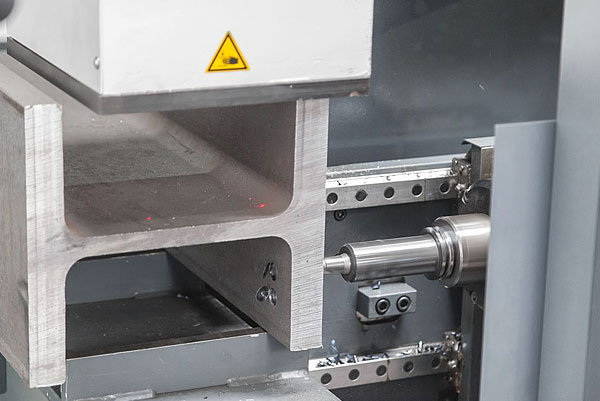

Cnc Beam Drill Line 2018

Automatic Edge Finder - The edgefinder can be used manual (Jogging Method and Screen Buttons), programmatically using M &G codes or fully automated with a dedicated program. This option sets offsets and rotates the program to match location and orientation on the cutting surface.

�..In an effort to meet customer demands and increase production, we have installed a new beam drill line the resulting reduced labor cost and quicker turnaround times have consistently helped usin landing quality jobs.