Axminster Bandsaw

Fox Band Saws

These saws can be used to cut metal, PVC, and other materials at job sites. Instead of throat depth, vertical clearance, portable bandsaws define cut depth (blade x saw frame) or cut width (end x end of the exposed knife).

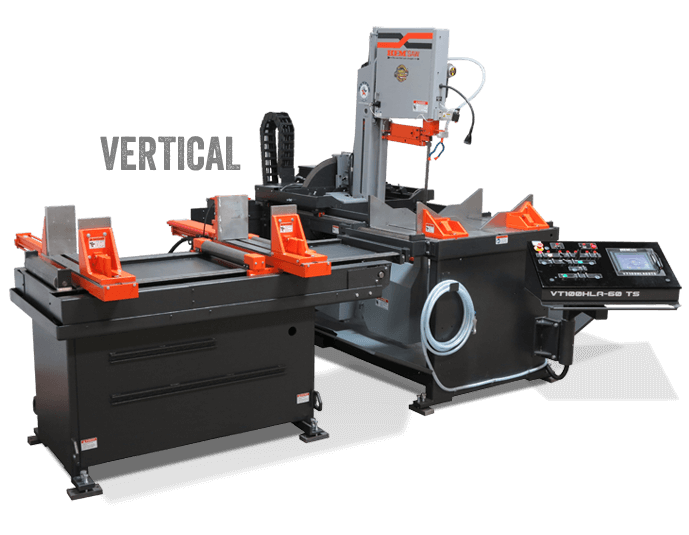

A band saw's cutting capacity and large size table make it easy to line up multiple pieces in a row.

Axminster Bandsaw