Best Band Saws For Woodworking

Femi Band Saws

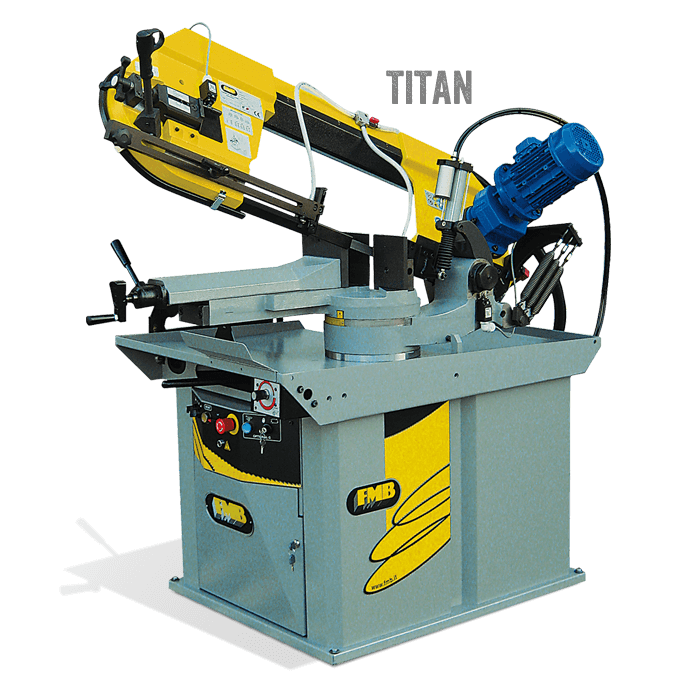

A simple blade tension and release mechanism features an electronic interlock feature. This prevents the bandsaw's accidental startup when the blade has been released or de-tensioned.

They also come at a fraction of the cost of floor standing saws. They can be attached on a flat, smooth surface. This will provide stability for the machine.

Best Band Saws For Woodworking