking them from zero to one hundred.