Akyapak 3

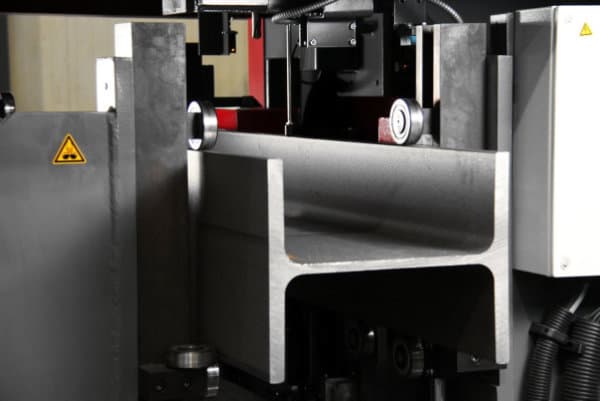

Voortman has developed today's CNC beam standard drill line using tried-and-true technology. Advantage-2 processes 150 ton of steel per workweek with the most efficient drilling/milling, scribing/taping, and countersinking operations.

Auto Standoff � This is not to be confused by vector standoff in 5-axis modes. Auto standoff works by using a changing surface. The angle of the Axis will determine how vertically it adjusts. With the buttons on your screen, you can make the vector-standoff change while the machine's running manually.