Which is stronger T-beam or rectangular beam

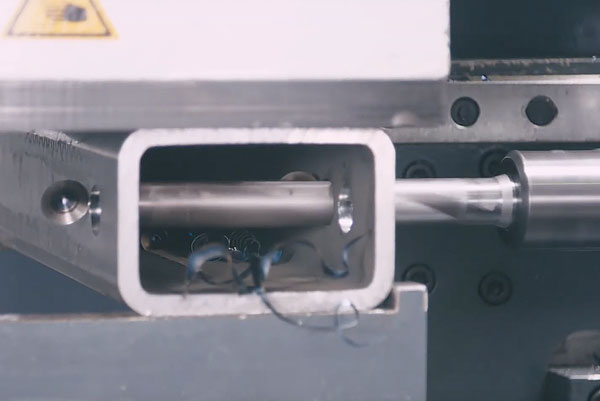

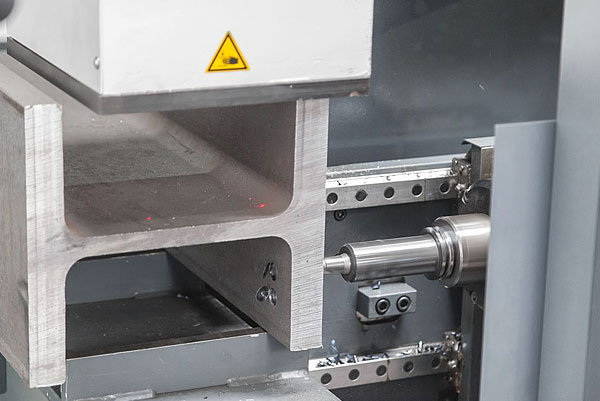

Advantage-2 carbide drills are equipped with electronic ball screw feed spindle motors and an automatic tool changer technology. Combining these features with Voortman�s well-known build quality as well as mechanical design, the result is a combination that combines agility and strength.

The CNC Beam Drill Line can be programmed manually at the machine or in the office using the supplied Peddimat software. This software comes included with the AVENGER and can be installed on as many PCs in your office as you choose � this unlimited license is included with the purchase of your machine. It is the same software that is found on the machine itself and is the same software used on the CNC Beam Drill Line and all Voortman CNC fabricating machinery.