Band Saw Definition

Stainless Steel

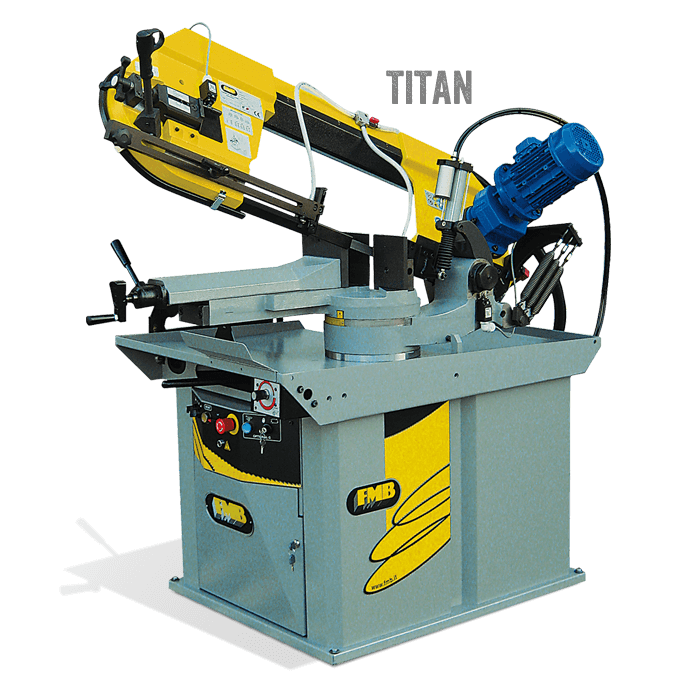

This skill saw is perfect for anyone looking for an 9-inch bandsaw. This portable benchtop bandsaw can be used even if you only have a small workspace.

To aid the blade's movement is a heavy-duty aluminum stand and cast aluminum tires with rubber tires.