Band Saw Extension Table

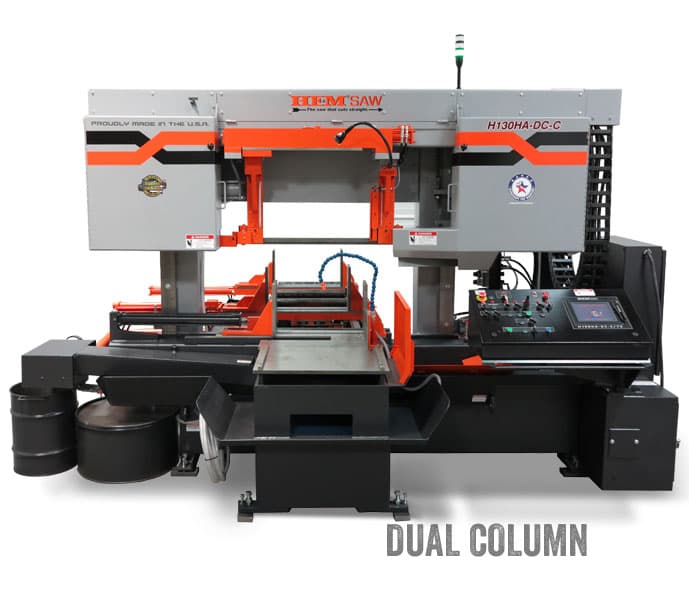

Band Saws For Metal

There are many types: Small Table Tops 8-9" (without a base), Small 10-14", Large 15-20", horizontal bandsaws, as well as handheld bandsaws. The tabletop ones won't take your business far. These machines can be used in small shops. The motors are fragile and your options for making a profit will be restricted by the clearance.

We also liked the ease of use for tracking adjustments on this saw. The warranty is five years.