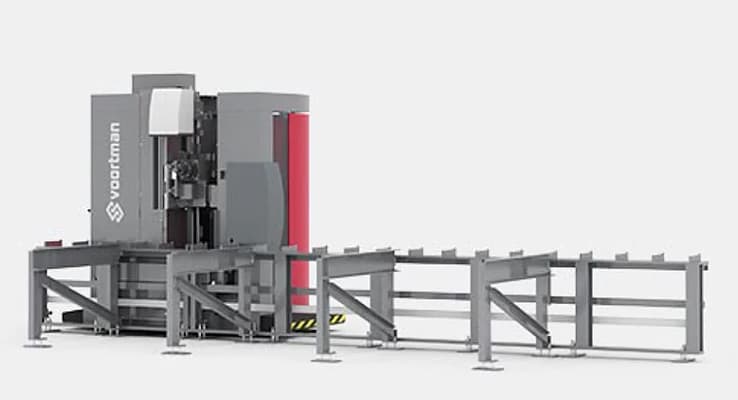

CNC Drill Line will not only drill columns and beams but can also process all types of steel profiles such as channel, angle, flat bars, base plates and RHS square and circular profiles.

Each of our beam drill line machines have linear guides, central lubrication, and a tool cooling system to ensure smooth operation and lower maintenance. Within each coordinate system there is a 4 station tool changer, allowing it to drill, mill, scribe, counter sink, or tap as needed; tools can even be swapped out mid-operation easily and without disruption. Positive beam positioning consists of an arm attached to a rack and pinion system on the feed conveyor to more accurately position the beam as it goes through the drill line, maintaining .004�, making our steel beam drill lines much more accurate than friction roller machines.