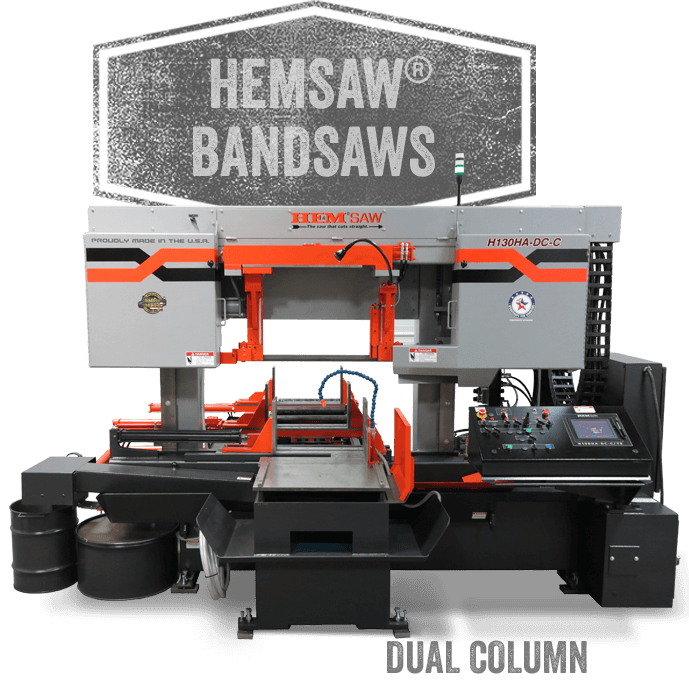

Band Saws

Band Saw Jig For Circles

The history and evolution of the band saw dates back a long time. We have many versions of this saw, and there were many before our current model.

The wheels are also made out of heavy cast-iron, which gives the blades more momentum, making it easier and faster to cut through hard materials.