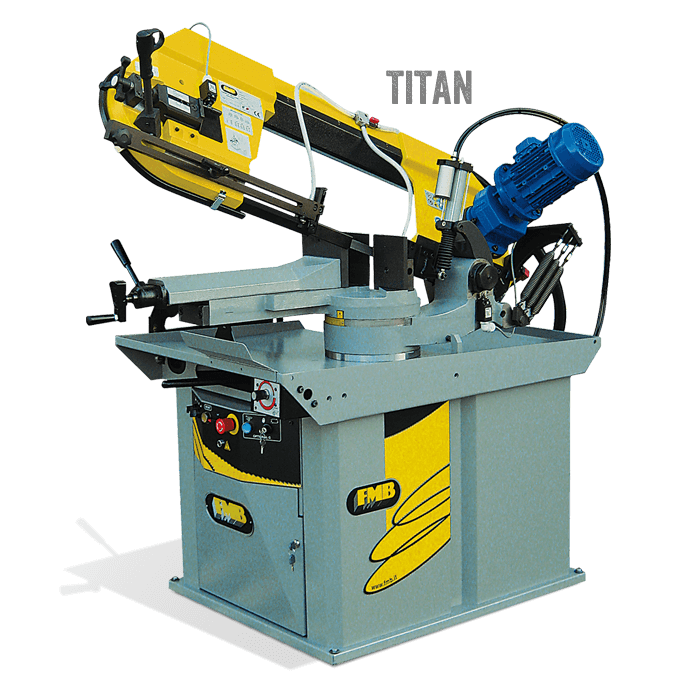

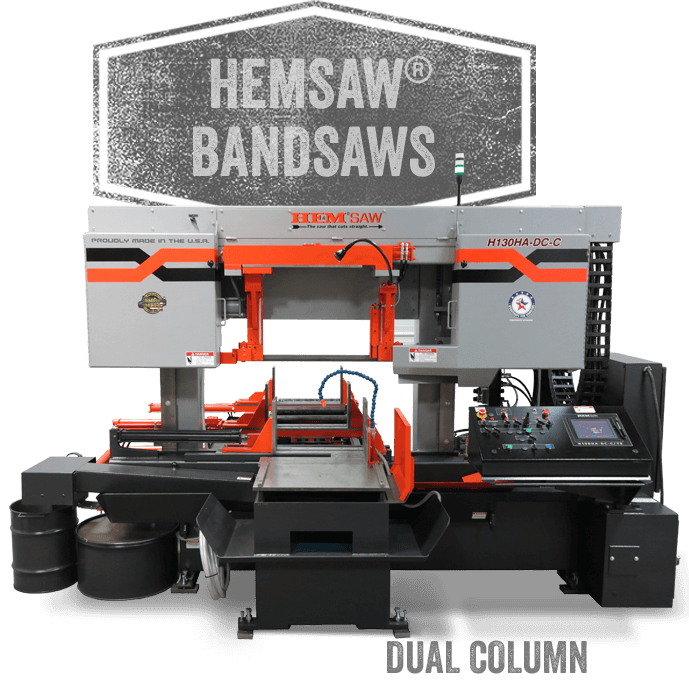

Band Saw Drawing

Tool

Although the saw is more costly than others, it has many great features and is well worth the money.

The band saw may not be very obvious, but it is one of many essential tools every woodworker should have.