Cnc Drill Line Vendita Online

GSS Machinery is committed to offering you the best options for drilling with your CNC Drill Line, or any other CNC Beam Drill Line.

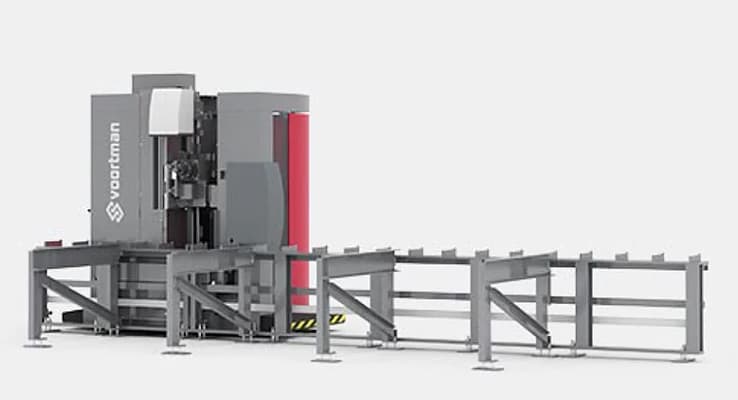

Voortman-designed beam drilling lines have intelligence not only in their own capabilities but also in the fact that they can be plugged into any environment because of their modularity. Tandem solutions, such as band saws with robotic coppers or PeddiWriters, expand the shop�s throughput positioning. It allows for a more cost-effective approach when the steel sector cools down and a more aggressive one when it heats. Voortman invented the Multmaster, which can be used to advance small parts into a tandem-bandsaw. Fabricators are more profitable when they use the whole profile and minimize the remnant. Do you want more output? Check. Material handling is key to any Voortman CNC drill-line profit. Fabricators not only lose money when a profile is manually moved but material handling is far safer than using fork trucks and cranes to move the largest profiles.